Specializing in providing customized processing services for sailboats, J-class yachts, yachts, and ship parts.

Whether it is aluminum alloy, stainless steel, or titanium alloy parts processing, our team can provide you with the best solution.

ISO 9001:2015

Secure, confidential uploads. Your designs are safe with us.

We can meet our customers’ stringent requirements for high precision, high durability, and customized sailboat parts with years of industry experience and leading technology.

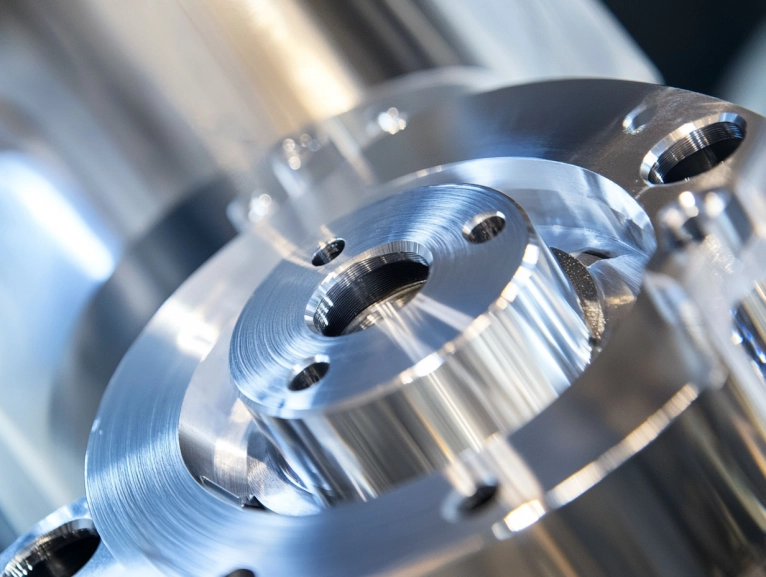

CNC machining, with its precision and versatility, can help manufacture various types of sailboats. Whether it’s racing yachts, recreational sailboats, or custom-designed vessels, CNC machining processes a variety of materials, ensuring precise cutting and perfect fit to meet diverse design and performance requirements.

With advanced equipment and exquisite craftsmanship, we can conduct accurate CNC machining according to customers’ unique needs. Whether it’s complex shapes or high-precision dimensional requirements, they can all be achieved through professional programming and operation, ensuring that each custom part meets the highest standards.

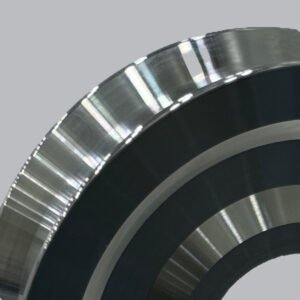

We master a variety of special surface treatment technologies. Grinding can make the part surface smooth without burrs. Sandblasting gives a unique texture and enhances coating adhesion. Anodizing improves corrosion resistance and hardness. Electroplating provides a decorative appearance and protection. Each treatment is carefully regulated to achieve the best results.

We have a complete material supply chain and can provide various special stainless steels meeting military standards, as well as titanium alloys, aluminum alloys and other materials. We can conduct spectrometer detection and provide material reports to understand the specific performance parameters of the material (such as tensile properties and other parameters).

