Does it seem like your metal components are wearing out or failing far too often? In situations where components bear a heavy amount of stress, standard treatments may not be sufficient. Well, nitriding treatment helps in such scenarios.

This advanced heat treatment improves strain resistance, protects against wear and corrosion, and extends the life of components—all without any dimensional change. If constant replacements and expensive halts to productivity are your concern, read on to learn how nitriding can be the best answer!

1) What is Nitriding?

Nitriding is one of the surface heat treatment techniques that enhances the effectiveness and hardening of the surface of metal parts. It improves the fatigue strength and corrosion protection through alterations of just the surface layer. And, such properties are useful in the aerospace, automotive, and tool manufacturing industries.

The process consists of the step of introducing nitrogen to the surface of a certain metal. This nitrogen will bond with some elements of the steel, which serve to deepen its hardness; these elements include chromium, molybdenum, and aluminium. These bonds can reinforce the surface while the core remains tough and flexible.

One of the advantages of nitriding is that it doesn't involve any pumping or heat shock, so it's less traumatic than carburizing or hardening. As a result, the components retain their shape and size, which becomes important when dealing with shrinking and expanding tight-fit machined parts.

Generally speaking, nitriding works best on ferrous alloys and low-alloy steels, which have nitride-forming elements. In addition, certain stainless steels and tool steels also respond favorably to this treatment.

2) How Nitriding Works

Nitriding is a type of surface hardening treatment that increases the amount of nitrogen in a metal's outer layer. It results in the formation of a hard, protective, wear-resistant surface. Here is how it works, step-by-step:

Step 1) Surface Preparation

This process starts with the cleaning of the parts. Grease and oil, as well as rust, dirt, or old paints and coatings, are removed through some form of chemical or mechanical cleaning. The surface must be smooth to enable the nitrogen to diffuse into the metal more uniformly and thoroughly.

Step 2) Heating in Furnace or Chamber

The parts can then be put in a certain atmosphere described below:

- Sealed furnace for gas nitriding,

- Vacuum chambers for plasma (ion) nitriding

- Molten salt baths for salt bath nitriding.

The selection here is based on your specific application, size of the component, its material, and environmental considerations.

Step 3) Heating to the Specified Temperature

The furnace or chamber is then brought to a temperature of 500°C to 550°C, which does not exceed 550°C. This range is mild when compared to other treatments, reducing the likelihood of bowing or warping of the part.

Step 4) Nitrogen Introduction

At this stage, nitrogen is introduced into the environment:

- Gas nitriding uses ammonia (NH₃).

- In plasma nitriding, a mix of nitrogen and hydrogen gases is subjected to an electric current to produce plasma.

- In salt bath nitriding, the source of nitrogen is the molten salt containing cyanate ions.

Step 5) Nitrogen Diffusion and Nitride Formation

Slowly, nitrogen atoms diffuse into the surface of the metal. There, they react with aluminium, chromium, and molybdenum, creating hard nitride compounds. Depending on the process's duration and temperature, this layer can reach thicknesses of 0.1mm to 0.7mm.

Step 6) Cooling

The part is cooled slowly in the chamber after the entire process. This no-quenching method maintains the part's shape and dimensions.

3) Types of Nitriding Processes

Nitriding can be achieved by several processes, each with its own benefits. Methods might vary, but the objective remains the same: to infuse the surface of a metal with nitrogen. The following are the most recognised types:

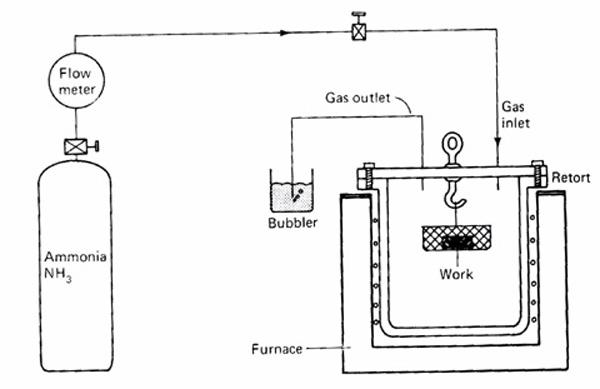

i) Gas Nitriding

It is the most common method of nitriding. It involves the heating of the metal part to be treated within a closed furnace chamber from which ammonia (NH₃) gas is introduced.

