Plastic injection(IM) molding was not commonly employed in CNC milling factory when the car industry first started. Metal was primarily used by automotive manufacturers to create parts. These metal parts were pricey and cumbersome. However, as the automobile sector expanded, so did the need for more productive and economical manufacturing techniques. As a result, automakers started experimenting with the creation of plastic car parts.

Injection molding was initially employed to create aesthetic components in the 1950s. Then, in the late 1970s and early 1980s, plastic injection molding quickly replaced other manufacturing techniques as the go-to method for creating molds for a variety of auto parts, such as dashboards, headlights, door panels, and instrument clusters.

The first plastic structural parts for automobiles were introduced by automakers in the early 2000s. These parts had the advantage of being lighter than their metal equivalents, which allowed for increased fuel economy and less expensive production. Injection molding is currently the most used production technique used in the automobile industry to make plastic car parts.

What are the benefits of using injection molding? What are the applications of injection molding in the automotive industry? We will discuss this all in detail in this blog. So, Let’s get started.

Photo by Ashley Deher on Unsplash

Why Injection Molding is a Preferred Method for Automotive Machining Company?

One of the most popular methods for producing plastics is injection molding. This is justified since it provides a workable option for the mass manufacture of high-quality injection-molded automobile components using a variety of polymers. Automotive plastic injection molding is a crucial production technique in the auto industry, where reliability, safety, and quality are of the utmost significance.

Additionally, manufacturers use injection molding as a highly adaptable technology to create a variety of vehicle parts, from engine elements to external body panels. Additionally, it is a flexible process that allows for bulk production of similar goods.

Injection molding is better than other manufacturing techniques in that it can produce products with intricate forms, precise tolerances, and high-quality surface finishes.

Plastic has gained popularity as a manufacturing material for automobiles for a number of reasons. Compared to some metals, plastic is more durable and stronger. Customers today also have new expectations for their cars, particularly in terms of comfort and fuel efficiency.

For automotive applications, injection-molded plastic components considerably exceed expectations set by metal components. Injection molding offers vital advantages in the automobile sector, where parts must adhere to strict safety, quality, and metric criteria.

Rapid tooling and quick prototypes

Injection molding can be utilized as a prototyping technique. Although, car manufacturers typically prefer it for large production. Rapid tooling allows injection molding producers to quickly and affordably produce molds, which automobile producers can utilize to produce small batches of prototype molded car parts considerably more quickly than with conventional prototype techniques.

One out of every five automobiles manufactured is exported, therefore quick prototyping and turnaround times are essential to the sector's success. The less time to market, the more competitive automakers are on the world market.

Materials Used to Create Automotive Injection Molded Products.

Automobile manufacturers have to adhere to strict safety regulations when designing and manufacturing their vehicles in order for them to be legally driven. For each plastic injection-molded automobile item, it is crucial to select the proper plastic and machining shop.

Since automobile manufacturers use automotive plastic injection molding to create a wide range of parts, not one material is appropriate for every purpose. As a result, many plastic polymers are utilized for automotive parts.

The list of typical automotive IM plastics and the components they are used as raw materials is not exhaustive, but it includes the following:

Plastic used in automotive parts manufacturirng

Poly Methyl Methacrylate (PMMA)

It is most frequently known as acrylic or PMMA. It is a robust, transparent thermoplastic that offers glass a more lightweight, impact-resistant alternative. A substantial amount of light may travel through PMMA because of its remarkable optical clarity and transparency.

Benefits and Drawbacks of Acrylics

Acrylics can be kept to precise tolerances during injection molding and have a high tensile strength to sustain weights. Thus, its machining is easy and useful for CNC milling industry. They also won't collect odours. The material is appropriate for outdoor use because it also resists sunshine and weather. PMMA won't release Bisphenol A (BPA), a chemical found in many plastics that has harmful effects on human health because it doesn't break down when in contact with water.

Applications

Acrylic is optically clear, strong, and transparent plastic. Making headlight covers and screens out of it serves as an alternative for glass.

Image by Hyundai Motor Group on Unsplash

Polycarbonate

Natural translucent materials with strength and durability are polycarbonate (PC) plastics. Their characteristics are comparable to those of PMMA. however, polycarbonate keeps its physical characteristics across a greater temperature range. PC that has been colored keeps its color and strength throughout time.

Polycarbonate's benefits

Additionally lightweight and with good optical qualities, PC material supports light transmission. This injection molding material offers perfect dimensional control due to its predictable and consistent mold shrinkage. 250 times stronger than glass, polycarbonate is very resilient.

Applications

Bumpers, defense screens, airplane panels, spectacle lenses, headlight lenses, helmets, and alternatives for bulletproof glass are just a few examples.

Polyamide (PA)

The name nylon 6.6 or nylon 6 refers to polyamide. It is versatile nylon that is moldable and extrudable. The mechanical and wear resistance of nylon 6/6 is good. They are typically employed whenever a low-cost, highly mechanically robust, rigid, and stable material is needed for machining industry. As a result, they cannot be used in applications requiring dimensional stability since they readily absorb water and expand when exposed to wet or humid conditions.

