What is 5-axis CNC Machining?

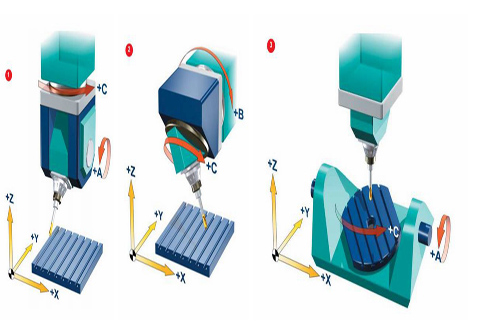

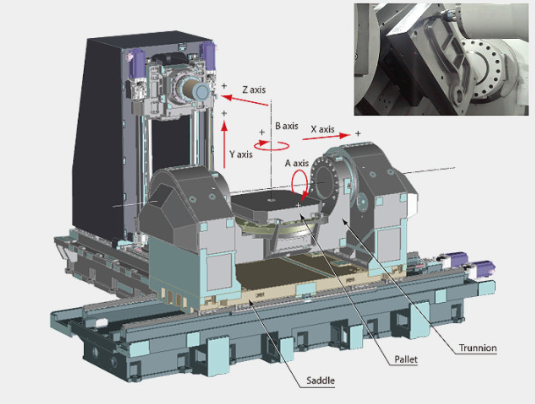

5 axis machines are the most advanced form of the Computer Numerical Control machines. These Machines enable the workpiece to be manipulated from multiple axes, Beside the three regular axes that are X, Y, and Z used in 3 axes CNC machines, these 5 axis machines are able to move the substrate to the additional fourth and fifth axis, which is achieved by the rotation of the spindle. These axes are often known as A, B, and C axes.

For example, in normal 3+2 axis, 3 axis 0r 4+1 axis’s machines one needs to perform many complex operations, and a full type operator is required for those machines, which results in excessive time, poor surface finishing, 5 axis’s machines solve this issue by giving the machinist extra two rotatory axes to perform all type of complex operations in less time with improving machining results.

One firstly has to decide which Machining services he would need for its Machining purposes. For consultation and blueprints of the product, an expert consultation must be required, luckily at www.bccncmilling.com, you are able to get the free consultation and product Mockups from Expert Engineers and machinists.

How To Set up a 5 Axis machine:

Configurations of 5-Axis Machining:

Depending upon the Work Load and Design of the products Machines are set up in variant ways regarding their axes, Parts to be Machined and Surface finishing needs, Two Main adjustments are as below.

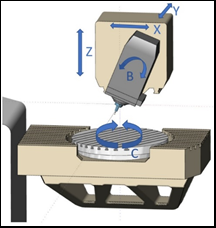

Swivel-Rotate-Style:

These Machines use a rotation of spindle for rotating axes machining, this setup is best for Machining heavy parts as the table is constantly horizontal in this case.

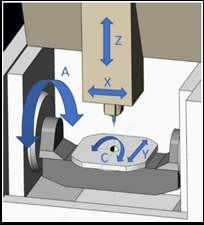

Trunnion-Style:

Turnin-style machines are used where we need to Machine Large volume arts, thanks to their moving table technology, which is ideal as no space is being occupied by the Spindle.

The working axes and their directions are as follows

- X-axis – left to right

- Y-axis – front to back

- Z-axis – up and down

- The A axis can rotate 180° around the X-axis

- The B axis can 180° rotation around the Y-axis

- The C axis can 180° rotation around the Z-axis

Programming and Specifications:

As the 5 axis CNC machining comes up with the most advanced machining option from the 5 different axes, that can only be achieved from the advanced CNC programming software, this advanced CAD-CAM Programming software comes up with advanced programming and anti-collision options that able the programmer to customize it in countless ways.

Due to these advanced features, these machines can be operable for long hours without any specific check. All the five axes were programmed as per the drawing and the machine is capable to perform the rest machining operations and cutting through the CNC controller.

Why You Should Choose 5-Axis CNC Machining:

5 Axis’s Machining is far better than regular 3 axes, 3+2 axis, or 3D printing, if you are looking for efficiency and durability specifically for the complex and highly precise parts.5 axes Machining ables the operator to get its desired results within the minimum time with high accuracy.

