A computer-controlled machine is used to cut and shape materials during the automated manufacturing process known as CNC machining. It is frequently utilized in the fabrication of medical devices, automobiles, and aerospace products. The feed rate and cutting speed are two crucial variables that affect the process quality and effectiveness in CNC machining. Although these two words are frequently used interchangeably, they actually have different connotations and purposes.

The machine's effectiveness is mostly due to the CNC-controlled relative motion of the tool and workpiece. Both cutting and feeding motions can be employed to quantify its actions. But, how is feed rate different from cutting speed? In addition, how do these machining variables impact the results of your manufactured workpiece? This article provides answers to each of these questions. So let's get started.

1. Why are Feed Rate and Cutting Speed Significant?

The material removal rate—the quantity of material removed per unit of time—is determined by the interaction of these two variables.

The softer the material is, the faster it can be cut. As the material of the cutting tool becomes stronger, the cutting speed likewise increases. Cutting forces and built-up edge (BUE) propensity in face milling are influenced by cutting speed and feed rate.

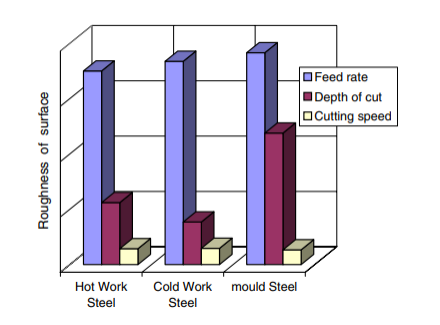

The key regulating factors in metal cutting are depth of cut, feed rate, and cutting speed. The interaction of the cutting tool and workpiece, cutting forces, and surface quality are all closely related.

Speed and feed are important factors in the production of machined parts because they regulate how much and how quickly material is removed. The speeds and feeds may significantly affect how long a tool lasts.

A slight mismatch between the feed rate and speed will cause the cutting tool to shatter right away. Speeds and feeds are critical for achieving better surface roughness. Whenever the machine is running at a high spindle speed and tool rate, chattering marks will develop on the substrate surface.

2. Difference Between Feed Rate and Cutting Speed

Although the machine's total performance would be impacted by both the feed rate and cutting speed, these terms ultimately indicate two distinct aspects. It's critical to comprehend the distinction between the two so as to maximize the performance of your CNC machine. Here are some differences

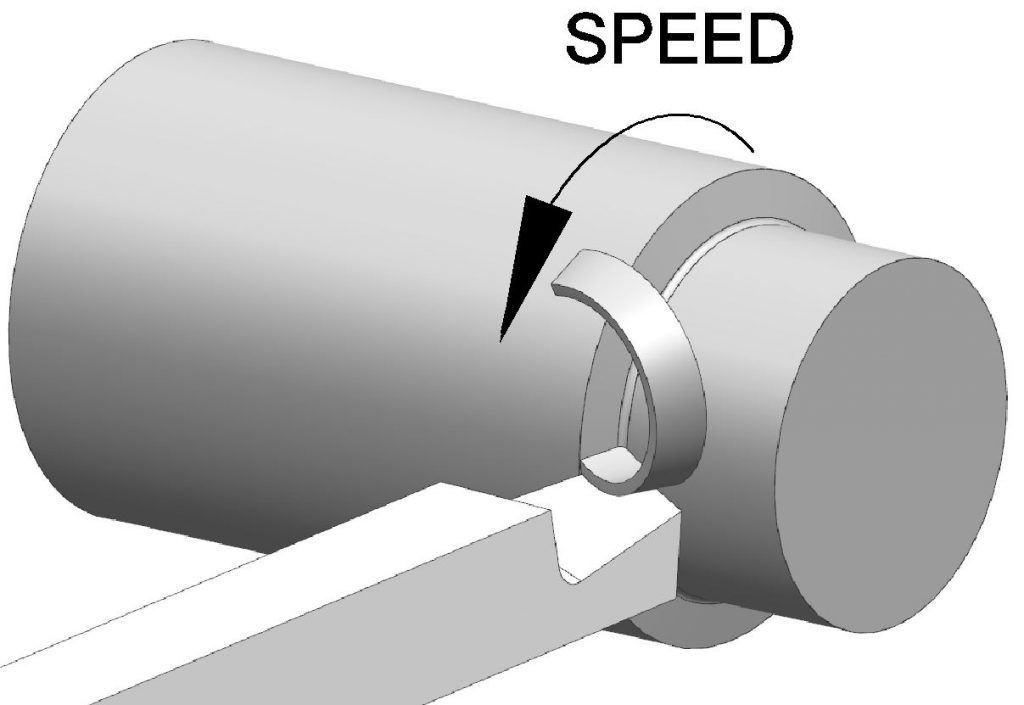

- The primary distinction between feed rate and cutting speed is that the earlier refers to the pace with which the tool rotates across the workpiece, while the latter refers to the movement of the tool's cutting edge.