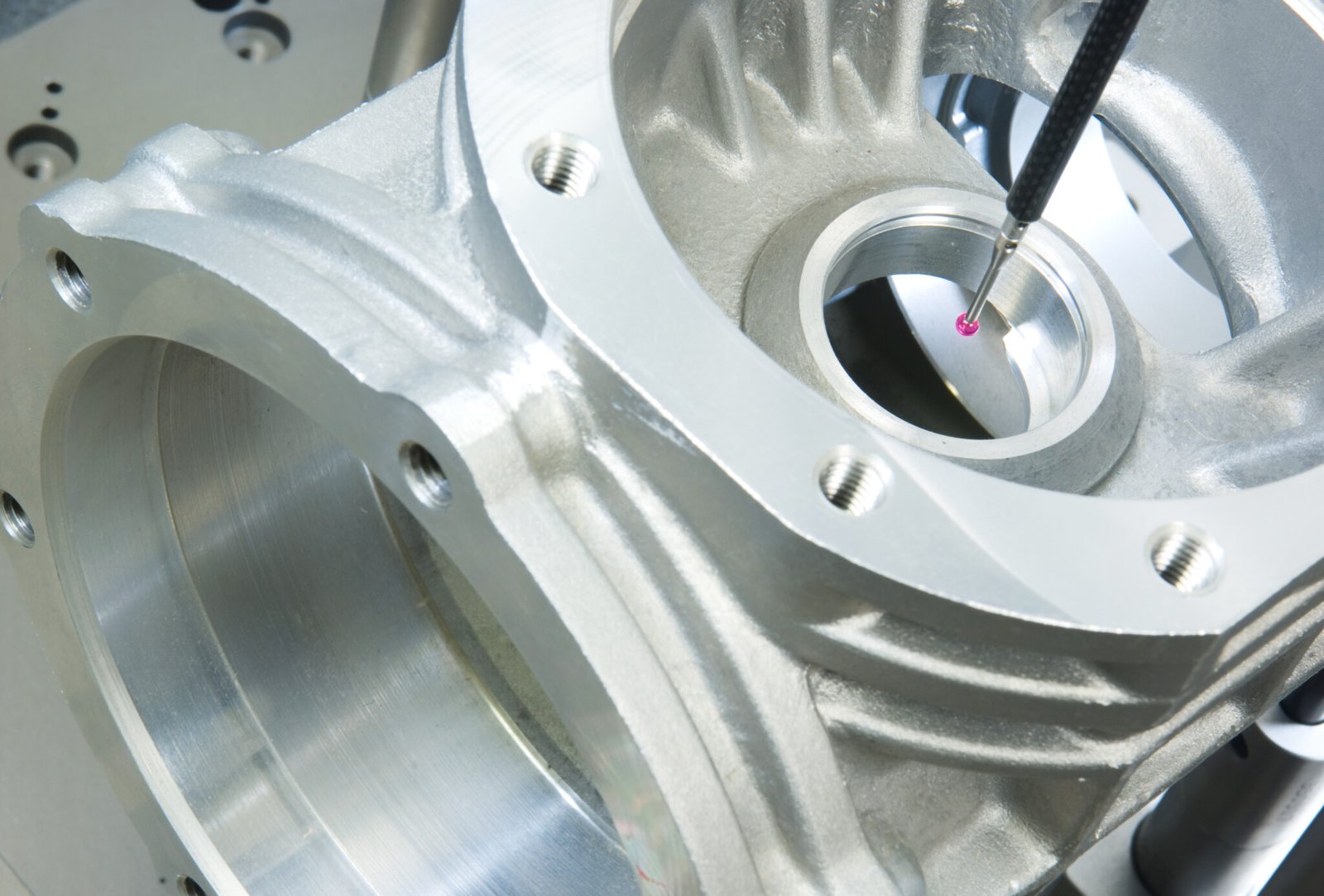

Our inspection team is composed of experienced personnel. Every dimension marked on the drawing will be inspected. Products will be shipped only after passing the inspection. Before shipping, an inspection report will be issued and sent to the customer. Inspection instruments: CMM, projector, height gauge, plug gauge, caliper, micrometer, surface roughness tester, hardness tester, etc.

Our company attaches great importance to the transportation of sailboat parts. We use professional packaging to ensure the safety of parts and select reliable transportation teams. We flexibly arrange transportation methods according to customer needs and monitor the transportation process in real time to ensure that the parts are delivered to customers on time and without damage, making customers feel at ease.

CNC machining technology plays a key role in sailboat manufacturing, offering precise component processing for various types of sailboats. Whether it’s for professional racing vessels or recreational boats, CNC machining meets diverse design and functional needs.

Racing yachts are designed for maximum speed and handling performance, often utilizing cutting-edge design and material technologies. CNC machining enables the precise fabrication of structural components such as hulls, rudders, and mast frames, ensuring stability and responsiveness at high speeds. These vessels demand meticulous attention to detail for enhanced competitiveness in races.

Sailing yachts are luxury sailboats, primarily used for leisurely cruising and vacations. They focus not only on sailing performance but also on comfort and luxury. CNC machining is crucial in the construction of sailing yachts, especially for complex designs of hulls, decks, and interiors. Through precise machining, manufacturers ensure that every component fits seamlessly, meeting the high aesthetic and functional demands of designers and clients.

Monohulls are the most traditional sailboat design, featuring a single hull, and are used for various sea conditions and sailing purposes. CNC machining provides precise hull shaping, rudder, and mast component fabrication, ensuring the best balance of stability and speed. Monohull designs often prioritize versatility, requiring highly accurate machining to ensure safety and durability.

Catamarans feature two parallel hulls, offering greater stability and space than monohulls. CNC machining is widely used in the construction of catamarans, particularly for the precise connection of the two hulls and optimization of the hull structure. CNC technology allows manufacturers to achieve lightweight materials while maintaining adequate strength and durability. The design of catamarans emphasizes comfort and stability, making them ideal for leisurely cruising and long-distance voyages.

