- sales92@partstailor.com

- +86-18551199566

Empowering Smart Manufacturing for Electronic Components: From design to manufacturing, we provide diverse material options, including aluminum alloy, steel, titanium alloy, and plastics, helping your electronic components achieve a leap in performance.

The electronics industry is the core engine of technological innovation, and precision manufacturing is the key to driving its development. From semiconductor chips to precision components, every advancement requires the highest quality materials, processes, and equipment. Baichuan excels in providing custom-engineered solutions, tailoring our advanced CNC machining and welding capabilities to meet the unique and demanding specifications of the electronics industry

Baichuan Precision accepts 2D drawings (.DWG, .DXF) and 3D models (.STEP, .IGES, .X_T) formats; our engineers are available 24/7 to provide drawing optimization services and timely feedback. You can also send samples for us to work from

Baichuan Precision has accumulated a vast industry database and a wealth of case studies, giving us extensive industry experience. Our welding team is spearheaded by an expert boasting over 40 years of experience in the field.

We boast a complete industry chain service, equipped with a Class 1000 cleanroom and a variety of advanced testing equipment, ensuring that our products meet the highest standards at every stage.

We have established trusted partnerships with customers across various industries. With a reliable global supply chain, we always prioritize confidentiality, ensuring the security of your project information.

We provide mission-critical components to global innovators in a variety of industries, including aerospace and the semiconductor industry.

Our 24/7 engineering team ensures that you’re on track from prototype to production – that’s why 100 + companies rely on our responsive manufacturing ecosystem.

We offer customized solutions from medical-grade components to large semiconductor vacuum chambers with max precision (±0.005 mm).

We deliver precision 3D-printed prototypes in metals/plastics with 24-hour quoting and for complex geometries CNC can’t handle.

A professional welding team led by more than 30 years of senior welding engineers with US semiconductor certification.

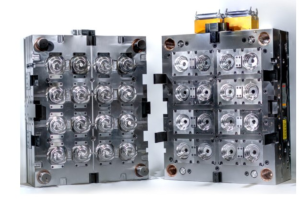

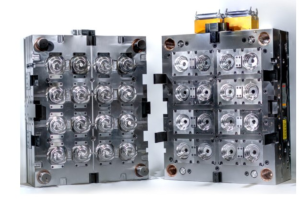

We can render assistance in foreseeing potential design issues, creating prototypes, and producing injection molds to lower the costs that have been ballooning for you in recent years.

Embracing a culture of quality excellence, our company is certified to ISO 9001:2015, demonstrating our commitment to customer satisfaction and our capability to consistently deliver high-quality products and services. To ensure precise validation of part conformity, we adhere strictly to drawing specifications and employ a comprehensive suite of precision metrology equipment, including Coordinate Measuring Machines (CMMs), for full-dimensional inspection. Detailed inspection reports are provided, guaranteeing that every delivery meets our clients’ stringent requirements.

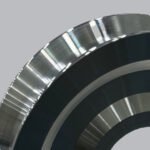

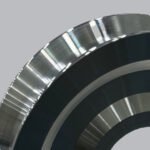

Explore our product showcase, featuring products designed specifically for the electronics industry.

This is an electrochemical process that enhances the corrosion resistance, wear resistance, and insulation of metals by forming a corrosion-resistant oxide layer on the metal surface, and can also be dyed to obtain different colors and appearances.

Polishing is a process of reducing the surface roughness of a material by mechanical, chemical, or electrochemical methods to obtain a smooth surface, aiming to improve finish, remove surface defects, improve appearance, and reduce friction.

Sandblasting is a surface treatment technique that cleans, deburrs, etches, or changes the surface roughness of a material by blasting abrasive materials onto the surface at high speed, and can remove surface oxide scale, rust, oil stains, etc., and change the roughness of the surface to increase friction or adhesion.

