Photo by Engin Akyurt on Pexels

1. Introduction

The workpiece is shaped and enlarged to the required dimensions using machine tools, which are commonly powered metal cutting or metal farming tools. Numerous machinist tools catalogs are available for use in every machining job. A perfect tool can only deliver the best productivity and effectiveness. One benefit of being a machinist is having exposure to various tasks. But distinct tasks call for various equipment. Knowing the list of machine shop tools that are best for each sort of project is therefore necessary.

The crucial machine toolbox you have to have for your projects is described in this article. We will describe it into three essential groups to make it simple to find. Each group includes tools that are crucial and pertinent. Read this article, pick up a good machine toolbox, and stay within your spending limit. Let's start with the inventory of tools for the machine shop.

2. What are Essential Machining Tools?

The term "essential machining tools" refers to the fundamental equipment required for metalworking activities including cutting, drilling, milling, and turning. Most machining technicians concur that a core collection of tools is necessary for finishing the majority of projects. Here is the list of machinist tools catalog.

- Tools for accuracy measurement.

- Equipment for manual process.

- Power Cutting Equipment.

3. Tools for Accuracy Measurement

The accuracy measurement depends on the type of data being analyzed and the precise objectives of the analysis that determine which techniques can be utilized for accuracy measurement. Listed below is a list of machine tools that can be used for accurate measurement:

● Thread gauge:

To measure the pitch or size of a screw or bolt thread, a thread gauge is employed. A tiny, portable tool with various blades or pins of various lengths and shapes is the common form element.

In the manufacturing, mechanical engineering, and metalworking sectors, thread gauges are frequently employed because accurate thread measures are crucial for assuring the performance and security of mechanical systems.

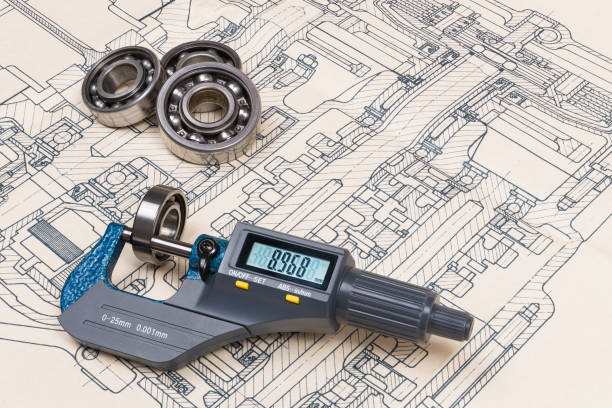

● Micrometer:

A micrometer is a highly accurate measuring tool with an accuracy of one-thousandth of an inch. This tool is frequently used in machining processes and is necessary for precise measurements. It is also known as a micrometer screw gauge and is often used to accurately measure an object's diameter, thickness, and length.

● Height gauge:

A height gauge is a precise measuring device that is employed to measure the height or vertical distance between a reference surface and the object being measured. It is also referred to as a height measurement tool or height micrometer. It is made comprised of a base that stabilizes and supports the instrument, a measuring scale or vernier, and a vertical beam.

The height gauge is frequently used to measure the height of various items, including machine parts, electronic components, and other products, in manufacturing, machining, and quality control applications. In order to provide precise and accurate readings, it is frequently used in conjunction with other measuring tools like calipers and micrometers.

Height gauges come in various layouts, including mechanical, digital, and dial height gauges. While digital height gauges employ electronic sensors and displays to deliver precise readings, mechanical height gauges use a vernier scale to interpret the measurement. Dial height gauges read the height measurement using a dial gauge mechanism.

● Caliper:

Caliper is a tool for measuring the gap between two opposing surfaces of an object. A sliding mechanism is often used to move the two parallel jaws or legs away or together. Calipers are frequently used to precisely measure an object's dimensions in industries like engineering, machining, and carpentry.

There are various different kinds of calipers available, each with its own benefits and uses, such as digital calipers, vernier calipers, and dial calipers. Vernier calipers have a scale and a sliding vernier which can be utilized to make accurate measurements, whereas digital calipers have an electronic display that shows a highly accurate reading.

Photo by Tima Miroshnichenko

● Surface plate:

A granite surface plate or another material with comparable stability and resistance to temperature changes can be used as a surface since it is smooth and level. When measuring different items and materials for manufacturing, machining, and other precise engineering applications, it serves as a reference surface.

Surface plates are frequently employed with measuring apparatuses including height gauges, dial indicators, and coordinate measuring machines. Measurements conducted on the surface plate are reliable and repeatable due to their flatness and stability.

Depending on the application, surface plates are available in a range of sizes and degrees of precision. Black granite is frequently used to make the most exact surface plates, and these plates typically have a lapped finish, which denotes that the surface has been flattened out by grinding and polishing to a great degree.

To keep surface plates accurate, they must be properly maintained and cared for. They should be safeguarded from harm and freezing conditions, kept clean and free of debris, and kept out of the way. Surface plates can be kept within their designated tolerance limits by routine calibration and inspection.