Benefits

Nylon PAs have a number of benefits, including great heat resistance and durability. Additionally, they have excellent fatigue resistance, high abrasion resistance, and noise-dampening qualities. Injected-molded nylon is excellent for high friction and wears applications due to its low coefficient of friction.

Applications

The main use of polyamide is in the production of components that go under the hood of engines, primarily employing fiberglass-reinforced polyamide (PA) varieties. Its applications include weatherproof coatings, gears, bushes, cams, and bearings.

Polyoxymethylene (POM)

Engineering plastic polyoxymethylene (POM), commonly referred to as acetal, is used in construction. It can be injection molded into components that need to be stiff, have a high coefficient of friction, and have great dimensional stability. POM polymers are opaque and white by nature due to their highly crystalline structure.

Benefits

POM that has been injection molded has a low coefficient of friction, great thermal stability, and excellent stiffness. Additionally, it resists chemicals well and absorbs little water. Homopolymers and copolymers are the two primary forms of POM plastics that are offered. As a result, acetal materials with various qualities are available to engineers and designers.

Applications

Bearings, gears, conveyor belts, and pulley wheels can all be made of POM. In addition, fasteners, lock systems, and high-performance technical components are being made.

Thermoplastic polyurethane (TPU)

This kind of thermoplastic elastomer (TPE), is frequently mentioned individually due to its widespread application. TPU shares a rubber-like elasticity with other TPEs; however, injection-molded TPU has a higher durometer and can be used as a substitute for hard rubber. Due to its superior chemical resistance and ability to withstand severe temperatures, TPU is frequently preferred over TPE. TPE, on the other hand, is more flexible and softer.

Benefits

TPU is more abrasion, chemical, grease, oil, and high temperature resistant than other TPEs. Injection molded thermoplastic polyurethane is ideal for usage in ozone-exposed environments and also has high load-bearing capabilities.

Applications

Polyurethane is widely used in items that need a high level of elasticity, such as foam seats. Car seats are one example. Additionally, PU is utilized to create insulating panels, suspension bushings, and seals and gaskets for automobiles.

Photo by Ildar Garifullin on Unsplash

Abutrene butadiene acrylate (ABS)

ABS is a thermoplastic of engineering grade that is simple to mold and has a relatively low melting point. This opaque polymer can be found in a variety of textures and surface treatments and supports the use of colorants. ABS is renowned for its durability and resistance to impacts and quite suitable for automotive machining industry.

Benefits

ABS withstands heat, oils, acids, and alkalis well and is durable and reasonably priced. The styrene gives injection-molded parts a bright, appealing surface, while butadiene gives it excellent resilience even at low temperatures.

Applications

Its typical uses include making dashboards and wheel coverings. The protective headgear, wall-mounted electrical outlet covers made of plastic, and pieces for cars.

Polypropylene (PP)

Similar to polyethylene (PE), polypropylene (PP) is slightly stronger and more heat resistant. It ranks as the second-most-used plastic worldwide. Although the density of polypropylene increases when fillers are added, pure PP has the lowest density of any commercial plastic.Due to high strength PP also suitable for variety of purpose in machining industry.

Polypropylene's benefits

Plastics made of polypropylene maintain their shape after torsion or bending and have strong chemical resistance. Additionally, PP has a high melting point and won't break down when in contact with moisture or water. The name for this plastic, injected molded PP, can be recycled up to four times. Additionally, recycled PP can be blended with other types of plastic.

Application in Automotive

One of the most often utilized materials in the production of automotive components is polypropylene, a polymer of propylene. It is frequently utilized in the production of exterior automotive parts like bumpers due to its resistance to chemicals, UV light, and water. It is also employed for cable insulation.

Photo by Mastars on Unsplash

Injection Molding Techniques

Three primary types of injection molding techniques—thermoplastic injection molding, elastomeric injection molding, and thermosetting injection molding—are typically used in the automotive machining sector.

Injection molding for elastomers

Rubber and silicone-based elastomeric materials are used in elastomeric injection molding to create parts. Many of its benefits, such as its affordability, rapid manufacturing, and adaptability, are shared with thermoplastic injection molding. Additionally, it offers greater vibration and shock dampening.

Thermosetting Injection Molding

Thermosetting injection molding is employed to create parts from thermosetting materials like epoxy and polyester. The exact dimensional tolerances and reproducibility of this kind of vehicle molding are among the many benefits that are shared with thermoplastic molding. In comparison to thermoplastic molding, it also has a few benefits.

The main reason car manufacturers favor thermosetting injection molding is that it is not prone to melting or deforming at high temperatures. Due to its unique properties it also favorable for milling shop.

Thermoplastic Injection Molding

In the automotive sector, thermoplastic injection molding is the most typical kind of injection molding. Parts manufactured of thermoplastic polymers including polypropylene, nylon, and ABS are produced using it.

The low cost, quick output, and versatility of this auto molding method make it superior to other methods of injection molding.

