How do engineers make sure vacuum chambers—which are necessary for many high-tech applications—continue to operate flawlessly over time? What role do plating and surface coatings play in highlighting these important elements? Understanding the effects of various post-processing of vacuum chamber approaches becomes more crucial as the need for reliability and precision in industrial systems increases. Vacuum chamber protection and improved functionality depend on surface coating and plating, which is more than aesthetics.

However, what precisely are the components of these processes? What technologies are advancing these techniques and how do they impact the chamber's performance? We'll look at these and other issues in this post, revealing the critical part surface coating and plating play in the durability and efficiency of vacuum chambers.

I. Types of Surface Coatings in Vacuum Chambers

Surface coatings in the post-processing of vacuum chambers offer resistance to wear, corrosion, and high temperatures, are essential for improving the functionality and longevity of vacuum chambers. The following are among the most typical forms.

PVD (Physical Vapour Deposition) Coatings

PVD operates by vaporizing material and depositing it onto a surface in a vacuum. It produces strong, thin coatings that are exceptionally robust and resistant to wear.

Common varieties include Aluminium Titanium Nitride (AlTiN) for high-temperature applications, Chromium Nitride (CrN) for corrosion resistance, and Titanium Nitride (TiN) for hardness.

Chemical Vapour Deposition (CVD) Coatings

CVD deposits a coating from gaseous precursors by chemical reactions. CVD is more suitable for high-temperature and chemically hostile settings than PVD and yields thicker, more consistent coatings.

Sputter Coating:

The process of sputter coating is ion-bombarding a target substance to release atoms that settle on a substrate. For intricate shapes and high-wear components, it offers consistent, robust adhesion coatings. They do wonders to improve wear resistance and electrical conductivity.

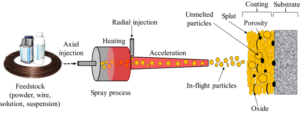

Thermal Spray Coating:

Thermal spray techniques include melting a material and spraying it onto a surface. Examples of these processes are plasma spray and high-velocity oxygen fuel (HVOF). HVOF uses supersonic particle spraying to produce coatings that are dense and highly adhesive. In hostile situations, it is perfect for resistance to erosion and corrosion. HVOF uses high-speed oxygen fuel combustion to create dense, wear-resistant coatings, whereas plasma spray uses ionized gas to achieve high temperatures.

II. Plating Processes for Vacuum Chambers

The application of coatings and platings in the post-processing of a vacuum chamber provides protective layers that fend against oxidation, corrosion, and wear, is essential to extending the life and functionality of vacuum chamber parts. The following are typical plating methods:

Electroplating

Electroplating is a technique that deposits a metal layer from a solution onto a substrate using an electric current. It improves the appearance and resistance to corrosion surfaces.

Electroless Plating

Electroless plating is a chemical technique that deposits metal on a substrate without the need for electricity. This procedure is autocatalytic, it will go on as long as the chemical reactions are maintained. Common Materials: Copper for electrical conductivity and nickel for corrosion resistance are two materials that are frequently utilized.

Hard Chrome Coating

The hardness and durability of a surface are highly significant factors. Hard chrome plating offers a robust and resistant surface that prolongs the life of vacuum chamber components. In addition to preventing corrosion and abrasion, it lowers friction.

Applications: Perfect for components like seals and bearings that are subjected to a lot of wear and friction.

Gold Plated

The process of gold plating involves coating a substrate with a thin layer of gold. It is employed to enhance aesthetic attributes, corrosion resistance, and electrical conductivity.

Applications: These are frequently found in vacuum chamber connectors and electronic components where high dependability is crucial.

III. Surface Preparation Before Coating/Plating

For coatings or plating to adhere strongly and perform at their best on vacuum chamber components, proper surface preparation is necessary. The principal actions consist of:

1. Scrubbing and Grease Removal

The first stage of coating/plating in post processing of vacuum chamber is cleaning the surface of impurities such as dust, oils, and residues. Efficient cleaning guarantees correct adhesion and expected performance of the coating or plating.

2. Mechanical Surface Treatment

A roughened surface is produced by mechanical treatments like sanding, grinding, or shot blasting. Through surface area expansion and defect removal, this enhances coating or plating adhesion.

