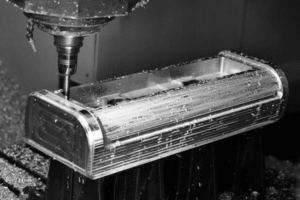

Custom CNC-Machined Spreaders: Balancing Strength and Weight

In this blog, we will explore what CNC-machined spreaders are, why the strength-to-weight ratio matters, their key design factors, manufacturing challenges, and more. So, keep reading!

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

In this blog, we will explore what CNC-machined spreaders are, why the strength-to-weight ratio matters, their key design factors, manufacturing challenges, and more. So, keep reading!

Effective welding defect repair requires systematic assessment, appropriate method selection, and rigorous quality verification. By understanding defect characteristics and repair impacts, manufacturing engineers can restore component integrity while minimizing costs and production delays.

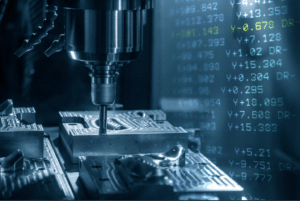

Recognizing G-Code basics is essential for fast and safe CNC machining. All feed commands (F, G94, G95), spindle command (S, M3, M4, M5), and tool change commands (T, M6, G43) application is directly related to surface finish, tool-life, and safety in machining.

Ultrasonic flaw detection has transformed our approach to quality control, helping us deliver defect-free precision components. By revealing hidden flaws that other methods miss, this technology ensures safety, reliability, and customer confidence in every part we manufacture.

Whether used on a racing yacht, an offshore crane, or a high-rise lift system, precision-machined fairleads and sheaves help ensure that the system runs cleaner, longer, and more reliably.

Optimizing lightweight marine hardware production requires specialized materials, advanced multi-axis machining techniques, and rigorous quality control.

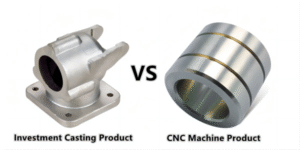

In a nutshell, components created by CNC machining provide the exacting strength and peace of mind that are critical in marine applications. They are far more enduring and precise than any cast or welded parts.

The precision, dimensional accuracy, and material integrity provided by CNC machining ensure that rudder stocks can withstand the intense stress loads and harsh conditions of competitive sailing.

The introduction of CNC machining has transformed the marine sector by offering micron-level precision, repeatable tolerances, and durable edge finishes able to withstand saltwater corrosion, biofouling, and extreme pressure.

Achieving precision tolerances in sailboat winch manufacturing demands specialized knowledge in material selection, vibration control, quality verification, marine-specific adaptations, and advanced finishing techniques.

Compared to stainless steel, titanium, or composite alternatives, anodized aluminum consistently delivers the best performance-to-cost ratio, especially when weight, customization, and visual appeal matter.

While 316L stainless steel remains a cost-effective option for many applications, titanium’s exceptional longevity, minimal maintenance, and superior safety margin make it the clear choice for critical sailing hardware despite higher initial costs. Your specific sailing needs should guide this important material decision.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.