Injection Molding Application in the Automotive Industry

One of the most often utilized production methods for plastics is injection molding. This is understandable given that it presents a workable method for mass-producing high-quality injection-molded vehicle parts using a variety of polymers and unique milling shop. Automobile plastic injection molding is a crucial production technique in the automotive sector, where reliability, safety, and quality are of the highest importance.

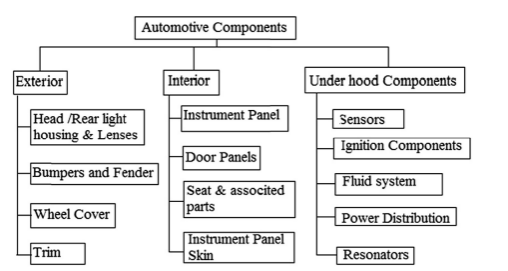

We are unable to name every component because the list of injection molded goods used in the auto industry is so extensive. As a result, we have separated the auto parts into three categories: exterior, interior, and under-the-hood components.

Which of these components was produced using plastic injection molding? Let's find out.

Categories of automobile parts

Exterior Parts

Injection molding is a well-recognized process for producing a variety of exterior car elements, including fenders, grilles, bumpers, door panels, floor rails, lamp housings, and others. Splash guards are a fantastic example of how durable injection molded components can be. Rubber and other resilient materials are widely used in the parts that protect the car from road debris and minimize splashing.

Exterior parts of a car

Interior Parts

The whole inside of the car, including the dashboard, door handles, center consoles, and compartments on the dashboard, is made entirely of injection-molded components. Furthermore, the same manufacturing process is used to create all beautiful automotive moldings found in luxury vehicles.

Interior parts of a car

Parts under the Hood

All of the engine accessories previously found under the hood were constructed of metal. The automotive machining industry have switched to plastic, however, as a result of the extensive usage of injection molding. Plastics can be used to produce sensors, cylinder head coverings, oil pans, and electrical kits.

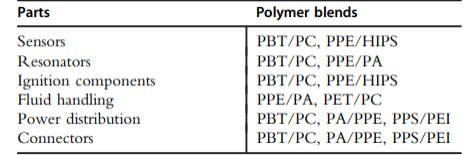

Underhood application of polymers

When choosing materials for under-hood applications, some crucial considerations are chemical resistance, high modulus at increased temperatures, severe UV and dimensional stability considerations, low specific gravity, good heat ageing, and good processability. temperature is taken into account.

Several of the polymer mixtures that are Relevant underhood components are displayed in the following image

Photo by C Joyful on Unsplash

Advantages of the Injection Molding

The use of injection molding is becoming more and more widespread, especially as new technologies are developed. With its expansion come new possibilities for utilizing various components created using this approach in the production of automobiles. Currently, a greater proportion of plastic injection molded components is being used in modern car designs across the globe. The advantage of injection molding is that it can meet the demand that is only growing.

Enables the Manufacturing of Numerous Vehicle Parts

Integral automobile parts can be produced more naturally due to plastic injection molding. It assists with budget management and project scheduling. Regardless of the vehicle design, injection molding can quickly produce a large number of components.

The automotive sector gains a great deal from injection molding, particularly when producing engine hoses and tubes, knobs, door handles, clips, and engine housing covers, among other things.

Produces lighter materials

Amazing productivity benefits are provided by plastic injection molding. Automotive parts can incorporate cutting-edge safety measures as well as other sustainable functions due to the use of lightweight materials in manufacturing.

Additionally, employing injection-molded components can reduce carbon emissions providing production sustainably.

Photo by Mastars on Unsplash

High Tolerance and Surface Finishes

The fact that plastic injection molding aids the automotive sector in producing parts with high tolerance and little fault chances is one of the most important benefits. Injection molding enables milling shop to achieve the finest features in various automobile components. Errors are reduced while producing different pieces using this method.

It's important to bear in mind that even a minor production error might have serious implications, such as fuel or oil loss that can harm the engine. With injection molding, you can rest easy knowing that you're getting the greatest possible product.

Reduce Cost and Size Effective

Due to the price of the mold, producing an injection mold can be an expensive process. The technique is still quite scalable, though, and as the machining company produces more pieces, the overall cost goes down. Thus, injection molding is advantageous to the company when used in mass manufacturing. However, injection molding tooling expenses may limit the process's ability to be cost-effective for anything other than mass production.

Complex Shape Design

The capability of injection molding to create parts with intricate shapes is another benefit. Screw precession is a technique used by injection molding machines to inject molten plastic into a mold chamber. This method enables the production of complicated and extremely detailed pieces. Additionally, objects with internal cavities, such as engine intake manifolds, can be produced using injection molding.

Conclusion

In this article, we highlight all the injection molding details related to the automotive machining industry. Injection molding demand is increasing day by day. Thus, In the industrial world, injection molding has a wide range of applications for mass production. The overall cost of production is relatively low once you have recovered your initial investment in molds and tools.

Injection molding appears to be a wonderful option for auto manufacturers to address the growing demand for autos and to create complex automobile parts. Do You have any other query about this blog? Let us know by commenting below.