- The horizontal distance that the cutting tool covers on the workpiece surface in a minute is referred to as the feed rate. Cutting speed is the rate of rotation, measured in revolutions per minute (RPM), of the cutting instrument. In comparison to the feed rate, which is inversely proportional to the number of cutting edges, cutting speed and tool diameter are directly proportional.

- On the other side, feed rate describes how quickly the cutting tool enters the workpiece. The speed of an object is normally expressed as a distance in inches per minute (IPM) or millimeters per minute (mm/min), depending on whether it is a rotating instrument or an oscillating one. The depth, width, and preferred rate of material removal all influence the feed rate.

- Cutting temperature is an important component that can affect metrics like tool life and surface roughness, which may clarify why there is a disparity between feed rate and cutting speed.

- The cutting speed, usually expressed in m/min or ft/min and indicated by Vc, yields a generatrix. The feed rate, usually expressed as mm/rev or mm/min and marked by s or f, produces a directrix.

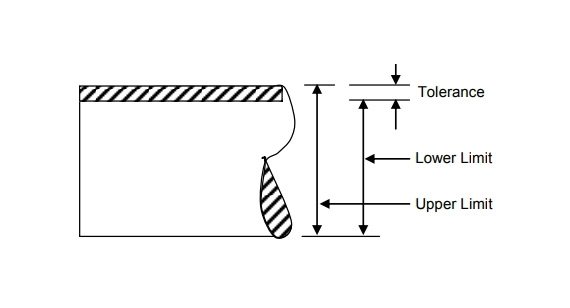

- The formation of scallops or feed marks on the surface that is machined is not directly related to cutting speed. Although the feed rate will directly affect the scallop marks on the machined product's surface, which will directly reflect the degree of surface roughness.

Effect of cutting parameters onto Ra for various workpiece materials

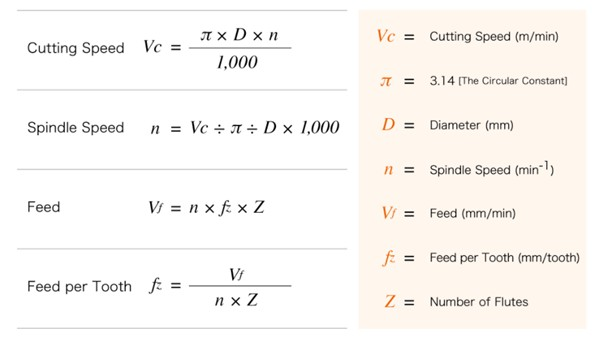

3. How to Calculate the Feed Rate and Cutting Speed?

All the variables required to calculate the cutting speed and feed rate are shown in the below graphic. The essential prerequisite for determining cutting speed and feed is spindle speed. The ultimate feed can be obtained using two different techniques: first, by figuring out the feed per tooth, and second, by figuring out the feed of the tool using this feed per tooth.

In machining operations, feed rate and cutting speed are two crucial variables that require careful consideration. You can assess these metrics using the steps below:

- Material Properties: The type of material being machined will determine the feed rate and cutting speed needed. Determine the qualities (characteristics such as heat conductivity, toughness, and hardness) of the material you are processing.

- Tool characteristics: The feed rate and cutting speed will also be impacted by the type of tooling you are using, such as high-speed steel or carbide. Ensure that you are aware of the potential and constraints of your equipment.

- Consult the machining data: There are several sources that include the required feed rates and cutting speeds for various types of tools and materials. To acquire a rough idea of the ideal parameters, consult these references.

- Run trials: Conduct tests with various feed rates and cutting speeds to identify the best settings for your particular setup. To determine the highest numbers that still yield usable results, start with cautious values and gradually increase them.

- During the trial runs, pay close attention to the machining process to make sure that the feed rate and cutting speed are yielding the intended results. Watch for indications of tool wear or other problems that could mean the parameters need to be changed.

- Modify the specifications: After figuring out the ideal feed rate and cutting speed, further fine-tune them by implementing minor changes to the machining procedure to suit your particular setup.

4. Choosing the Best Feed Rate

The feed rate has a direct impact on every aspect of CNC machining, including safety, productivity, tool life, and product quality. The material being machined, the kind of cutting tool being used, the machine being utilized, and the goal of the machining operation all play a part in determining the appropriate feed rate.

Most of the time either CNC machine operators or programmers subjectively select the feed rate. As a consequence, the feed rate is fixed at a conservative value, which results in longer machining times or lower tool life because it is not optimal in terms of the cutting parameters at each cutter spot. To help you choose a feed rate, keep in mind the following general recommendations:

Feeding rate limit

Only a few feed rate options within the range are available for the standard lathe machine tools, however going over the limit is not permitted for these types of machine tools.

Productivity

Losing surface quality will increase the feed rate for higher productivity rates. In another instance, the cutting speed can be raised by keeping the feed rate constant.