4. Power Cutting Equipment.

Equipment used to cut through numerous materials, including metal, wood, concrete, and more, is referred to as power-cutting equipment. Electricity is utilized in power-cutting equipment to supply the energy required to cut through materials. Electric saws, electric drills, plasma cutters, and laser cutters are a few examples of electrically powered cutting tools. The following are a few examples of typical power-cutting equipment list:

● Water jet cutter

A water jet cutter is a very accurate cutting device that can pierce a variety of materials by firing a high-pressure jet of water that is occasionally combined with an abrasive substance. In order to create a narrow stream of water, the technique entails pressurizing water to extremely high pressure. This pressure is normally between 30,000 and 90,000 pounds per square inch (PSI).

The water stream is so strong that it can precisely and accurately cut through materials including metal, stone, glass, and composites. To increase the water's ability to cut, abrasive particles like garnet are occasionally added to the water stream.

Engineering, manufacturing, automotive, aerospace, and other industries can all benefit from the versatility of water jet cutting. It is especially helpful for cutting heat-sensitive materials like plastics and foams as well as materials like ceramics and composites that are challenging to process using conventional cutting techniques.

Water jet cutting has a number of benefits, one of which is the absence of a heat-affected zone, which prevents deformation or damage from the heat on the material being cut. Water jet cutting also doesn't emit any harmful gases or waste materials, making it a non-toxic and eco-friendly technique.

● Angle grinder

A portable power tool called an angle grinder is frequently used to cut, grind, and polish materials like metal, stone, and concrete. It is made up of a spinning cutting wheel or abrasive disc mounted on a spindle, a motor, and a gear reduction system.

Angle grinders come in various sizes, from diminutive 4-inch units to substantial 9-inch variants. Although certain versions may employ gasoline engines, they are typically propelled by electricity or compressed air. Depending on the task at hand, the disc or wheel used with an angle grinder can be changed, and there are several types of discs that can be used for different applications.

Due to their adaptability and power, angle grinders are frequently employed in the construction, metalworking, and fabricating industries. But if not used correctly, they can also be harmful, so it's crucial to abide by safety precautions like maintaining the required personal protection equipment and making sure the instrument is grounded properly.

Photo by Tima Miroshnichenko on pixels

● Jigsaw

A jigsaw is a small, portable power tool used for cutting curves and complex shapes in a variety of materials, including ceramics, metal, wood, and plastic. To cut through the material, the tool employs a reciprocating blade that oscillates up and down. Jigsaws are frequently used in woodworking and construction for activities like making delicate cuts in decorative trim and sink holes in countertops and door frames.

Jigsaws are adaptable and can shave through a range of materials with varying densities and thicknesses. They come with several blade types that are made to cut different kinds of materials. Some jigsaws allow you to alter the cutting speed to match the material you are working with through customizable speed settings.

5. Equipment for Manual Process.

Equipment that is operated or controlled manually—without the use of electricity or other external power sources—is referred to as manual equipment. They are frequently used in a variety of tasks, from building and carpentry to gardening and auto maintenance, and are normally made to be handled and operated by hand. Several instances of manual machinery set include:

● Hand tools

These are hand-held tools that can be used for machining purposes or handling workpieces. Here are a few instances of typical hand tool sets:

- Hammers are tools for hitting and pounding items like nails or other objects into materials like wood.

- Screwdrivers are tools for tightening or loosening screws or bolts.

- Pliers: These are used for grasping, bending, and cutting wires or other materials.

- Wrenches: To tighten or loosen nuts and bolts.

- Saws are tools used to cut wood and other materials.

- Chisels are tools for cutting and forming stone, metal, or wood.

Photo by Louis Hansel on Unsplash

● Cutting tools

Tools for cutting or shaping various materials, including metal, wood, plastic, and many others, are known as cutting tools. In order to endure the heat and friction produced during cutting, they are often made of strong materials like high-speed steel, carbide, or ceramic.

Cutting tools come in a variety of common forms, such as

Saw: A device with a blade used to sever materials like plastic, metal, or wood.

Drill: A device that uses a revolving bit to make holes in materials.

A lathe is a device that shapes a workpiece by rotating it as a cutting tool travels along it.

A milling machine is a device that removes material from a workpiece using revolving cutters.

● Measuring Tool

Equipment or device used to quantify or evaluate an object's size, distance, weight, volume, or any other physical characteristic is known as a measuring tool. The type of measurement to be made, the level of accuracy needed, and the range of values to be measured all influence the measuring instrument selection.

Rulers, tape measures, calipers, micrometers, scales, thermometers, hygrometers, and barometers are a few typical types of measuring instruments. Optoscopes, spectrometers, and force gauges are some other specialized measurement devices.

● Safety equipment

Any tool or system created to shield users from risks or injuries is referred to as safety equipment. Personal protective equipment (PPE) including safety goggles, gloves, respirators, machine safety guards, and first aid and fire extinguisher kits are a few examples.

● Cleaning tools

Various cleaning tasks can be accomplished using a variety of cleaning equipment types. Here are a few instances:

- Dusting and cleaning surfaces are done using microfiber cloths.

- Window squeegees are tools for washing windows and wiping away water stains.

- Vacuum cleaners are used to get rid of dust and debris from floors and equipment.

- Sponges are tools for cleaning surfaces.

- Brooms are tools for sweeping up dirt and debris from floors.

Conclusion

Having the appropriate machining toolbox is crucial for any machinist. The list of essential machining tools for any machinist's workshop is exhaustive and may be found above. With the help of this machining tool, you'll be able to manage a variety of machining operations and produce precise and accurate outcomes. This blog was helpful for you? Just let us know by commenting below.