Welcome to Baichuan, your premier partner for precision-engineered vacuum chambers in the semiconductor, photovoltaic, and scientific research industries. We blend cutting-edge technology with unparalleled expertise to deliver vacuum chambers that set industry standards.

Secure, confidential uploads. Your designs are safe with us.

Baichuan Precision, with over 18 years of excellence, is at the forefront of delivering customized vacuum chamber solutions. Our factory, equipped with over 30 state-of-the-art machines, stands as a testament to our commitment to quality and innovation. Recognized globally, we proudly serve industries in the United States, Canada, Germany, Japan, Korea, the Netherlands, and the UK. At Baichuan Precision, we bridge the gap between ambitious engineering and real-world applications, ensuring each vacuum chamber we produce meets the highest standards of efficiency and durability.

Navigating the intricacies of customized vacuum chambers can be complex, so we’ve assembled a comprehensive guide for you to explore. To ensure you swiftly find the details you’re after, we’ve crafted a convenient content directory below. Clicking on any section will instantly take you to the relevant information.

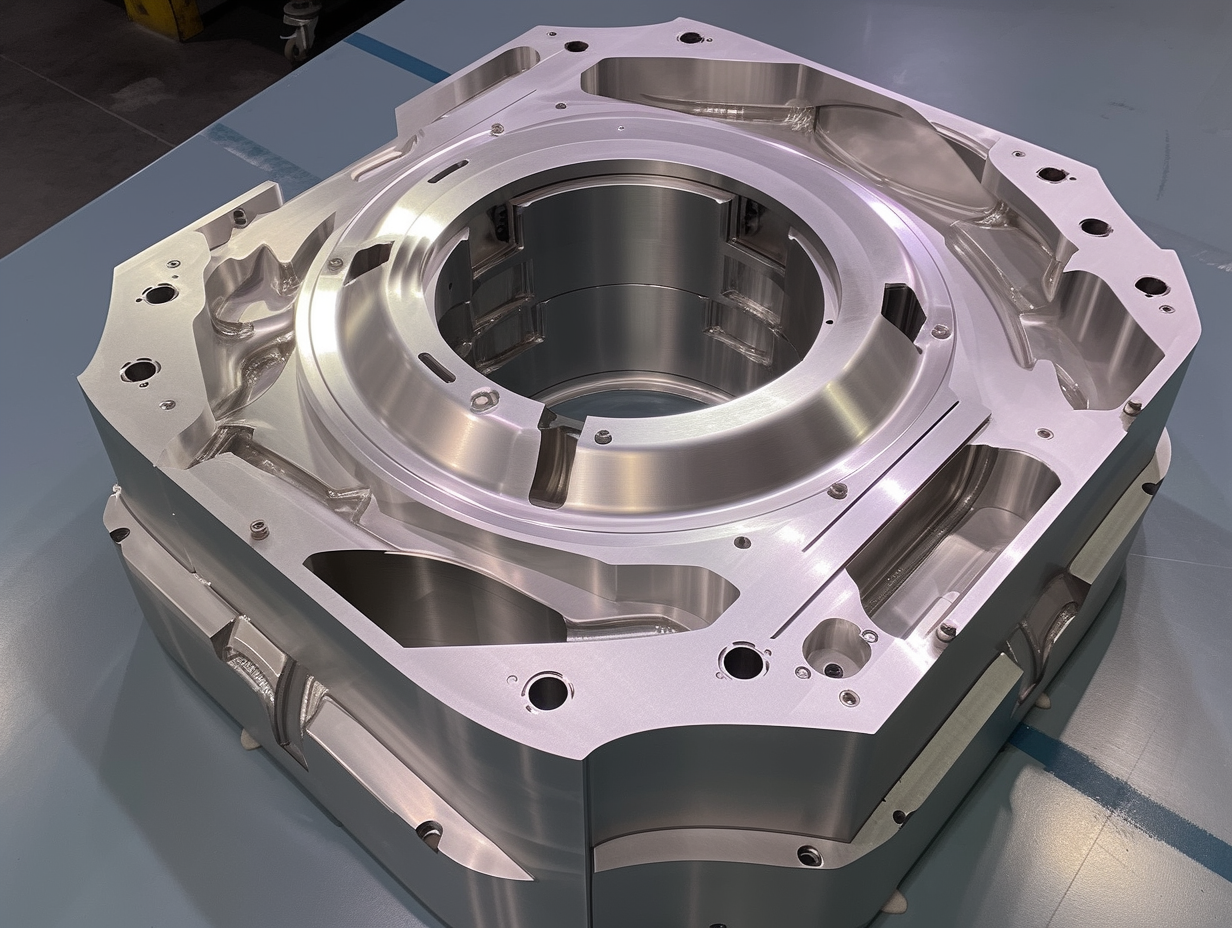

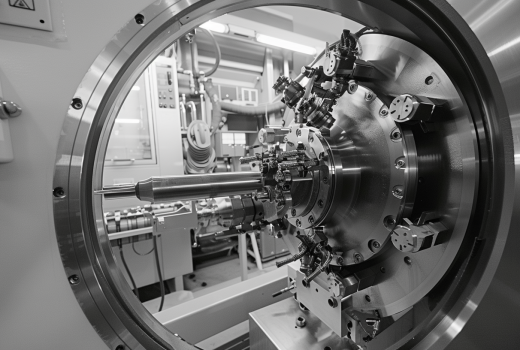

Whether it is stainless steel, aluminum, or titanium alloys, high vacuum chambers, and ultra-high vacuum chambers, or one-piece or welded chambers, from regular sizes to oversized products, we can meet any of your vacuum chamber requirements. We are equipped with a super-large CNC gantry machining center with a maximum stroke of 6500*4200*1800mm so that your design and products are no longer limited by processing capabilities and realize your higher pursuit of vacuum chambers.

