Exploring the cutting-edge of industrial fabrication, Friction Stir Welding (FSW) emerges as a pivotal technology in vacuum chamber manufacturing. Discover how this innovative welding process enhances efficiency and quality in critical applications.

Friction Stir Welding (FSW) is a solid-state joining technique that uses a non-consumable tool to create high-strength joints without melting the base materials. Ideal for sensitive manufacturing environments like vacuum chambers, FSW offers enhanced joint integrity, reduced distortion, and high durability, making it indispensable in industries requiring impeccable vacuum seals and structural strength.

But why is FSW particularly transformative for vacuum chamber production? Let's delve deeper.

What is Friction Stir Welding and How Does It Work?

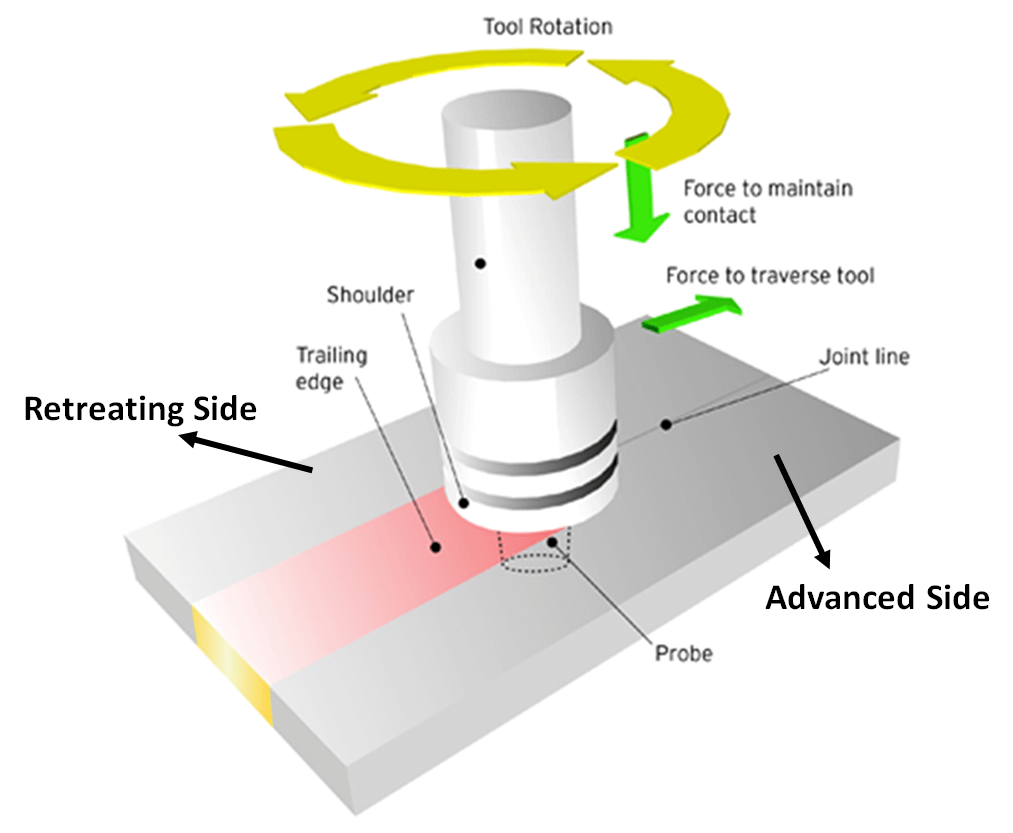

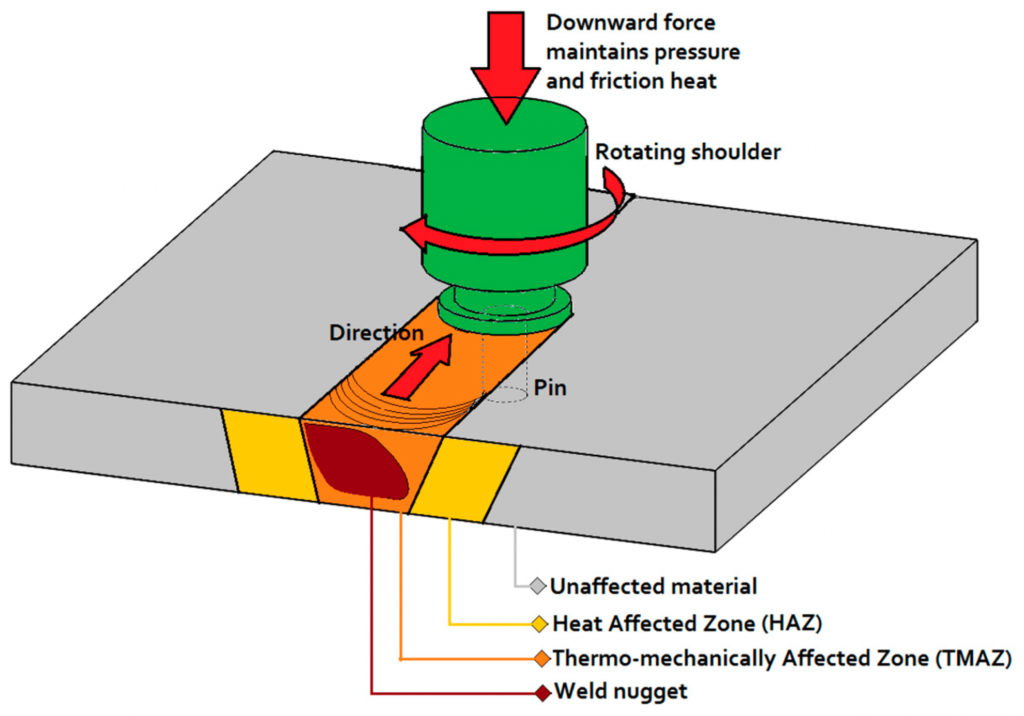

Friction Stir Welding utilizes a specially designed rotating tool to generate frictional heat, which softens the material. The tool then mechanically mixes the workpieces to form a high-strength bond. This technique is crucial for maintaining the pristine properties of the base materials, a key requirement in vacuum technology. The process avoids the common pitfalls associated with traditional welding, such as porosity and cracking, which are detrimental in vacuum applications where any leak or imperfection can invalidate the entire system's integrity.

Technical Breakdown of the FSW Process

The FSW process involves several key parameters: tool design, rotation speed, welding speed, and downforce. Each of these elements must be precisely controlled to ensure optimal welding conditions. The tool design is particularly crucial because it affects how the material flows around the tool, influencing both the quality and strength of the joint. Engineers continually refine these parameters to adapt FSW for different materials and applications.

What is Friction Stir Element Welding?

Friction stir element welding, a subset of FSW, focuses on achieving precise temperature control to avoid defects in the weld seam. This precision ensures that the mechanical properties of metals used in vacuum chambers are not compromised, thereby maintaining the structural integrity and vacuum seal. This process is particularly valuable in environments where thermal expansion and other heat-related deformities must be minimized.

Why Use Friction Stir Welding in Vacuum Chamber Industries?

FSW is cost-efficient as it reduces material wastage and energy consumption. It can join a range of dissimilar materials, a common requirement in vacuum chamber construction. The controlled welding process prevents material deformation, ensuring that each chamber maintains its precise specifications for optimal performance. Additionally, FSW is environmentally friendly as it produces no fumes or emissions, which is particularly important in clean-room environments often associated with vacuum chamber fabrication.

Comparing Traditional Welding Techniques with FSW

Unlike traditional welding, which often involves melting and could introduce impurities or structural weaknesses, FSW produces a clean, strong joint without altering the material's fundamental structure. This is particularly advantageous in vacuum chambers where even minor imperfections can lead to failures. Traditional methods also typically require post-weld treatments such as machining or polishing, which are not needed with FSW, thereby reducing production time and costs.