Well, as gas decomposes at high temperatures, it releases nitrogen, which permeates into the surface of the metal part. Gas nitriding is reliable, efficient, and economical. Best suited for mass production, it is prevalent in the automotive and tooling industries.

ii) Plasma (Ion) Nitriding

It is a more up-to-date technique. It occurs in a vacuum chamber where a mixture of gases, commonly nitrogen and hydrogen, is converted into plasma with the help of electrical energy. This plasma generates a glowing halo around the part, which aids in the absorption of nitrogen.

Plasma nitriding offers superior control of the depth and hardness of the nitrided layer. Additionally, compared to gas and salt methods, it is greener and less polluting.

iii) Salt Bath Nitriding

In this technique, the component is immersed in a molten bath where salts containing nitrogen compounds, such as cyanate, are found. The heat and nitrogen-rich salt bath penetrate into the metal. Although salt bath nitriding is fast and effective, it is less common now because of the environmentally harmful waste created.

4) Benefits of Nitriding Treatment

If you are looking for the metal parts to be as tough, durable, and reliable as possible, then nitriding treatment offers numerous benefits. Some of them are outlined below:

+ High Surface Hardness: As aforementioned, nitriding treatment creates an outer layer that is very tough, which increases the life of the metal parts. The hardened surface of the part will prevent it from wear and tear. Apart from this, it is also suitable for components that endure consistent fan friction or significant pressure.

+ Improved Fatigue Strength: In addition, it increases fatigue strength, which means parts can sustain repetitive damaging stressed load cycles without the risk of cracking or breaking. These attributes make it ideal for constantly moving gear, crankshafts, and camshafts.

+ Impressive Resistance to Corrosion Damage: The nitrided surface is more resistant to rust and chemical damage, more so when the base materials are stainless or alloy steels. This increases the longevity of the components even when it is used in harsh environments.

+ Quenching Not Needed: Other heat treatments rely on a quench (sudden cooling) to finish the process, but this does not apply to nitriding. This lowers the chances of cracks or distortion occurring, which is very useful when dealing with precision parts.

+ Shape Retention: Lower temperatures alongside no phase changes during the nitriding process mean that the workpiece retains its shape and size. This is beneficial for tools and mechanical parts that require tight accuracy.

+ Extended Operational Life: Because of the component’s hardened surface and resistance to stresses, the nitrided part usually operates for a longer period before repairs or replacement are necessary. Over time, this can be very beneficial in terms of time and cost.

For such reasons, many industries, including automotive, aerospace, tooling, and machining, have trusted and relied on the nitriding process ( We will discuss applications in detail in the coming parts). If you are looking for those parts to perform exceptionally and withstand the test of time, nitriding is a process to consider.

5) Disadvantages of Nitriding

Despite the benefits that come with nitriding, there are limitations that you should consider before using it on your parts. Like all other processes, it has its own set of drawbacks that will not suit every scenario.

- Takes a Long Time to Process: One of the main disadvantages is that nitriding takes a lot of time. Some processes can take anywhere between ten and a hundred hours for you to achieve a desired depth and hardness. If you’re pressed for time, this may not be the most suitable choice.

- Limited to Specific Steels: It does not respond to every single metal, as nitriding is selective. It is primarily effective on steels that have chromium, molybdenum, or aluminium. These assist in forming strong nitrides. In case your material does not contain these elements, you will not benefit maximally from this process.

- Expensive Equipment: Equipment used for nitriding, particularly plasma nitriding, can be costly to purchase as well as maintain. Increased production costs may be an issue, particularly with small batch sizes.

- Difficult to Treat Sharp Edges Even: Treating parts with sharp corners or intricate geometries can be more challenging to achieve a uniform treatment. Uneven exposure to nitrogen in some areas leads to inconsistent surface layers.

- Not Suitable for Soft Metals: Low-carbon soft steels show little change after nitriding. These materials may have a poor bond with nitrogen, meaning surface hardening processes will not be very efficient.

- Environmental Issues (Salt Bath Method): Use of chemicals in salt bath nitriding is costly and poses environmental risks if not done correctly. There are special considerations for waste streams and safety with the personnel.

As with all nitriding processes, these disadvantages should be evaluated about the specific requirements of the project.

6) Applications of Nitriding

Nitriding is a common practice in industries that require components to have high strengths and good durability, and wear resistance. As only the surface is hardened while the core remains tough, the component endures considerable stress or friction. Below are a few applications where the components are routinely used.

