Discover unparalleled CNC machining services for tailor-made prototypes and high-

volume production components in a diverse range of metals and plastics.

Experience seamless quoting and secure the manufacturing of your custom

parts with competitive pricing.

Secure, confidential uploads. Your designs are safe with us.

Seeking a trusted, swift CNC machining provider? BaiChuan Precision stands out for bespoke metal and plastic components. Our facility, equipped with over 30 advanced CNC machines, is designed for both rapid prototyping and large-scale production machining. Supported by an 18-year legacy and a strategic network of partner shops across the United States, Canada, Europe, Japan, and New Zealand, we guarantee unlimited manufacturing capacity for top-quality parts delivered promptly for each project. Experience our specialized online CNC machining services now!

Discover precision with BaiChuan Precision: your solution for tight tolerances and complex CNC parts. Join our circle of satisfied clients with our bespoke CNC services.

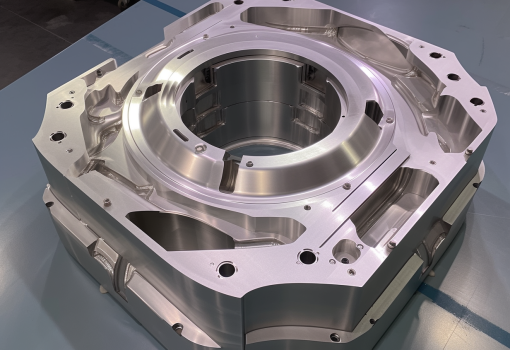

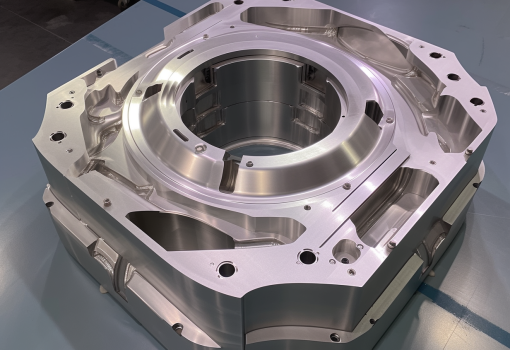

3&5 axis CNC milling service

Precision Unleashed: With over 30 sets of CNC milling machines, we effortlessly mill tight-tolerance, complex geometries in plastic and metal parts, all under the ISO 9001:2015 certified quality management system. Our 3-, 4- and 5-axis milling machines stand ready for cost-efficient solutions. Dive into precision with BaiChuan.

CNC turning service

Efficient CNC Turning: BaiChuan Precision specializes in swiftly creating round components from plastic and metal bars or tubes, perfect for items like worm shafts. With the addition of live tooling, we seamlessly integrate milled geometries in one process. Experience efficiency and precision with BaiChuan.

Explore the pinnacle of precision with BaiChuan Precision, where we transform ideas into reality through our CNC machining expertise. Our gallery is a testament to our dedication to top-quality, customized CNC machined parts, crafted by our skilled team. When it comes to CNC machining solutions, your search ends here with us!

Discover unmatched precision, top-tier quality, and unmatched affordability, no matter the volume. BaiChuan Precision stands ready to meet your needs with speed and expertise.

1 pcs

Get Factory Price Directly

Prototyping 3 Day

7/24 Personalized Collaboration & Strategic DFM Guidance

ISO 9001:2015, provides a QC report for each part

3-, 4-, & 5-axis CNC machines for manufacturing. CMM & XRF analyzer for QC

Dive into the testimonials of our valued partners to discover how we’ve met their unique needs with precision and excellence.

As the owner of a small business that develops new products for our own market and also for other companies, BC has always been very helpful as our main supplier of prototype parts from metals and plastics. For 5-6 years we have relied on BC for various prototypes for a multitude of products made from steel, aluminium, and several plastics. BC are receptive to our needs and are able to source the correct material for customised applications, such as specific grades of non-magnetic stainless steel. BC have also been our partner for manufacturing of stainless steel components for our electric bike business and polycarbonate parts for our drilling alignment monitor, as well as many other productions from a wide variety of products across multiple industries.