Materials Suitable for Friction Stir Welding

FSW is versatile in its material compatibility. It is particularly effective with aluminum, titanium, and stainless steel—materials commonly used in the construction of vacuum chambers. These materials benefit from FSW's ability to provide strong, durable welds without susceptibility to corrosion or thermal distortion. Exploring the specific properties of these materials and their reactions during the FSW process reveals why this method is superior for the precise demands of vacuum chambers.

Advanced Applications and Future Trends

The application of FSW is not limited to just vacuum chambers; it is also being adopted in other industries such as aerospace, automotive, and marine for its robustness and reliability. The future of FSW looks promising with ongoing research into automating the process using robotics and exploring its potential in joining more challenging materials like high-strength steels and composites.

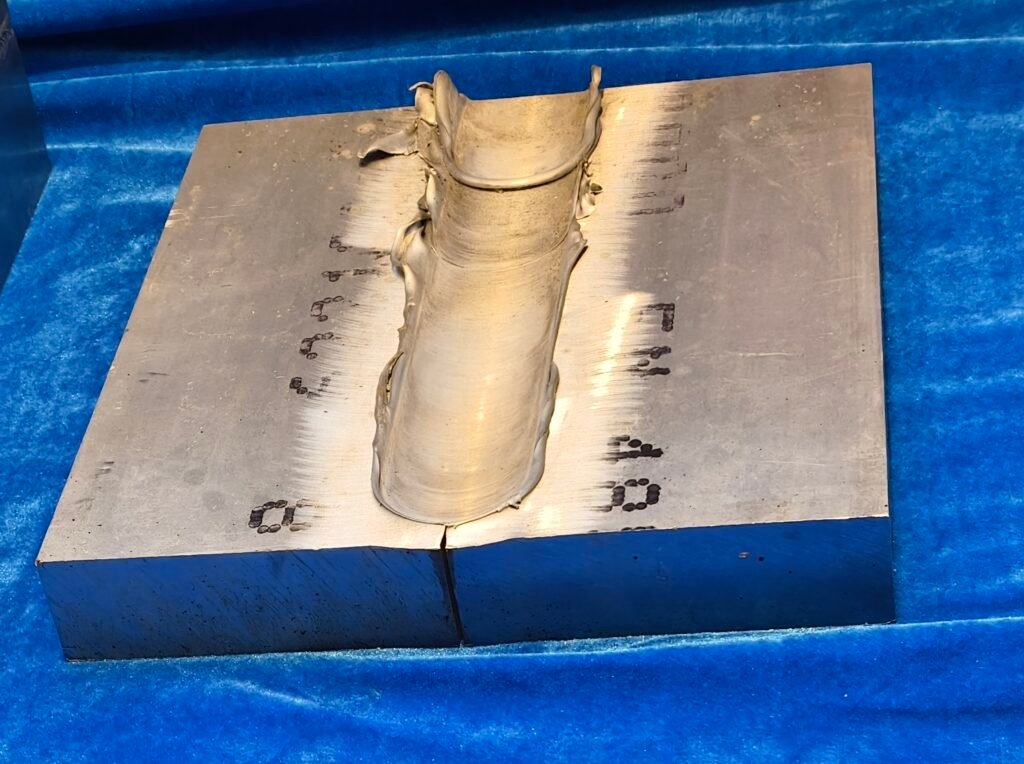

Case Studies: Success Stories of FSW in Vacuum Chambers

Several leading manufacturers in the aerospace and semiconductor industries have turned to FSW to enhance the reliability and efficiency of their vacuum chambers. These case studies demonstrate significant improvements in production rates and reductions in defect rates, emphasizing FSW's role in advancing manufacturing standards. Detailed examples from companies like SpaceX and Intel show the practical benefits of implementing FSW in their production lines, including faster turnaround times and enhanced quality of the final product.

In conclusion, Friction Stir Welding not only optimizes manufacturing processes but also propels the vacuum chamber industry forward through technological advancements. Its ability to maintain material integrity and ensure high-quality welds offers a substantial edge in a highly competitive market. As industries continue to seek out innovations that improve efficiency and performance, FSW stands out as a key technology driving future developments.