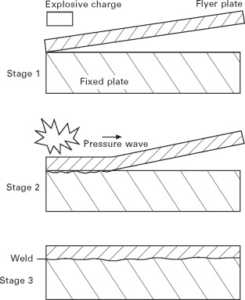

What is Explosive Welding?

Although welding has always been essential to industry and construction, our methods and technology also change as these sectors develop. Explosive welding is one technique that is becoming increasingly popular; it’s a process that sounds as dramatic as it is useful. However, what is explosive welding exactly, and why is it regarded as the next major innovation in the joining of the materials industry? Let’s explore this in more detail in this article. So, let’s begin.