3. Chemical Etching:

The process of chemical etching involves roughening and activating the surface with acids or other chemicals. Through the creation of a reactive surface layer that clings more readily to the coating material, this technique strengthens the bonding strength of coatings.

Coating and Plating Considerations for Vacuum Chambers

A number of important criteria need to be taken into account when choosing coatings or plating for post-processing of vacuum chambers in order to ensure performance, durability, and compatibility with the chamber's operating environment: There are following factors to be considered carefully.

1. Material Compatibility

Selecting the appropriate plating or coating material is essential for vacuum chambers to guarantee optimal performance and prevent contamination. The coating materials have to be compatible with both the base material of the vacuum chamber and the gases and chemicals that will be involved during operation. Depending on the particular use case, common options include copper, gold, or nickel. Maintaining vacuum integrity requires ensuring that there is little reactivity between the coating and the chamber environment.

2. Thermal and Electrical Properties

To fulfill the vacuum chamber's functional requirements, coatings must be chosen according to their electrical resistivity and thermal conductivity. For instance, coatings with strong thermal resilience, such as titanium nitride, are frequently chosen in high-temperature settings. Materials like copper or gold are used in applications where electrical conductivity is required. Under variable electrical or thermal circumstances, coatings shouldn't significantly impact the chamber's functionality.

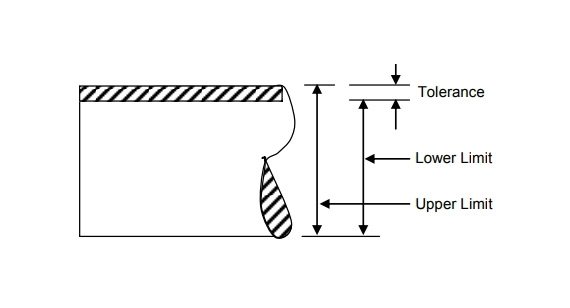

3. Thickness Control

To prevent problems like peeling, flaking, or variations in chamber dimensions, it is essential to regulate the coating's thickness. In vacuum applications, accurate thickness management guarantees that the coating offers sufficient protection without compromising the structural integrity or operational efficiency of the chamber. To attain consistent and regulated coating thicknesses, particularly in crucial regions like joints and seals, processes like sputtering and electroplating are frequently employed.

4. Durability and Longevity

To survive the severe circumstances of vacuum environments, such as exposure to high temperatures, corrosive gases, or mechanical strains, the coating or plating needs to be extremely robust. Longer service life and less frequent maintenance or reapplication are ensured by a durable coating. The hardness and wear resistance of materials like chromium or ceramic-based coatings are typically used to increase the vacuum chamber's operational lifespan.

V. Testing and Quality Control of Coatings/Platings

Determining the dependability and effectiveness of coatings and platings in vacuum chambers requires extensive testing and quality control procedures. Important techniques consist of:

Testing for Adhesion

Adhesion tests verify that there is a strong bond between the coating or plating and the vacuum chamber's surface. Poor adhesion can cause flaking or peeling, which may pollute the area or cause failure when the device is operating. Adhesion strength is assessed using standard techniques such as the pull-off test and tape test. These tests gauge the amount of force needed to separate the coating, confirming that the bond is robust enough to endure the vacuum chamber's operating conditions.

Tests for Corrosion Resistance

In particular, corrosion resistance is essential when vacuum chambers are subjected to corrosive conditions or reactive gases. To evaluate how well the coating or plating prevents corrosion in the chamber, experiments such as immersion and salt spray tests replicate challenging environments.

Tests for Thermal Cycling

Vacuum chamber coatings have to withstand large temperature changes without chipping or deteriorating. Thermal cycling tests simulate the operating conditions of the chamber by repeatedly heating and cooling the coated surface. The experiments show whether the coating, which is essential to preserving the operational stability of the chamber, can withstand abrupt and severe temperature changes while still remaining functional.

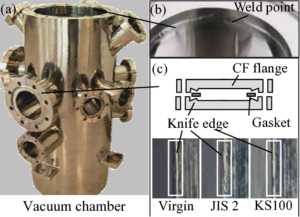

Testing for Vacuum Integrity

Leak Detection:

Leak detection techniques, such as helium leak testing, are required to confirm vacuum integrity following coating or plating. This test verifies that the chamber's ability to maintain a vacuum has not been hampered by coating flaws. Leaks of any size can affect performance, so finding and plugging them is crucial.