Uses electrochemical methods to deposit a metal coating on the metal surface to improve corrosion resistance, wear resistance, or appearance. Electroplating is widely used in the electronics industry to improve conductivity and prevent corrosion. Common electroplating materials include gold, silver, nickel, chromium, copper, and zinc.

Normally, we will provide a quote within 12 hours. If the information you provide is comprehensive, it will allow us to quote you faster.

As an ISO-9001 certified factory, we will strictly follow the tolerance requirements on your drawings. We can provide relevant reliability test reports. For example, High Temperature High Humidity Reverse Bias (H3TRB) test, Temperature Cycling (TC) test, etc.

Yes, our company has a team of specialized application engineers who can provide support in various areas. Our engineers have extensive machining and manufacturing experience, understand the complexities of design, and are prepared to reverse engineer projects. They are committed to supporting your project throughout the process and bringing your vision to life. We also offer a bespoke service where expert engineers with 40 years’ experience will provide one-to-one quotes and customization to your needs.

CAD Files in Any Format: Whether it’s 2D or 3D, we accept STP, IGES, X_T, DWG, PDF, STL, ensuring no design is too complex for us to handle.

Project Specifics: Share your expected quantities, desired machining processes, and material requirements to help us tailor our services perfectly to your needs.

Finishing Touches: Specify any secondary operations such as finishing details, heat treatments, anodizing, or plating to ensure your parts meet the highest standards.

Compliance and Certifications: Let us know about any critical industry standards or customer specifications you adhere to, including First Article Inspection, PPAP requirements, and necessary certifications.

Additional Insights: Any target pricing, desired lead times, or other pertinent information will help us align our services with your expectations.

As a company established in 2006, we deeply understand the importance of integrity, and protecting the privacy of our customers is something we take extremely seriously. We can sign a NDA(non-disclosure agreements) before receiving your drawings, so please feel free to leave your design to us!

That’s not a problem. Just send us the photos of each angle, tell us the overall dimesions, material, surface treatment and QTY of the sample, and we will quote an approximate price. If you think the price is right, we then make samples based on the drawings we get and adjust them to perfection.

Empowering Smart Manufacturing for Electronic Components: From design to manufacturing, we provide diverse material options, including aluminum alloy, steel, titanium alloy, and plastics, helping your electronic components achieve a leap in performance.

The electronics industry is the core engine of technological innovation, and precision manufacturing is the key to driving its development. From semiconductor chips to precision components, every advancement requires the highest quality materials, processes, and equipment. Baichuan excels in providing custom-engineered solutions, tailoring our advanced CNC machining and welding capabilities to meet the unique and demanding specifications of the electronics industry

Baichuan Precision accepts 2D drawings (.DWG, .DXF) and 3D models (.STEP, .IGES, .X_T) formats; our engineers are available 24/7 to provide drawing optimization services and timely feedback. You can also send samples for us to work from

Baichuan Precision has accumulated a vast industry database and a wealth of case studies, giving us extensive industry experience. Our welding team is spearheaded by an expert boasting over 40 years of experience in the field.

We boast a complete industry chain service, equipped with a Class 1000 cleanroom and a variety of advanced testing equipment, ensuring that our products meet the highest standards at every stage.

We have established trusted partnerships with customers across various industries. With a reliable global supply chain, we always prioritize confidentiality, ensuring the security of your project information.

We provide mission-critical components to global innovators in a variety of industries, including aerospace and the semiconductor industry.

Our 24/7 engineering team ensures that you’re on track from prototype to production – that’s why 100 + companies rely on our responsive manufacturing ecosystem.

We offer customized solutions from medical-grade components to large semiconductor vacuum chambers with max precision (±0.005 mm).

We deliver precision 3D-printed prototypes in metals/plastics with 24-hour quoting and for complex geometries that CNC can’t handle.

A professional welding team led by more than 30 years of senior welding engineers with US semiconductor certification.

