What is Oxyfuel gas welding (OFW)?

Oxyfuel Gas Welding (OFW) is a welding method that uses oxygen and a mixture of different fuels to produce a flame. The main distinction between

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

Oxyfuel Gas Welding (OFW) is a welding method that uses oxygen and a mixture of different fuels to produce a flame. The main distinction between

We will uncover a detail on what is CNC machining, how CNC Machining is different from other machining techniques, and how it works. Do you think it going to be boring? Exactly No! Don’t worry! It will not be a historical lecture instead you will learn interesting information on how CNC Machining is ruling in every product manufacturing industry.

Arc welding is the name given to a class of welding processes that melt and fuse metal together using an electric arc as the heat source. To create a joint between the metals, this method may or may not need pressure or filler metal.

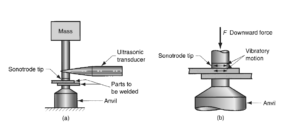

Ultrasonic welding (USW) is a solid-state welding process where two components are joined by applying high-frequency oscillatory shear stresses while under modest clamping force. This procedure, which is frequently employed in lap welding (as shown in Fig. below), breaks off surface coatings and permits close contact between the components, forming a strong metallurgical bond.

Diffusion welding (DFW) is a solid-state welding technique that produces a strong bond by facilitating diffusion and coalescence under controlled conditions using heat and pressure. Because it may prevent common metallurgical difficulties observed in conventional welding procedures, this specialized technology is vital in the field of metallurgy.

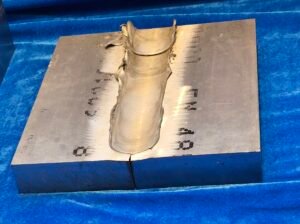

Friction stir welding (FSW) is a solid-state welding technique that forms the weld seam by manually stirring the metal to create friction heat and feeding a spinning tool along the joint line between two workpieces.

Welding is a material joining process where two or more parts are coalesced at their contacting surfaces through the application of heat and/or pressure.

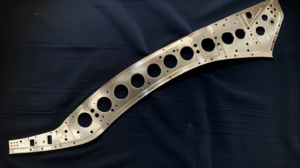

Thin wall machining is a CNC machining process focused on creating precise cuts and shapes in materials with thicknesses typically less than 2mm. Its main objective is to manufacture intricate components with delicate, thin features that demand the utmost accuracy.

Vacuum chambers are integral to numerous scientific, medical, and industrial applications, necessitating extremely high standards of accuracy and reliability. Proper post-processing is crucial in ensuring these standards are met by enhancing the physical and chemical properties of the chambers. This comprehensive guide explores the sophisticated post-processing steps such as cleaning, heat treatments, and surface treatments that are essential for crafting top-quality vacuum chambers.

Welding is an indispensable technique across various industries, pivotal for constructing everything from small tools to large infrastructures. Its applications in precision manufacturing, especially in making vacuum chambers, underscore the critical role of choosing the right welding process for specific materials.

Friction Stir Welding (FSW) is a solid-state joining technique that uses a non-consumable tool to create high-strength joints without melting the base materials. Ideal for sensitive manufacturing environments like vacuum chambers, FSW offers enhanced joint integrity, reduced distortion, and high durability, making it indispensable in industries requiring impeccable vacuum seals and structural strength.

When selecting a material for vacuum chambers, aluminum offers lightweight properties and cost-effectiveness, stainless steel provides durability and corrosion resistance, and titanium stands out for its superior strength-to-weight ratio and exceptional corrosion resistance.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.