Computer numerical control (CNC) machines are a critical aspect of modern manufacturing, providing precision and efficiency in various industries. However, like all machinery, CNC machines require proper maintenance to ensure their optimal performance, especially during the harsh winter season. The cold and dry conditions of winter can cause various issues, such as rust, static electricity, and power surges, that can damage the machines and affect their precision. Therefore, it is crucial to maintain CNC machines regularly during the winter season to prevent any potential issues and ensure their longevity. In this article, we will discuss ten essential tips on how to maintain CNC machines in winter, covering critical aspects such as temperature control, lubrication, air compressors, power supply, machine covers, regular maintenance, cleaning, humidity control, electrical components, and operator training. By following these tips, you can ensure the proper functioning of your CNC machines and maintain their efficiency, even in the harshest winter conditions.

Temperature Control

During winter, the temperatures can drop significantly, which can cause problems with the CNC machines. For instance, if the temperature is too cold, the machines may not operate correctly due to thermal expansion and contraction. Also, if the machines are too warm, they may overheat and malfunction.

To prevent these issues, it is essential to maintain a stable temperature in the machine shop where the CNC machines are located. You can achieve this by installing heating systems that keep the temperature within a specific range. For instance, you can install a central heating system that keeps the room warm. If you do not have a central heating system, you can use portable heaters to keep the area warm. However, it is essential to ensure that the portable heaters are placed away from the machines to avoid any electrical hazards.

Lubrication

Lubrication is critical for the proper functioning of CNC machines. In winter, lubrication can become thicker and harder to apply, which can cause issues with the machines. Therefore, it is necessary to use appropriate lubricants that can withstand low temperatures.

For instance, you can use lubricants with low pour points. Low pour point lubricants remain fluid even in cold temperatures, making them suitable for use in winter. Also, you can use synthetic lubricants that can withstand extreme temperatures and pressure. Synthetic lubricants have a higher viscosity index, which means they remain stable even in cold temperatures.

It is also essential to check the lubrication systems regularly and maintain them appropriately. For instance, you should check the oil levels and refill them if necessary. You should also check the oil filters and replace them if they are clogged.

Air Compressors

Air compressors are essential in CNC machines, as they help to clean the cutting area and keep the machines running smoothly. However, in winter, the air compressor's moisture trap can become clogged, leading to a drop in pressure. This can cause the machines to malfunction or even break down. Therefore, it is vital to check the moisture trap regularly and drain it if necessary. In addition, it is advisable to keep the air compressor and its components away from any direct exposure to cold temperatures.

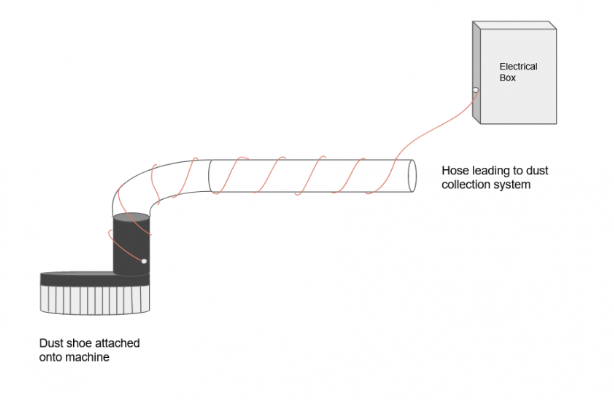

CNC Machining Dust cleaning system

Power Supply

Power supply issues can cause severe damage to CNC machines. In winter, power outages are more common due to harsh weather conditions. Therefore, it is crucial to have a backup power supply to ensure the machines continue to operate in the event of a power outage. This can be achieved through the use of uninterruptible power supply (UPS) systems, which provide power in the event of an outage. The UPS systems must be checked regularly and maintained appropriately to ensure they function correctly.

Machine Covers

Machine covers are essential in protecting CNC machines from dust, debris, and other harmful elements. During winter, machine covers also provide a layer of insulation, keeping the machines warm and protected. It is vital to ensure the machine covers are in good condition and free of any holes or tears that can allow cold air to penetrate.

Regular Maintenance

Regular maintenance is essential in ensuring the proper functioning of CNC machines, especially during winter. It is advisable to have a maintenance schedule that covers all the critical aspects of the machines, including lubrication, cooling, and electrical components. A maintenance schedule ensures that the machines are checked regularly, and that any issues can be detected early before they cause severe damage.

Humidity Control

Humidity control is critical in ensuring the proper functioning of CNC machines during winter. High humidity can cause condensation to form on the machines, leading to corrosion and rust. On the other hand, low humidity can cause static electricity to build up on the machines, leading to malfunctions.

Static electricity build-up is a significant concern for CNC machines during the winter season. Static electricity is an electric charge that builds up on the surface of an object, such as the surface of a CNC machine. This build-up of electric charge can be caused by friction between two materials or by changes in temperature or humidity. When static electricity build-up occurs, it can cause several problems for CNC machines, including damage to sensitive electronic components and incorrect readings from sensors.

One of the primary causes of static electricity build-up during the winter season is the dry air. As the humidity drops during the winter, the air becomes drier, which can lead to an increase in static electricity build-up on the surface of CNC machines. The dry air causes the electrons on the surface of the machine to become more mobile, which leads to an imbalance of electric charge.

To prevent static electricity build-up on CNC machines during the winter season, it is essential to maintain proper humidity levels in the machine shop. Using humidifiers or other moisture control devices can help to maintain a consistent level of humidity, which can reduce static electricity build-up on the surface of CNC machines. Additionally, it is crucial to ground the machines and use static dissipative materials to reduce the build-up of static electricity. Regular cleaning of the machines can also help to reduce the accumulation of dust and debris, which can contribute to static electricity build-up. By following these steps, you can reduce the risk of static electricity build-up on your CNC machines and ensure their optimal performance during the winter season.

Electrical Components

Electrical components are critical in the functioning of CNC machines. During winter, electrical components can be affected by power surges and voltage drops due to changes in temperature and humidity.

To prevent these issues, it is essential to install surge protectors and voltage regulators to protect the electrical components from power surges and drops. Also, you should check the electrical components regularly and ensure that they are properly grounded.

Operator Training

Operator training is critical in ensuring the proper functioning of CNC machines. During winter, operators need to be aware of the potential issues that can arise and how to prevent them.

Therefore, it is essential to provide training to the operators on how to maintain the machines during winter. The training should cover all the critical aspects of the machines, including temperature control, lubrication, air compressors, power supply, machine covers, cleaning, humidity control, and electrical components.

Conclusion

Maintaining CNC machines during winter is essential to ensure their proper functioning and longevity. Temperature control, lubrication, air compressors, power supply, machine covers, regular maintenance, cleaning, humidity control, electrical components, and operator training are critical aspects to consider when maintaining CNC machines during winter. By following these tips, you can prevent potential issues and ensure the smooth functioning of your CNC machines even during the harshest winter conditions.