Sam Sewell

Bonjour je m'appelle Mickaël, je voulais faire une petite vidéo pour parler de mes retours avec la société Kunshan Baichuan Precision. Si je dois décrire en quelques mots, je dirais: attentif,très impliqué, travail de précision, réactivité et communication aisée. J'ajouterai un grand merci à mon interlocutrice Linda qui a été un soutien et une patience sans faille. Merci.

Mickaël Lauriola

Unlock rapid turnaround times for your CNC prototypes and parts. Enjoy our standard 7-day lead times. Simply upload your design to verify eligibility.

Every part is manufactured with rigorous attention to detail. For those with specific needs, we welcome 2D drawings to guide our production. In the absence of these, indicating tolerances with ISO 2768 standards ensures that we still meet your precise requirements. See the standard we follow and how we make sure the parts meet the requirements.

Aluminum, stainless steel, brass, titanium, copper, ABS, POM, PEEK, and wood material, we pride ourselves on offering an extensive array of industrial-grade CNC machining materials with certification. This diversity ensures that you can select the perfect material to meet the specific requirements of your custom parts, whether for prototyping phases or full-scale production runs.

BaiChuan Precision elevates the standard for CNC machined parts with a comprehensive suite of high-quality surface finishes such as polish, bead blasted, anodized(Type II & Type III), brush, galvanization, powder coat, passivation, electroless nickel plating, and PVD. Our offerings are designed to enhance the aesthetic appeal, durability, and performance of your components, ensuring they meet both functional requirements and visual expectations.

We offer comprehensive custom CNC services tailored to meet the needs of any production volume – from prototyping to high-volume manufacturing of 10,000+ units. Our expertise ensures your transition from initial idea to end-use production parts is seamless and efficient.

Prototyping allows detailed evaluation of appearance, function, and material properties. This crucial step ensures your design is not just viable but optimized for production. We’re committed to quality, precision, and rapid turnaround, streamlining your journey from concept to final product.

We excels in low-volume production, offering custom CNC machining that combines precision, flexibility, and a broad selection of materials. Ideal for runs of custom parts, our approach accelerates market entry while maintaining high standards of quality and consistency.

Whether you require 50 or 20,000 units, our expertise and state-of-the-art CNC technology ensure we can deliver tailored solutions efficiently and cost-effectively. Embrace the BaiChuan advantage to reduce production times and elevate your project with our integrated custom machining services.

We’re not just a provider; we’re your partner in delivering precise CNC machining solutions that meet the rigorous demands of your projects. We specialize in custom CNC machined parts for industries including, but not limited to, the following:

Baichuan is equipped with large CNC machining centers and welders with extensive experience in welding negative pressure equipment. We have also built a dust-free workshop equipped with a leak detector and a 4-meter-long CMM inspection machine to ensure that the vacuum chambers and accessories we produce can meet the requirements of customers in the semiconductor and photovoltaic industries from processing, welding, and testing.

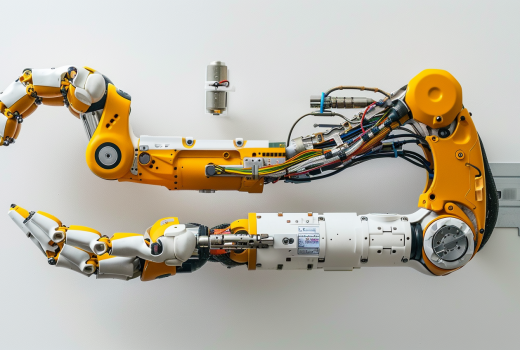

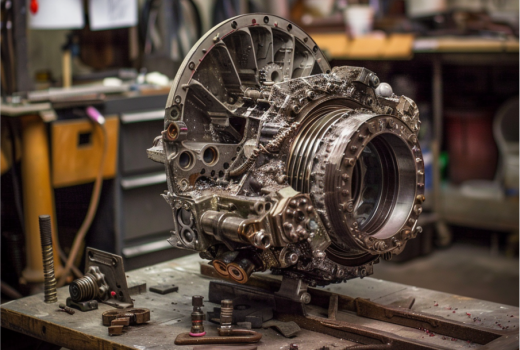

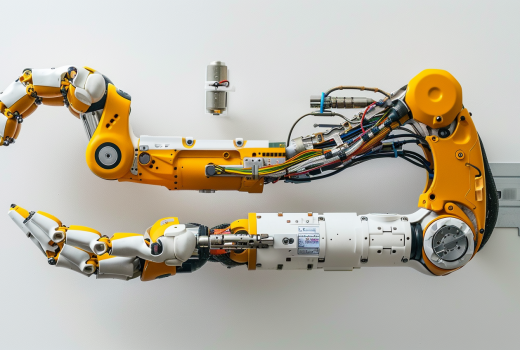

We specialize in creating custom, high-precision components for a broad range of industrial machinery, from automated assembly lines , electronic devices enclosures, and robotics to heavy-duty manufacturing equipment and engine parts.

