Stability, feasibility and economy

1. It is the first to measure and evaluate the Longmen Machining Center from the three aspects of stability, feasibility and economy. Taiwan's gantry machining center production is at least 10 years earlier than China's or even longer. Therefore, the stability and reliability of the product have been gradually improved and improved. At the same time, the price is relatively cheap. Facts have proved that Beijing Aqi used the Yawei Longmen machining center to process the EDM machine bed. After 10 years of use, users report that it still maintains the factory precision. However, in addition to the three aspects of Beiyi, Jier, and Wuzhong, domestically produced brands have basically been developed and produced in recent years, and there are not enough facts to prove that they can achieve the above three aspects.

Technically

2. For heavy cutting, from the perspective of skills, Western European products should be selected, combining skills with price.

Large-scale automobile sheet metal such as plastic molds

3. It can be used for plastic molds and other large-scale automobile sheet metal, including the four major brands of Yawei, Qiaoweijin, Qiaofu and Xiehong in Taiwan Province. Every year, the above manufacturers have hundreds of units for domestic choice.

Surface finish processing of large molds and other large products

4. Suitable for surface finish processing of large molds and other large products. Japanese brands have obvious advantages. The main products are Dai, Toshiba's new Nihon Koki. Among them, the first two are machine tools for manufacturing machine tools or high-precision mold processing, and the latter is used to process high-end molds and large box structure parts.

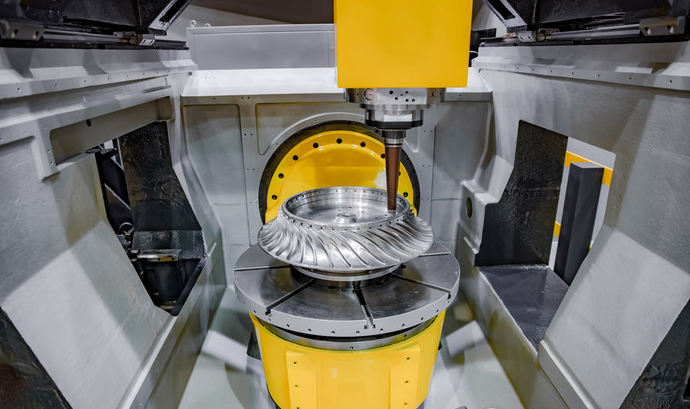

Five-axis high-speed gantry machining center

5. The five-axis high-speed gantry machining center generally does not export due to the technical F locks of the United States and Japan to China, especially for military enterprises. In our country, it is mostly Germany, Italy, and Spain. Low-priced high-speed five-axis gantry suitable for heavy cutting. First of all, Spanish products were selected. Taiwanese high-speed five-axis gantry machining center also entered the mainland.

Lightweight material processing

6. The lightweight material processing gantry machining center is a good choice for Z. It is generally used for model processing such as automobiles. It has the characteristics of five-axis high-speed and large-scale specifications. The price is also around 500,000 euros.

Advantages of domestic gantry

In terms of domestic gantry machining centers, there have been many manufacturers in recent years. Some have cooperated with foreign joint ventures to introduce technology, and some have purchased functional components such as spindles from abroad, and are equipped with gantry, workbench and bedspreads. Most of them are In the development stage, there is of course still a gap in maturity compared with foreign countries. But domestic machine tools always have to have this process, plus the price is cheaper.

Kunshan Baichuan Precision Components Co., Ltd. is a company specializing in CNC machining, precision parts machining, gantry milling, CNC precision machining, CNC numerical control machining. The company is equipped with CNC machining centers, large gantry machining centers, three coordinate measuring machines and other high-precision Equipment, support product customization and small batch production.