Windsurfers are a type of watercraft that combines elements of sailing and surfing, featuring a small hull and a flexible sail. Despite their smaller size, windsurfers require high-precision CNC machining. CNC technology provides precise fabrication of structural components like masts, foot straps, and boards, ensuring flexibility and control for athletes during high-speed sailing.

CNC machining plays an indispensable role in the manufacturing of sailboat parts. Kunshan Baichuan Precision Components Co., Ltd., with its advanced equipment and exquisite technology, provides high-quality machining services for sailboat enterprises.

Maximum processing range: The company has a variety of models of CNC machine tools, among which the maximum processing range of gantry milling can reach 6500mm×4200mm×1800mm, which can meet the processing needs of large parts of sailboats, such as the manufacture of large masts, keels, etc.

Minimum machining range: The 5-axis CNC machine has a machining range of 660mm×405mm×350mm and an accuracy of up to 0.01mm, which is capable of handling some fine small parts in sailboat parts, such as small connectors, decorative parts, etc.

The company utilizes advanced CNC machining equipment, boasting exceedingly high processing accuracy. Moreover, to ensure the precision of yacht parts in terms of dimensions, the requirements for the inspection equipment are also extremely high. Some of the equipment’s accuracy can reach ±0.0005mm (such as the 2D projector SRN3020 and the 2D microscope BC – 001), meeting the stringent requirements for high precision of parts in yachts.

The yacht industry demands high levels of customization for parts. With our robust programming capabilities and flexible manufacturing processes, we can tailor yacht components based on detailed design blueprints or specific customer requirements provided. Whether it’s simple shape modifications or complex, designs, we can accurately realize these to create unique yacht parts for the industry, catering to their pursuit of performance and aesthetics in yachts.

Special surface treatment of sailboat parts is a crucial step to enhance the performance and durability of parts. In the processing flow, different surface treatment processes play their unique roles.

Through professional grinding equipment and process operations, burrs on the part surface are removed to make the surface smooth and flat. This not only enhances the aesthetic appearance of the part but also avoids stress concentration caused by burrs, ensuring the safety and stability of the part during use. In sailboat part processing, the grinding accuracy is required to be high to adapt to the usage needs of sailboats in complex marine environments.

Using high-speed sand particles to impact the part surface, creating a specific roughness on the part surface. This helps enhance the adhesion of coatings and gives the part a unique texture. For sailboat parts, sandblasting treatment can improve the corrosion resistance of the parts and make the surface easier to clean.

The part is placed in an electrolyte solution, and an oxide film is formed on the part surface through electrolysis. This oxide film can increase the hardness, wear resistance, and corrosion resistance of the part. For sailboat parts, anodizing can make them better resist the erosion of seawater and prolong the service life of the parts. At the same time, by controlling the thickness and color of the oxide film, different appearance design requirements can be met.

Depositing a layer of metal coating on the part surface by electrolysis methods, such as zinc plating, chromium plating, etc. The electroplated layer can provide a good decorative appearance and simultaneously enhance the corrosion resistance of the part. In the application of sailboat parts, electroplating can protect the parts from the erosion of seawater, moisture, and other factors. And according to different coating metals, different performance characteristics can be given to the parts. For example, chromium plating can increase the hardness and smoothness of the part surface.

Unlock rapid turnaround times for your CNC prototypes and parts. Enjoy our standard 7-day lead times. Simply upload your design to verify eligibility.

Whether it is aluminum alloy, stainless steel, or titanium alloy parts processing, our team can provide you with the best solution.

| Type | Advantage | Disadvantage |

| Ti-6AL-4V(TC4) | High strength Strength-to-weight ratio Excellent corrosion resistance Good fatigue resistance | Expensive difficult to machine limited availability |

| TA2(Grade 3) |

| Type | Advantage | Disadvantage |

| Aluminum 6061-T6 | Good machinability Corrosion resistance High strength Lightweight | Lower strength compared to some specialized alloys moderate corrosion resistance in marine environments |

