What is Friction Stir Welding?

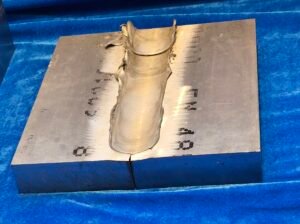

Friction stir welding (FSW) is a solid-state welding technique that forms the weld seam by manually stirring the metal to create friction heat and feeding a spinning tool along the joint line between two workpieces.

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

Friction stir welding (FSW) is a solid-state welding technique that forms the weld seam by manually stirring the metal to create friction heat and feeding a spinning tool along the joint line between two workpieces.

Welding is a material joining process where two or more parts are coalesced at their contacting surfaces through the application of heat and/or pressure.

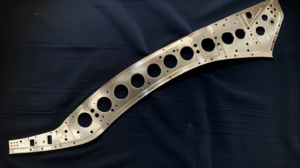

Thin wall machining is a CNC machining process focused on creating precise cuts and shapes in materials with thicknesses typically less than 2mm. Its main objective is to manufacture intricate components with delicate, thin features that demand the utmost accuracy.

Vacuum chambers are integral to numerous scientific, medical, and industrial applications, necessitating extremely high standards of accuracy and reliability. Proper post-processing is crucial in ensuring these standards are met by enhancing the physical and chemical properties of the chambers. This comprehensive guide explores the sophisticated post-processing steps such as cleaning, heat treatments, and surface treatments that are essential for crafting top-quality vacuum chambers.

Welding is an indispensable technique across various industries, pivotal for constructing everything from small tools to large infrastructures. Its applications in precision manufacturing, especially in making vacuum chambers, underscore the critical role of choosing the right welding process for specific materials.

Friction Stir Welding (FSW) is a solid-state joining technique that uses a non-consumable tool to create high-strength joints without melting the base materials. Ideal for sensitive manufacturing environments like vacuum chambers, FSW offers enhanced joint integrity, reduced distortion, and high durability, making it indispensable in industries requiring impeccable vacuum seals and structural strength.

When selecting a material for vacuum chambers, aluminum offers lightweight properties and cost-effectiveness, stainless steel provides durability and corrosion resistance, and titanium stands out for its superior strength-to-weight ratio and exceptional corrosion resistance.

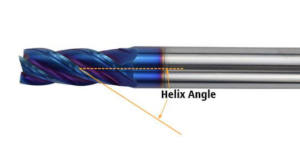

Helix angle has a major impact on power needs, vibration, and chip control. This article explores the idea of a helix in machining, outlining the benefits and drawbacks and offering the best helix angle options for particular uses.

Injection molding flash represents a flaw arising from the escape of molten plastic outside the mold during the injection process, leading to solidification. This issue not only diminishes the overall quality of the molded component but also poses a risk to the integrity of the mold itself.

A crucial player in CNC milling, the fly cutter significantly impacts the finishing of large, flat surfaces. The choice of milling machine and cutter in CNC operations is pivotal for surface quality and machining speed. With a plethora of milling cutters available, understanding the fly cutter is essential.

Find out a better solution for manufacturing beech chairs in Baichuan Precision!

As manufacturing evolves, lean principles serve as a compass, driving continuous improvement, streamlining processes, and embracing innovative technologies to deliver quality products swiftly and cost-effectively.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.