Our expertise spans the crafting of durable and corrosion-resistant parts for sailboats such as rudder stocks, and mast fittings, alongside precision-engineered deck hardware and custom cockpit components.

Stainless steel or titanium bone plates, prosthetic limbs, components for respiratory devices, handheld medical instruments, diagnostic equipment, anatomical models, and precision surgical tools.

Including fuselage structural parts, seat armrest, landing gear assemblies, and aerospace-grade fasteners. Utilizing advanced materials that meet the stringent requirements for strength, durability, and lightweight performance

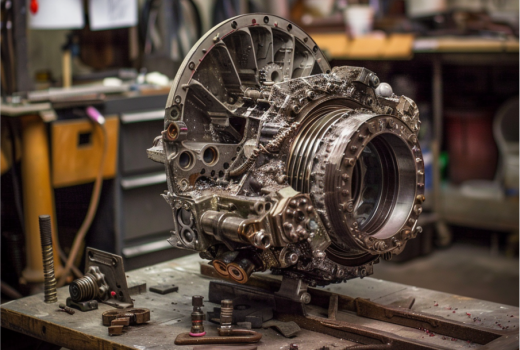

From engine parts, gearbox components, and suspension systems, to bespoke fittings for electric drivetrains and battery enclosures, we utilize advanced materials that meet the rigorous standards for durability, performance, and lightweight design.

Normally, we will provide a quote within 12 hours. If the information you provide is comprehensive, it will allow us to quote you faster.

CAD Files in Any Format: Whether it’s 2D or 3D, we accept STP, IGES, X_T, DWG, PDF, STL, ensuring no design is too complex for us to handle.

Project Specifics: Share your expected quantities, desired machining processes, and material requirements to help us tailor our services perfectly to your needs.

Finishing Touches: Specify any secondary operations such as finishing details, heat treatments, anodizing, or plating to ensure your parts meet the highest standards.

Compliance and Certifications: Let us know about any critical industry standards or customer specifications you adhere to, including First Article Inspection, PPAP requirements, and necessary certifications.

Additional Insights: Any target pricing, desired lead times, or other pertinent information will help us align our services with your expectations.

That’s not a problem. Just send us the photos of each angle, tell us the overall dimesions, material, surface treatment and QTY of the sample, and we will quote an approximate price. If you think the price is right, we then make samples based on the drawings we get and adjust them to perfection.

As an ISO-9001 certified factory, we will strictly follow the tolerance requirements on your drawings. If you don’t know the specific tolerances, you can provide matching products or tools for us to test. Our QC department is equipped with 2 CMMs and dozens of different types of testing instruments, and will provide testing reports for each part.

With a sprawling 5000-square-meter machining shop. Our setup is not just vast; it’s meticulously organized and equipped with 30+ high-performance CNC machines and our team of 50+ skilled professionals which operates 24/7. This relentless work ethic ensures we can deliver over 500 machining projects and more than 30,000 machined parts per month, keeping your projects on schedule every time.

Milling: 6500*4200*1800mm

Lathe: 1600*1400mm

Checking: CMM 4000*2000*1500mm

You can download our equipment list here to know the details.

We are a manufacture, so you can get the most real price without talk to a middle man and also save time!

Lead times are based on quantity and product complexity. For normal products, 3-7 days to get 1 pcs, and 20 – 25 days to get 300 – 500 pcs. We will send videos or photos every two days or when the product enters every stage, such as drawing confirmation, material purchase, rough machining, precision work, surface treatment, and the final finished product, so that you can know the situation at the first time.

Embark on a seamless CNC machining experience with BaiChuan Precision, where your prototypes evolve into production with unmatched quality, speed, and cost-efficiency.