5-axis vs. 3D printing:

The Core difference between these two manufacturing techniques is their operational Techniques, 3-D printing which is quite popular these days is basically an additive manufacturing technique. While the 5 Axis’s machining technology belongs to subtractive manufacturing. one can use 3D printing for certain parts and domains. But for manufacturing highly precise and complex designs, 5 axes machines have no match.

5-axis vs. 3+2 axis:

Differentiating Between 3+2 axis machines and 5 axis’s machines is a little bit tricky, As most people thought 3+2 Axis machines as 5 axes, but they are actually 5 axis’s index machines, They need starting or stopping requirements during the manufacturing, while 5 Axis machines can produce same parts in Less time and high finishing without any assistance.

How much does 5-axis CNC machining cost?

Price breakdown for CNC machining services:

Most CNC machining services are Rated as per their expertise, Advance Machinery certifications, Previous project records, and expert Operators. The more the expertise a machining workshop has the more the price and quality it will offer.

For example, CNC turning is typically cheaper than multi axis’s machining options that are due to the material, expertise, and the high trained operator needed for high axis machines. The total cost of a client’s service is, therefore, contingent upon project specifics.

To understand the pricing budget for CNC machining you should consider these below-mentioned factors.

The Materials

The type of material and the machining properties are the known factor that, Affect the overall cost of the product. The two main factors are

- Raw material availability and its price

- Material machining cost.

Some materials are less expensive to purchase, but due to properties like ductility and tensile strength, they are extremely difficult to manufacture. For example, aluminum is more ductile, while high carbon steel is slightly less so.

For example, in steel and aluminum, the steel is more durable but it is a little bit more costly as compared to aluminum, However, steel can more machining operations and fatigue. The materials which are mostly used are

- Steel

- Brass

- Copper

- Cast iron

- Aluminum and much more as per your desired conditions.

Order Quantity

The total cost is influenced by the number of components to be machined, as bulk orders lower the per-unit cost for the consumer. Because it shortens the time frame and lowers the cost of materials for bulk purchases.

The Geometry :

Component geometry and size is also a noticeable factor, as bigger size need more material to be machined and complex parts need a high-level programmer or even sometimes needs specific certifications after machining operations, which increase the overall cost in the end.

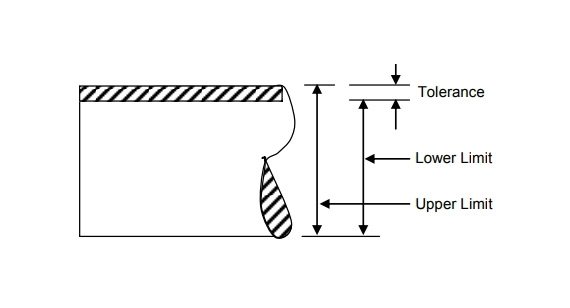

Tolerance Tightness

In CNC machining the shop that offers high tolerance means accuracy, the machine shop that offers high tolerance and precision means that they will provide the exact model of your drawing which ultimately depends upon years of skill and programming abilities, and they need top to be done from high professional operators and labor which increase your product ultimately. In simple more cautions or resources required, the higher will be the Price tag of your project.

Equipment Used

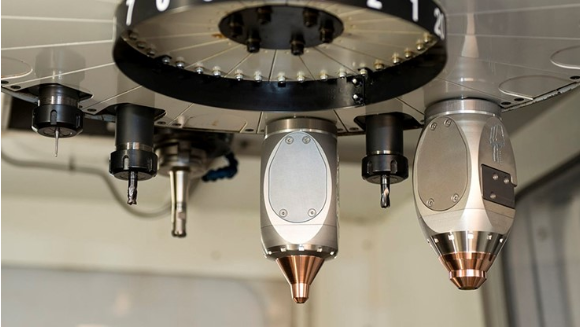

CNC machining equipment isn’t cheap, but a legitimate shop can't be operable without multiple machines. As some products need multiple operations and high axis machines are compulsory for them, these all factors have a clear impact on the price tag of machining services.

Machine Specifications:

- High tolerance and Precision.

- Machine Power and Speed of cutting.

- Spindle Power.

- Size of CNC Machine

Power:

Another key aspect of CNC machining costs is the machine's power, which is determined by the spindle RPM or torque it can produce. In addition, servo motors are a significant factor in heavy machinery.