Aluminum 7075-T6

| High strength Lightweight Heat treatable | Poor corrosion resistance Poor weldability |

| Aluminum 5083-H112 | Similar properties to H32 but with better weldability Good resistance to seawater | Similar to H32 Lower mechanical properties compared to heat-treated alloys |

| Type | Advantage | Disadvantage |

| Stainless steel 304 | Good corrosion resistance Ease of fabrication Cost-effective | Lower strength compared to other stainless steels Can corrode in marine environments |

| Stainless steel 316 | Excellent corrosion resistance Especially against chloride Suitable for marine environments | Higher cost compared to 304 Can be susceptible to pitting in harsh conditions |

| Stainless steel 304L | Low carbon version of 304 Improved weldability Reduced risk of carbide precipitation. | Lower strength compared to standard 304 Slightly more expensive |

| Stainless steel 316L | Low carbon version of 316 Excellent corrosion resistance Better weldability. | Higher cost compared to 304L Lower strength compared to standard 316 |

| Stainless steel 17-4ph | High strength Good corrosion resistance Can be precipitation hardened | Expensive Can be challenging to weld Needs careful heat treatment |

| Stainless steel ph13-8mo | High strength Toughness Good corrosion resistance Used in aerospace applications | Expensive Limited machinability Complex heat treatment process |

| Stainless steel SAF2205 | High resistance to stress corrosion cracking Good mechanical properties | Difficult to machine More expensive than common stainless steels |

| Type | Advantage | Disadvantage |

| Bronze | Excellent corrosion resistance Good wear resistance High strength Good castability | Higher cost Difficult to machine Prone to stress corrosion cracking |

| Brass | Corrosion resistance Easy to machine Good mechanical properties Lower cost | Lower wear resistance Susceptible to stress corrosion cracking Poor high-temperature resistance |

| Electrolytic Copper | Excellent electrical conductivity Good corrosion resistance Easy to machine | Lower strength Prone to oxidation Poor wear resistance |

| Beryllium Copper | High strength Good thermal and electrical conductivity Good wear resistance | Extremely high cost Health risks |

| Type | Advantage | Disadvantage |

| POM (DELRIN) | High stiffness Low friction Good dimensional stability Ssuitable for precision parts | Limited chemical resistance Prone to creep under high loads Not suitable for high-temperature applications |

| ABS | Good impact resistance Easy to fabricate Cost-effective | Limited UV resistance Can deform under high load Not as strong as other plastics |

| Nylon | High toughness Good abrasion resistance Can absorb moisture Suitable for mechanical parts | Absorbs moisture which can affect dimensions Limited chemical resistance, not suitable for high temperatures |

| Ultra-high-molecular-weight polyethylene (UHMWPE) | Exceptional wear resistance Low friction coefficient Corrosion resistance Impact resistance | Relatively low rigidity Limited high-temperature resistance Difficult to machine |

Provide according to the customer’s requirements.

Our company is the agent of Alnannan. Alnannan provides us with materials, and our company has advantages in terms of materials. We are equipped with material analyzers to test each batch of materials and issue material certificates to ensure that your vacuum chamber meets the requirements and has a longer service life.

The testing and assembly of sailboat parts are crucial steps to ensure the quality and performance of sailboats. The precise assembly enables each part to work closely together and exert the best performance, guaranteeing the safety and stability of the sailboat during sailing. The strict testing process can detect potential problems in advance and verify the quality and reliability of the parts. Only sailboat parts that have been accurately assembled and strictly tested can provide strong support for sailboats to sail across the ocean.

Baichuan has a 10,00-class clean room of 10,000 square meters, equipped with a wide range of quality inspection instruments: three-dimensional coordinate measuring machines, two-dimensional projectors, height gauges, micrometers, and roughness testers, etc.

| Equipment Name | Accuracy |

| Two-dimensional projector | 0.001 |

| Video measuring instrument | 0.002 |

| TESA height gauge | 0.001 |

| TRIMOS – V6 height gauge (Switzerland) | 0.0001 |

| Inside diameter micrometer (Switzerland) | 0.001 |

| Mitutoyo micrometer | 0.001 |

| Vickers hardness tester | ±1degree |

| Rockwell hardness tester | ±1degree |

| Roundness tester (Mitutoyo) | ±0.001mm |

| Coordinate measuring machine (Zeiss/ Hexagon) | 0.3μm/1.7μm |

| Roughness tester (Jingdong Digital) | Ra0.01 |

Material Strength Test

◦ Use professional equipment to apply pressure to the part materials and detect whether their bearing capacity meets the standards in complex sea conditions.

Dimensional Accuracy Detection

◦ Use high-precision measuring instruments to measure the assembled parts in all directions and strictly control the dimensional error.

Sealing Test

◦ For the parts with sealing requirements, test by simulating the seawater pressure environment to prevent seawater leakage from harming the sailboat.

Performance Test

◦ Conduct tests on the equipment simulating sailboat movement, simulate sea conditions and operating conditions to detect the actual use performance of the parts.