- Parts in the Automobiles

The use of nitriding is prominent in an engine and a transmission system. For critical components such as crankshafts, camshafts, gears, and some valve components, improved wear resistance and fatigue strength are vital to extend the engine's life.

- Parts in the airplanes

Each component in an aircraft experiences very high levels of pressure and temperature during operation. Lightweight yet tough and reliable components, such as shafts, landing gear parts, and some engine components, are tough and reliable over time, and they require tough components and so nitride-treated components are used.

- Tooling and Dies

Tools such as injection molds, extrusion dies, and punches are used repeatedly. Nitriding helps maintain their original shape by reducing wear, downtime, and increasing production life.

- Machinery and Mechanical Equipment

Components like bearings, pistons, and hydraulic parts associated with heavy-duty machines are often nitrided. These components function more efficiently and have a longer service life when friction and stress are minimised on their surfaces.

- Medical and Dental Tools

Certain stainless steel surgical and dental instruments are nitrided to enhance hygiene and resistance to corrosion, particularly for use in sterilised environments.

- Firearms and Defence Equipment

Nitriding helps to prevent rust on barrels, slides, and triggers while also improving wear resistance. This is done without extra coatings, which makes it a preferred method.

Nitriding helps components perform optimally and extends their lifespan. It is a reliable method wherever a resilient surface is required without affecting core strength.

7) Nitriding vs. Other Heat Treatments

As with other techniques, nitriding is a form of heat treatment to improve metal parts. In order to explain why one may opt for nitriding, let’s discuss some other common methods like carburizing, induction hardening and case hardening.

Nitriding vs. Carburizing

Both techniques enhance the surface hardness of steel, but carburizing is more carbon-intensive than nitriding, which uses nitrogen. Carburizing is a two-stage process: it needs a high temperature, approximately 900°C, which is later followed by quenching. This can easily lead to parts warping.

Nitriding operates at much lower temperatures, between 500 and 550 °C, and does not require quenching. This results in better stability and reduces cracking risk.

Nitriding vs. Induction Hardening

With induction hardening, only the surface of a part is warmed using electric currents and subsequently cooled down rapidly. While this approach creates a hard layer efficiently, it can be overly aggressive, damaging parts and altering their dimensions.

In contrast, nitriding is slower than induction hardening, giving the process gentler, allowing for better precision components.

Nitriding vs. Case Hardening

Case hardening encompasses various methods such as carburizing and carbonitriding, all of which form a hard exterior layer. Often, these methods require additional corrective work like machining or grinding.

Nitriding does not require any finishing work, which makes it more time and cost-efficient.

For components that require a strong surface that resists wear and with very little distortion, nitriding is usually the safest and most dependable option.

8) Factors Affecting Nitriding Results

Several critical factors influence nitriding success. Following best practices in each factor will improve the results.

! Metal Composition: Not all metals react favorably to nitriding. Steels that contain chromium, molybdenum, aluminium, and vanadium perform best because these metals make strong nitrides. If your material is lacking in these elements, then the surface hardening would be suboptimal.

! Cleanliness of the Surface: Clean and polished surfaces ensure uniform diffusion of nitrogen into the metal. Any form of contamination, be it dirt, oil, rust, rough surfaces, and so on, will lead to non-uniform hardening and weaken structural integrity. This highlights the importance of nitriding surface preparation and cleansing.

! Time and Heating: Treatment of the specimen is done in the furnace at temperatures ranging from 500°C to 550°C for several hours. Deeper penetration of nitrogen requires extending treatment time up to a limit. Extended time, however, leads to brittleness, meaning there must be a balance.

! Source of Nitrogen and Its Flow Rate: The type of nitriding process, whether it is gas, plasma, or salt bath, determines how nitrogen is delivered. Nitrogen and its flow rate must be optimal.

! Control of Production Equipment: Modern furnaces allow for more accurate gas control and precise temperature settings. Poor control of either gas or heat will cause uneven or weak nitriding.

Through close attention to these gas and temperature settings, you can create a high-quality nitrided surface that is strong, smooth, and durable.

9) Conclusion

Nitriding is an effective technique for improving the strength and durability of various metal components. It enhances surface hardness, minimizes wear, and retains the original shape of the component. Nitriding is beneficial to various industries due to its versatility and adaptability with modern technologies and the multiple options provided. For your upcoming projects, nitriding will be the most efficient method if you want powerful results with minimal failures.