For better understanding let us compare two CNC machines having specifications as mentioned, the stepper motor of a hobbyist Sainsmart Genmitsu runs at 0.18 ft-lb while that of a professional 6-axis CNC like the Zimmerman FZ100 can run at 68 ft-lb. That is due to the factor that 6 axis CNC machine servo motor is 400 times more power full than a hobbyist stepper Motor.

Axis:

The more degree of Freedom a machine has the more it is costly, that's why 5 Axis CNC machines are a little bit more costly than former 3 and 4-axis machines.

Considering 5 Axis’s machines they are further categorized as per price tag as

- 3+2 Axes Machines

- 4+1 Axes Machines

- FULL 5 Axes Machines

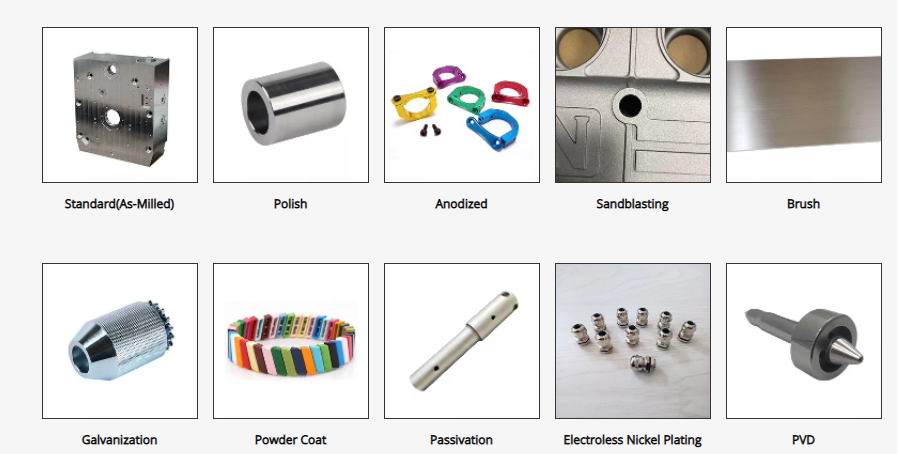

Finishing Processes

Surface finishing and after-machining processes will enhance your overall cost; some materials require treatment after machining for safety and durability, such as most medical and aerospace parts, and some surface finish techniques that may be used include.

- Anodizing

- Heat treating

- Polishing

- Specialty machining

- Painting

- Chroming

- Chrome sputtering

- Metallizing

- Silk-Screening

- Blacking

- Water transferring

It is not necessary to apply all the above-mentioned techniques, you should consult our experts at www,bccncmilling.com for a detailed discussion regarding your product blueprints.

Pros of 5-axis Machining

Complex machining:

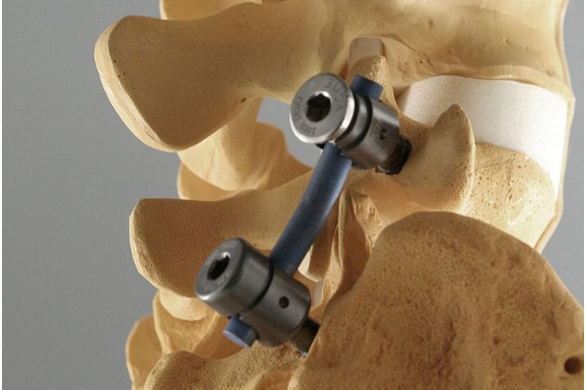

The 5-axis machines are most commonly used in industries that demand complex operations, parts, intricate design, and high tolerance, such as aerospace, medical, and oil, and gas industries.

Single Setup:

Multiple alignments are required for 3-axis machines, which increases prices, time duration, and error probability after machining operations. 5 axis machines, on the other hand, are single-setup devices that improve efficiency, decrease time, lower costs, and eliminate operational errors.

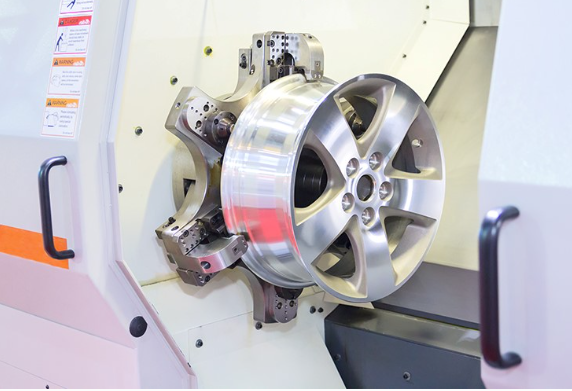

Automobiles, aerospace, medical, and other industries that require high productivity with short lead times can benefit from these machining alternatives. In a 3-axis machining setup, the program must be set up multiple times after each machining operation; however, this problem can be readily solved with 5-axis machines, resulting in great productivity with minimal lead time.