Tests for Outgassing:

Outgassing is the term used to describe the gaseous discharge from a covered surface in a vacuum. These gases have the potential to contaminate a vacuum. In order to ensure that the coating has been placed and dried correctly and to reduce the danger of contamination, outgassing tests are carried out to assess the amount of gas released.

VI. Applications of Coated and Plated Vacuum Chambers

The superior durability and performance in harsh conditions of coated and plated vacuum chambers make them indispensable in a variety of industries. Typical uses include:

1. Semiconductors Manufacturing

Vacuum chambers that are coated or plated are necessary to create the exact and regulated conditions needed for the manufacturing of semiconductors. Surface treatments increase process efficiency and guard against contamination.

![]()

1. Defence and Aerospace

The aerospace and defense sectors employ vacuum chambers with specialized coatings to test components in high-vacuum settings. Coatings increase a component's resilience and shield it from adverse environments.

2. Medical Products

When making medical devices, where sterile, contamination-free conditions are essential, coated vacuum chambers are used. Electrical conductivity in sensitive devices is improved by platings such as gold.

3. Optics and Photonics

Mirrors, lenses, and other optical components will perform more effectively due to surface coatings, which increase the reflectivity and longevity of vacuum chambers used in optical coating systems.

4. Research and Development

Scientific research frequently uses vacuum chambers with long-lasting, corrosion-resistant coatings for high- or ultra-high-vacuum tests.

VII. Challenges for Coating /Plating

To guarantee optimal performance, a number of complications with coating and plating vacuum chambers must be resolved.

Adhesion Problems

Strong adhesion between the coating or plating and the vacuum chamber surface can be challenging to achieve, particularly in cases where the materials are incompatible or the surface preparation is insufficient.

Uniform Coating

Comprehending intricate geometries and keeping the thickness constant can be difficult, resulting in uneven performance and possible weak points where the coating might be excessively thick or thin.

Mechanical and Thermal Stresses

In vacuum conditions, coatings and platings have to endure high temperatures and mechanical strains. The materials might peel, crack, or distort if they are not chosen correctly for these circumstances.

Control of Contamination

Maintaining a clean atmosphere constantly is crucial because contaminants introduced during the coating or plating process can damage the vacuum chamber's functionality.

Expense and Time

Certain chambers with complex designs or high-performance standards might require the use of numerous layers or precise techniques, making coating and plating procedures costly and time-consuming.

V III. Future Trends in Coating/Plating

New uses and improved performance in vacuum chambers are being made possible by developments in coating and plating technologies. Important motifs consist of:

- Superior Nanocoatings

The development of ultra-thin, high-performance coatings with improved surface qualities at the nanoscale, greater durability, and resistance to corrosion is being propelled by nanotechnology.

- Methods of Sustainable Coating

Reducing hazardous chemicals and using less energy during plating and coating applications are the main goals of eco-friendly and energy-efficient coating technologies, which are gaining popularity.

- Smart Coatings

The effectiveness and endurance of vacuum chamber systems could be increased by including sensors or adaptive qualities into future coatings, which would enable the surfaces to react dynamically to changes in temperature or pressure.

- Enhanced Wear-Resistant Coatings

The development of novel materials and technologies to extend the lifetime of vacuum chamber components in harsh environments is driving continuous research to push the boundaries of wear-resistant coatings.

- 3D Printing of Coated Parts

The manufacturing of vacuum chamber components might be completely transformed by combining 3D printing and innovative surface coatings, which would provide exact control over surface characteristics and speed up production.

Photo by Minku Kang on Unsplash

Photo by Minku Kang on Unsplash

Conclusion

What qualities, under harsh settings, distinguish a genuinely dependable vacuum chamber? In what ways do surface coatings and platings contribute to increased performance and longevity? Post-processing of vacuum chambers can be effectively shielded from wear, corrosion, and severe temperatures by selecting the appropriate coating or plating procedure, as we have shown. However, what awaits ahead?

How will new developments in sustainable manufacturing methods, nanocoatings, and smart materials change the way vacuum chambers are built and maintained? Keeping up with these developments will be essential to achieving new performance and dependability levels as technology continues to grow.

Photo by

Photo by