Parts Classification and Sorting: According to the design drawings, carefully classify and accurately sort the sailboat parts to ensure the parts are prepared correctly.

Precise Docking and Installation: Use professional tools and fixtures to install the fine components step by step starting from the basic framework, strictly follow the established installation sequence and process specifications, and carefully check after each installation step; For key connection parts, adopt advanced fastening technologies to ensure stable connection.

1. Keep Parts Clean: During assembly, strictly ensure the parts are clean to avoid impurities affecting the fitting accuracy and service life.

2. Operator Requirements: Operators need to be experienced, professionally skilled, and operate strictly according to specifications, paying attention to details.

3. Consider Material Characteristics: Consider factors such as thermal expansion and contraction of parts of different materials, and reserve appropriate tolerance ranges to adapt to the operation of sailboats in different environments.

Discover unmatched precision, top-tier quality, and unmatched affordability, no matter the volume. BaiChuan Precision stands ready to meet your needs with speed and expertise.

1 pcs

Get Factory Price Directly

Prototyping 3 Day

7/24 Personalized Collaboration & Strategic DFM Guidance

ISO 9001:2015, provides a QC report for each part

3-, 4-, & 5-axis CNC machines for manufacturing. CMM & XRF analyzer for QC

The transportation of sailboat components is a crucial part of our service, and we are dedicated to providing our clients with safe and efficient freight solutions.

Dive into the testimonials of our valued partners to discover how we’ve met their unique needs with precision and excellence.

I found the company through Google. Our first collaboration was just a sample order, but they did an exceptionally good job, so we continued to work with them for several years. Our orders are usually diverse and not very large, which might not be very attractive to some big companies, but they always provide excellent service with enthusiasm. Whether it's quality or delivery time, they perform exceptionally well, and their prices are very reasonable. I definitely plan to continue working with them.

Sarah Thompson

In unserer Branche benötigen wir häufig spezielle Stahlsorten wie TC4 und 17-4PH. Bai Chuan stellt uns jedes Mal rechtzeitig Materialzertifikate und Videos von vor Ort durchgeführten Spektrumanalysen zur Verfügung, was unseren Kunden viel Vertrauen und Zufriedenheit gibt. Die Bearbeitungsgeschwindigkeit ist sehr hoch, und die Arbeiter arbeiten sehr effizient. Im Vergleich zu lokalen Anbietern ist Bai Chuan in Bezug auf das Preis-Leistungs-Verhältnis deutlich überlegen. Ich danke Bai Chuan sehr für den hervorragenden Service, den sie stets bieten!

Hans Müller

Normally, we will provide a quote within 12 hours. If the information you provide is comprehensive, it will allow us to quote you faster.

CAD Files in Any Format: Whether it’s 2D or 3D, we accept STP, IGES, X_T, DWG, PDF, STL, ensuring no design is too complex for us to handle.

Project Specifics: Share your expected quantities, desired machining processes, and material requirements to help us tailor our services perfectly to your needs.

Finishing Touches: Specify any secondary operations such as finishing details, heat treatments, anodizing, or plating to ensure your parts meet the highest standards.

Compliance and Certifications: Let us know about any critical industry standards or customer specifications you adhere to, including First Article Inspection, PPAP requirements, and necessary certifications.

Additional Insights: Any target pricing, desired lead times, or other pertinent information will help us align our services with your expectations.

That’s not a problem. Just send us the photos of each angle, tell us the overall dimesions, material, surface treatment and QTY of the sample, and we will quote an approximate price. If you think the price is right, we then make samples based on the drawings we get and adjust them to perfection.

As an ISO-9001 certified factory, we will strictly follow the tolerance requirements on your drawings. If you don’t know the specific tolerances, you can provide matching products or tools for us to test. Our QC department is equipped with 2 CMMs and dozens of different types of testing instruments, and will provide testing reports for each part.

With a sprawling 5000-square-meter machining shop. Our setup is not just vast; it’s meticulously organized and equipped with 30+ high-performance CNC machines and our team of 50+ skilled professionals which operates 24/7. This relentless work ethic ensures we can deliver over 500 machining projects and more than 30,000 machined parts per month, keeping your projects on schedule every time.

Milling: 6500*4200*1800mm

Lathe: 1600*1400mm

Checking: CMM 4000*2000*1500mm

You can download our equipment list here to know the details.

Technical Consultation

Repair and Replacement

Regular Return Visits

Embark on a seamless CNC machining experience with BaiChuan Precision, where your prototypes evolve into production with unmatched quality, speed, and cost-efficiency.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.