CNC machining is a manufacturing process known for its precision and versatility in creating parts with complex shapes and high levels of detail. CNC stands for Computer Numerical Control, which means that the machines involved in this process are controlled by computers.

CNC Mills: These machines perform cutting and drilling operations to create parts of various shapes and sizes. CNC mills can move along multiple axes (at least 3 but often 5 or more) to create complex geometries with high precision.

CNC Lathes: Used for turning operations, CNC lathes spin the workpiece against a cutting tool to shape it. They are typically used to create cylindrical parts with precise dimensions.

CNC Routers: Similar to mills but generally used for softer materials like wood, plastics, and foams. CNC routers are widely used in carpentry and sign making for cutting, engraving, and shaping.

CNC Grinders: These machines use a rotating grinding wheel to remove material and achieve a fine finish or tight tolerance on a workpiece. CNC grinders are used for metalworking and creating parts that require a high surface quality.

CNC Plasma Cutters: Plasma cutters use a plasma torch to cut through metal materials, such as steel, stainless steel, and aluminum, quickly and accurately. They are often used in fabrication and construction.

CNC Electric Discharge Machines (EDM): Also known as spark machining or die sinking, EDM uses electrical discharges to shape a workpiece by removing material. It’s used for hard metals and creating intricate shapes that are difficult to achieve with other machining processes.

CNC Laser Cutters: These machines use a high-powered laser to cut or engrave materials like metal, plastic, or wood. Laser cutters are known for their precision and ability to create complex contours.

CNC Waterjet Cutters: Waterjet cutting uses a high-pressure stream of water, sometimes mixed with an abrasive substance, to cut through materials. It’s notable for its ability to cut without introducing heat or stresses into the material.

In CNC machining, a piece of raw material (metal, plastic, wood, etc.) is cut and shaped into a final product through a controlled material-removal process. This is achieved by a computer program that precisely controls the movement of the machinery and tools based on pre-programmed software and codes.

CNC machining offers several benefits, including high precision, repeatability, and efficiency. It can produce parts with complex geometries that might be difficult or impossible to achieve with manual machining. Additionally, once the setup is completed and the program is verified, the CNC machine can run virtually unattended and produce parts with consistent quality.

Secure, confidential uploads. Your designs are safe with us.

3&5 axis CNC milling service

Precision Unleashed: With over 30 sets of CNC milling machines, we effortlessly mill tight-tolerance, complex geometries in plastic and metal parts, all under the ISO 9001:2015 certified quality management system. Our 3-, 4- and 5-axis milling machines stand ready for cost-efficient solutions. Dive into precision with BaiChuan.

CNC turning service

Efficient CNC Turning: BaiChuan Precision specializes in swiftly creating round components from plastic and metal bars or tubes, perfect for items like worm shafts. With the addition of live tooling, we seamlessly integrate milled geometries in one process. Experience efficiency and precision with BaiChuan.

Baichuan is equipped with large CNC machining centers and welders with extensive experience in welding negative pressure equipment. We have also built a dust-free workshop equipped with a leak detector and a 4-meter-long CMM inspection machine to ensure that the vacuum chambers and accessories we produce can meet the requirements of customers in the semiconductor and photovoltaic industries from processing, welding, and testing.

We specialize in creating custom, high-precision components for a broad range of industrial machinery, from automated assembly lines , electronic devices enclosures, and robotics to heavy-duty manufacturing equipment and engine parts.

Our expertise spans the crafting of durable and corrosion-resistant parts for sailboats such as rudder stocks, and mast fittings, alongside precision-engineered deck hardware and custom cockpit components.

Stainless steel or titanium bone plates, prosthetic limbs, components for respiratory devices, handheld medical instruments, diagnostic equipment, anatomical models, and precision surgical tools.

Including fuselage structural parts, seat armrest, landing gear assemblies, and aerospace-grade fasteners. Utilizing advanced materials that meet the stringent requirements for strength, durability, and lightweight performance

From engine parts, gearbox components, and suspension systems, to bespoke fittings for electric drivetrains and battery enclosures, we utilize advanced materials that meet the rigorous standards for durability, performance, and lightweight design.

Embark on a seamless CNC machining experience with BaiChuan Precision, where your prototypes evolve into production with unmatched quality, speed, and cost-efficiency.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.