High Surface Finish:

The Parts produced by ordinary 3 axis or 3+2 axis machines need after machining or additive manufacturing operations for surface finishing. but in 5-axis machines despite regular 3 linear axes, the rotatory axis ables the machines to reach each part of the workpiece, and due to its high stability, it shows low vibrational effects, which results in a high surface finish.

Increased Productivity:

Because of their rotatable axis and contemporary programming techniques, the 5 axis machines are capable of performing complex machining tasks simultaneously. The operator only needs to put up the instructional programming commands once, and they will be executed as needed in the shortest time possible.

Cost Reduction:

Cost reduction is the most important aspect of 5 Axis’s Machines, due to increased productivity and elimination of the need for recalibration and reprogramming, which is done in 3 Axis’s machines, the mass production results in a noticeable cost reduction and in material wastage.

High Precision and Tolerance:

Moreover, these devices offer a high level of precision and tolerance, which is especially important in medical and military applications. The 5-axis capabilities and complicated programming result in a finished product that is exceptionally precise in terms of direction.

Cons of 5 Axis of Machining:

Cost is Too High

One disadvantage of installing 5-axis machines is the budget of installation; 5-axis machines are more expensive to install, and indeed the cost of machine tools and maintenance is also more than ordinary 3-axis machines.

Complex and Difficult Programming:

Advanced CAD-CAM programming is necessary for the operations of these five-axis machines, the rotating axis programming may damage the workpiece or machining tool if it is not done appropriately.

Furthermore, for appropriate Surface finishing and high precision, an expert programmer is required that enhances the overall cost.

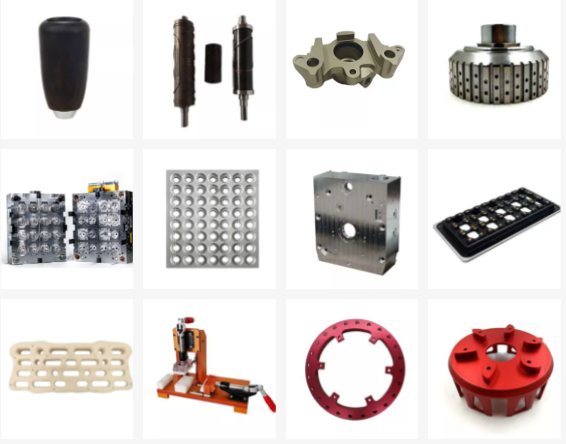

Applications of 5 axis Machines:

Aerospace:

The aerospace industry mostly needs those parts that are unique and geometrically interactive and demands a high level of detail. For this type of Drawing 5 axis machines are ideal, Moreover, they have the ability to make the whole part in one single pass with the highly precise results that are necessary for the Aerospace industry.

Medical:

Parts that require minute finishing and machining work are frequently required in the medical business. The 5-axis CNC machines can make parts for implants and other medical equipment that fulfill stringent healthcare standards.

Military:

Precision is something that is very ideal for Military equipment, military equipment specifically modern weapons need a lot of machining operations in submarine parts, turbine and compressor blades, high-performance engine parts, stealth applications, smart weapons, sensors, and even nuclear weaponry.

Some other industries where we can find applications of These CNC machines are

- Pharmaceutical

- Energy Sector

- Automobiles

- Shipbuilding and much more

Why Baichuan For CNC Machining Services?

Bai Chaun is a renowned CNC machining service provider having clients across the globe. We are the market leader in our category thanks to our advanced machinery and highly trained and skilled Engineers and programmers. We are currently providing all types of Machining services Including

- Reverse engineering

- Product Designing

- Product quotation and Drawings

- CNC prototyping

- Surface finishing

- Mold production and much more.

You can visit our website WWW.bccncmilling.com To check out our wide range of Product prototypes, you can also order free samples and product price quotation services from our experts.