We can render assistance in foreseeing potential design issues, creating prototypes, and producing injection molds to lower the costs that have been ballooning for you in recent years.

Embracing a culture of quality excellence, our company is certified to ISO 9001:2015, demonstrating our commitment to customer satisfaction and our capability to consistently deliver high-quality products and services. To ensure precise validation of part conformity, we adhere strictly to drawing specifications and employ a comprehensive suite of precision metrology equipment, including Coordinate Measuring Machines (CMMs), for full-dimensional inspection. Detailed inspection reports are provided, guaranteeing that every delivery meets our clients’ stringent requirements.

This is an electrochemical process that enhances the corrosion resistance, wear resistance, and insulation of metals by forming a corrosion-resistant oxide layer on the metal surface, and can also be dyed to obtain different colors and appearances.

Polishing is a process of reducing the surface roughness of a material by mechanical, chemical, or electrochemical methods to obtain a smooth surface, aiming to improve finish, remove surface defects, improve appearance, and reduce friction.

Sandblasting is a surface treatment technique that cleans, deburrs, etches, or changes the surface roughness of a material by blasting abrasive materials onto the surface at high speed, and can remove surface oxide scale, rust, oil stains, etc., and change the roughness of the surface to increase friction or adhesion.

Uses electrochemical methods to deposit a metal coating on the metal surface to improve corrosion resistance, wear resistance, or appearance. Electroplating is widely used in the electronics industry to improve conductivity and prevent corrosion. Common electroplating materials include gold, silver, nickel, chromium, copper, and zinc.

Normally, we will provide a quote within 12 hours. If the information you provide is comprehensive, it will allow us to quote you faster.

As an ISO-9001 certified factory, we will strictly follow the tolerance requirements on your drawings. We can provide relevant reliability test reports. For example, High Temperature High Humidity Reverse Bias (H3TRB) test, Temperature Cycling (TC) test, etc.

Yes, our company has a team of specialized application engineers who can provide support in various areas. Our engineers have extensive machining and manufacturing experience, understand the complexities of design, and are prepared to reverse engineer projects. They are committed to supporting your project throughout the process and bringing your vision to life. We also offer a bespoke service where expert engineers with 40 years’ experience will provide one-to-one quotes and customization to your needs.

CAD Files in Any Format: Whether it’s 2D or 3D, we accept STP, IGES, X_T, DWG, PDF, STL, ensuring no design is too complex for us to handle.

Project Specifics: Share your expected quantities, desired machining processes, and material requirements to help us tailor our services perfectly to your needs.

Finishing Touches: Specify any secondary operations such as finishing details, heat treatments, anodizing, or plating to ensure your parts meet the highest standards.

Compliance and Certifications: Let us know about any critical industry standards or customer specifications you adhere to, including First Article Inspection, PPAP requirements, and necessary certifications.

Additional Insights: Any target pricing, desired lead times, or other pertinent information will help us align our services with your expectations.

As a company established in 2006, we deeply understand the importance of integrity, and protecting the privacy of our customers is something we take extremely seriously. We can sign a NDA(non-disclosure agreements) before receiving your drawings, so please feel free to leave your design to us!

That’s not a problem. Just send us the photos of each angle, tell us the overall dimesions, material, surface treatment and QTY of the sample, and we will quote an approximate price. If you think the price is right, we then make samples based on the drawings we get and adjust them to perfection.

Kunshan Baichuan Precision Components Co., Ltd

Address: Building 1, No.525 Maoxu Road, Kunshan 215312, Jiangsu, P.R. China

Email: sales92@partstailor.com

Phone: +86-18551199566

Kunshan Baichuan Precision Components Co., Ltd

Address: Building 1, No.525 Maoxu Road, Kunshan 215312, Jiangsu, P.R. China

Email: sales92@partstailor.com

Phone: +86-18551199566

Subscribe to receive our latest news and innovations directly in your inbox.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.