Hi there, I’m Sean Xia, the founder of BaiChuan Precision. After graduating from college in 2000, I have engaged in CNC machining fields for more than 20 years. The company name “BaiChuan” also means “Better Cnc”, we always keep looking for better ways to provide more precision parts.

Precision aluminum CNC machining services are our area of expertise. In aluminum CNC milling service, OEM CNC parts surplus material is removed from raw materials to shape the OEM milling parts into a final product in accordance with a CAD/CAM design.

While CAD (computer-aided design) software determines the physical boundaries of OEM CNC machining parts. CAM (computer-aided manufacturing) software converts the dimensions of OEM CNC parts into aluminum CNC milling manufacturing instructions,

Additionally, machinists apply this approach to many aluminum CNC milling and production processes. All modern aluminum CNC milling manufacturers offer automation of the design and production of an OEM machining part, regardless of its individual production.

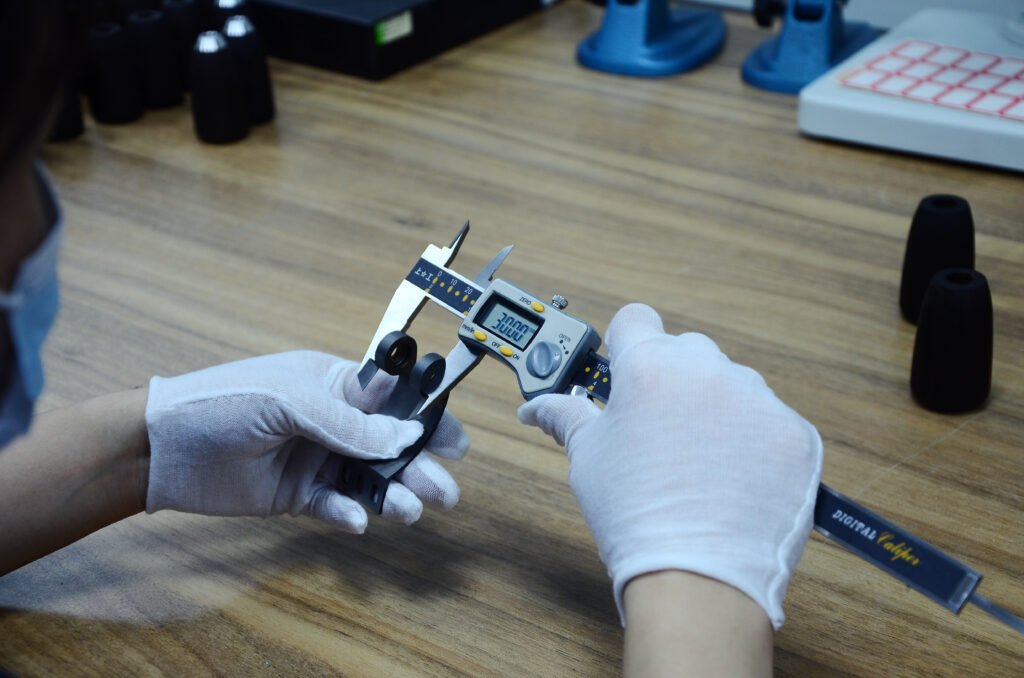

In OEM CNC parts, the same results are obtained after each measurement known as precision. Accuracy is closely a measurement that resembles the true or acceptable value.

OEM CNC milling parts is one of our main service expertise. Many of the essential properties of a product, including its diameter, true position, shape, and flatness, can be held within extremely tight geometric tolerances via aluminum CNC milling.

Aluminum CNC milling service is a popular option for a variety of tasks, from prototypes to the full-scale manufacture of one-of-a-kind precision components. It is becoming more and more cost-effective to purchase tooling and can produce a wide range of complex parts.

Computer numerical control (CNC) machines are automated machines that are run by computers that carry out pre-programmed controlled command sequences. The CNC machines are effectively the reverse of the “old-aged” equipment that can be manually operated by hand wheels or levers or mechanically automated by cams.

Modern CNC machines are able to comprehend and operate using the G-code a CNC machining language, which provides accurate production measurements including feed rate, speed, position, and coordination.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are used to specify the mechanical dimensions of the OEM CNC parts and convert those specifications into manufacturing instructions. As a result, the industry needs skilled OEM CNC part machinists and programmers to run this cutting-edge equipment.

The OEM machining parts can be manufactured using precise CNC machining but the design for any object must be created using CAD or CAM software before. To effectively recreate the OEM milling parts, a precise manufacturing process must follow the highly complex 3D blueprints created by these systems.

Aluminum CNC milling machines are a standard in industries all over the world that emphasize on OEM CNC milling parts, which gradually remove material from a workpiece using rotating tools. These machines use a variety of cutting tools along one or more axes to mechanically remove material from a workpiece.

This method can be used to OEM machining parts, a wide number of materials, including metal, plastic, glass, and wood, and to create a vast range of goods and parts with unique designs.

Precision aluminum CNC milling services cover a wide range of capabilities, including mechanical, chemical, electrical, and thermal operations.

Numerous industrial sectors, including those in the aerospace, shipping, automotive, oil drilling, pumping, and refining, as well as the medical, FMC manufacturing, and precision engineering fields, frequently use aluminum CNC milling machines.

The steps below make up the fundamental aluminum CNC milling process:

As the more complex the part, the more consideration is needed throughout the OEM CNC machining process. Design engineers should therefore place more focus on it and always strive to produce simple elements. Simple parts will be simpler to create, and they’ll be more affordable too.

The greatest approach to creating designs that may be executed with ease and excellent performance is always taken into consideration by a professional design team. It guarantees increased productivity and efficiency at the most competitive prices possible to fit the client’s budget.

The human error that frequently happened throughout the design process can be decreased by using aluminum CNC prototype machining services. These mistakes, which typically occur during measurement and production, can severely ruin projects and goods.

More complex components require 5-axis machining since it can accurately achieve the final shape while working on 5 different angles and axes. Additionally, it benefits from a single setup and saves time.

However, only a skilled and experienced manufacturing team with greater competence in Aluminum CNC milling Prototype Machining Services can guarantee the precision of tools and OEM CNC parts. We can guarantee a quick lead time.

We tried to work with B2B platforms and trading companies before.Since machining industry contains preciseness and high-technology,

the middleman couldn’t show their respect to clients’ designs and machining industry if we contact the clients through them, so we hope that there is a opportunity to have a direct dialogue with clients throughout this website to turn the excellent designs into finished products from drawings.

Kunshan Baichuan Precision Components Co., Ltd

Address: Building 1, No.525 Maoxu Road, Kunshan 215300, Jiangsu, P.R.China

Email: sales92@partstailor.com

Phone: +86-18551199566

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.