Surface Quality

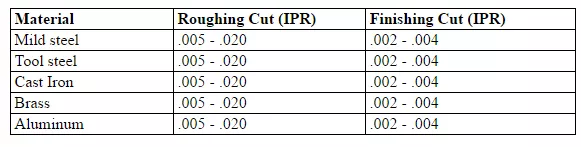

Lower feed rates can result in better surface polish. For the rough cut, a coarse feed rate may be taken into account. For instance, the feed rate could be 0.1-0.3mm/rev for rough turning and 0.01-0.05mm/rev for finishing operations.

Cutting tool Mechanics

In addition to the feed rate, the tool shape can have an impact on the products' surface polish. When the design allows, a greater value for the dimensions of the tool can be selected.

Minimizing the amount of time needed to accomplish a task while keeping the appropriate degree of accuracy and surface polish, feed rate, and cutting speed optimization can increase the efficiency of machining operations.

5. Choosing the Optimal Cutting Speed

The ideal cutting speed must be ensured in order to acquire the greatest results from the CNC machining procedure. As feed rate and cut depth increased, cutting forces also increased. Measurements of the surface's roughness revealed that as the cutting speed was increased, roughness values decreased. The following parameters can be used to forecast the ideal cutting speed for a specific CNC machining technique.

The Cutting Device's Capacity

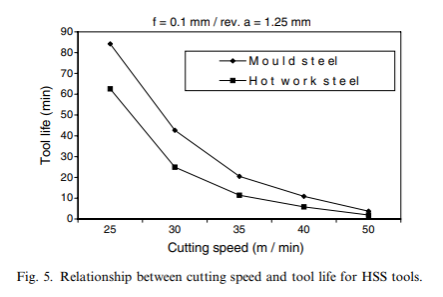

The strength of the tool's cutting edge is a key factor in determining the maximum cutting speeds for machining operations. For instance, high-strength materials such as diamond and carbon boron nitride are able to be utilized to make cutting tools for machining that can achieve greater cutting speeds. However, The cutting tools constructed from high-speed steel could be utilized for slower cutting speeds.

Cutting Tool Material

The ideal cutting speed is also influenced by the substance of the cutting tool. For instance, tools made of carbide are capable of faster cutting speeds than those made of high-speed steel.

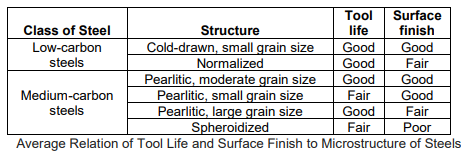

Harder workpieces require special attention during the machining process because they may rapidly decrease tool performance. A tougher material requires slower cutting speeds when being machined. For instance, compared to steel, titanium requires a lower cutting speed.

Surface finish specifications

Lower cutting speeds could be essential to avoid tool scratches and other surface flaws if a high-quality finish is required.

Tools' life

The tool life is impacted and depends upon the type of tool material. The softer

cutting tool materials cause quick deterioration at higher cutting speeds, and tool life will be reduced. How long the engineer or machinist intends to work on that tool is an additional important aspect of deciding on cutting speed.

For the most part, this will take into account factors like the price of the tool and the number of pieces produced. The fast cutting speed may be used provided that these parameters stay within the permitted ranges. Cutting depth (a) is the characteristic that has the least impact on tool life, whereas cutting speed (V) and feed rate (f) are the two that do the most.

What Speed and Feed Should I Use?

The formula below can be employed for calculating spindle speed for transforming various materials provided the SFM constant is known for a particular material.

RPM = SFM x (12/Pi) / Cut Diameter

The speed or velocity of the spindle is directly related to the revolutions per minute (RPM). It indicates how many rotations around a fixed axis were performed in a minute. Through every step, the RPM keeps the same revolutions per minute.

Most CNC lathes use CSS (constant surface speed) to avoid the spindle from gradually reducing speed as the tool gets closer to the turning axis. CSS changes the revolutions per minute so as to preserve a consistent surface speed at any inclination from the center.

Inches Per Minute (IPM) or Inches Per Revolution are two ways to quantify feed rate. (IPR).

The following formula makes it simple to determine IPR's value:

IPR=IPM / RPM

Aluminum may be cut at rates of 400–700 with high-speed tools and 800-1000 with carbide tools, respectively. With a high-speed tool, the feed per revolution for aluminum is roughly between.003 and.030 inches, and between.008 and.045 inches with a carbide tool.

The type of tool, cutting method, machine capabilities, and desired finish can all have a significant impact on speed and feed. Operations like threading or splitting off require substantially slower rates, usually 1/3 to 1/4 of the anticipated RPM.

The feed rate for different materials

Conclusion

In order to maximize the various CNC machining characteristics, including tool life, power consumption, time, roughness, speeds, and feeds must be used. The manufacturing of CNC machined parts greatly benefits from the interaction of cutting speed and feed rate. Therefore, engineers and machinists must fully comprehend them before deciding on the speeds and feeds.

Increases in feed rate and cutting depth have a negative impact on surface quality. The surface quality improves as cutting speed increases, however, this effect seems to be minimal. Did this blog was helpful for you? Just let us know by commenting below.