We have a professional welding team led by former welding engineers from Applied Materials, who are proficient in various welding technologies for vacuum chambers, such as brazing, EBW, laser welding, argon arc welding, vacuum brazing, vacuum diffusion welding, and orbital welding. Different welding types correspond to different materials such as aluminum, stainless steel, and titanium, and your various requirements for vacuum chamber welding.

Friction Stir Welding (FSW) is an innovative and solid-state joining process. This technique is primarily used to join materials that are difficult to weld by traditional fusion methods, especially aluminum and other non-ferrous metals, though it has been successfully applied to steels, titanium, and even thermoplastics. We are proud to introduce to you our Asia-leading friction stir welding capabilities. The welding depth can reach 80-100mm.

Welding is fundamental to the construction, integrity, and functionality of vacuum chambers, ensuring they meet the stringent requirements of their intended applications. Welding plays a crucial role in the manufacturing and maintenance of vacuum chambers for several reasons.

Airtight Seals: The primary function of a vacuum chamber is to maintain a vacuum or a controlled atmosphere inside the chamber. Welding is essential for creating airtight seals that prevent air or gases from leaking into or out of the chamber. This ensures that the vacuum integrity is maintained, which is critical for the processes that the chamber is used for, such as in scientific research, aerospace, and semiconductor manufacturing.

Strength and Durability: Vacuum chambers need to withstand internal pressure differentials without deforming or breaking. Welding provides strong joins that can handle these stresses over the chamber’s operational life. This structural integrity is vital, especially for chambers used in high-pressure, high-temperature, or corrosive environments.

Material Compatibility: Vacuum chambers are often made from metals like stainless steel, aluminum, or titanium, which have low outgassing rates—a critical property for maintaining vacuum integrity. Welding techniques for these materials have been developed to ensure that the welds themselves do not become sources of gas leak or contamination.

Complex Shapes and Customization: Welding allows for the construction of chambers with complex shapes or custom configurations. This is important for scientific experiments or industrial processes that require unique chamber designs to accommodate specific equipment, samples, or processes.

Repair and Modification: Over time, vacuum chambers may require repair due to wear and tear or might need modifications to suit new processes or equipment. Welding is a versatile method that can be used for both repairing damages (like cracks or leaks) and making modifications (like adding new ports or changing the chamber size).

Minimizing Contamination: Proper welding techniques minimize the risk of contamination inside the chamber, which is crucial for processes that require high purity environments, such as semiconductor manufacturing or material science experiments.

Characteristics

Pressure Range:

Material Requirements: Materials used in HV and UHV systems must have low outgassing rates to minimize contamination and pressure increases. Common materials include stainless steel, aluminum, and ceramics. Surfaces are often electropolished to reduce gas absorption and desorption.

Sealing Techniques: Seals must prevent any air leakage into the vacuum. Metal seals are often preferred in UHV systems due to their lower outgassing rates compared to elastomeric seals.

Vacuum Pumps: Different types of vacuum pumps are used, often in combinations, to achieve and maintain the required vacuum levels. Turbomolecular and ion pumps are common in UHV applications, whereas rotary vane and diffusion pumps might be seen in HV setups.

Vacuum Measurement: Accurate measurement is critical. Ionization gauges are typically used in UHV conditions because of their sensitivity to extremely low pressures.

Application Scope

Semiconductor Manufacturing: HV and UHV environments are essential for semiconductor fabrication to prevent contamination that could lead to defects in microchips.

Surface Science: Studies involving the physical and chemical properties of surfaces often require UHV conditions to prevent contamination and to allow for the accurate measurement of surface interactions.

Particle Accelerators: Both HV and UHV are used in the operation of particle accelerators to minimize interactions between the particles and any residual gases, which can affect the quality of the experimental results.

Space Simulation Chambers: HV and UHV chambers are used to simulate the vacuum of space to test spacecraft components and sensors under conditions similar to those they will experience in orbit.

Nanotechnology: The fabrication and study of nanoscale materials and devices often require UHV conditions to ensure surface purity and to enable precise manipulation of atoms and molecules.

Electron Microscopy: UHV is crucial in some types of electron microscopes, which require vacuum conditions to prevent air molecules from interfering with the electron beam used to image samples.

Synchrotron Radiation Facilities: UHV conditions are necessary in these facilities to prevent the absorption or scattering of the generated synchrotron radiation by air molecules.

Characteristics:

Application Scope:

Characteristics:

Application Scope:

Characteristics:

Application Scope:

Characteristics:

Application Scope:

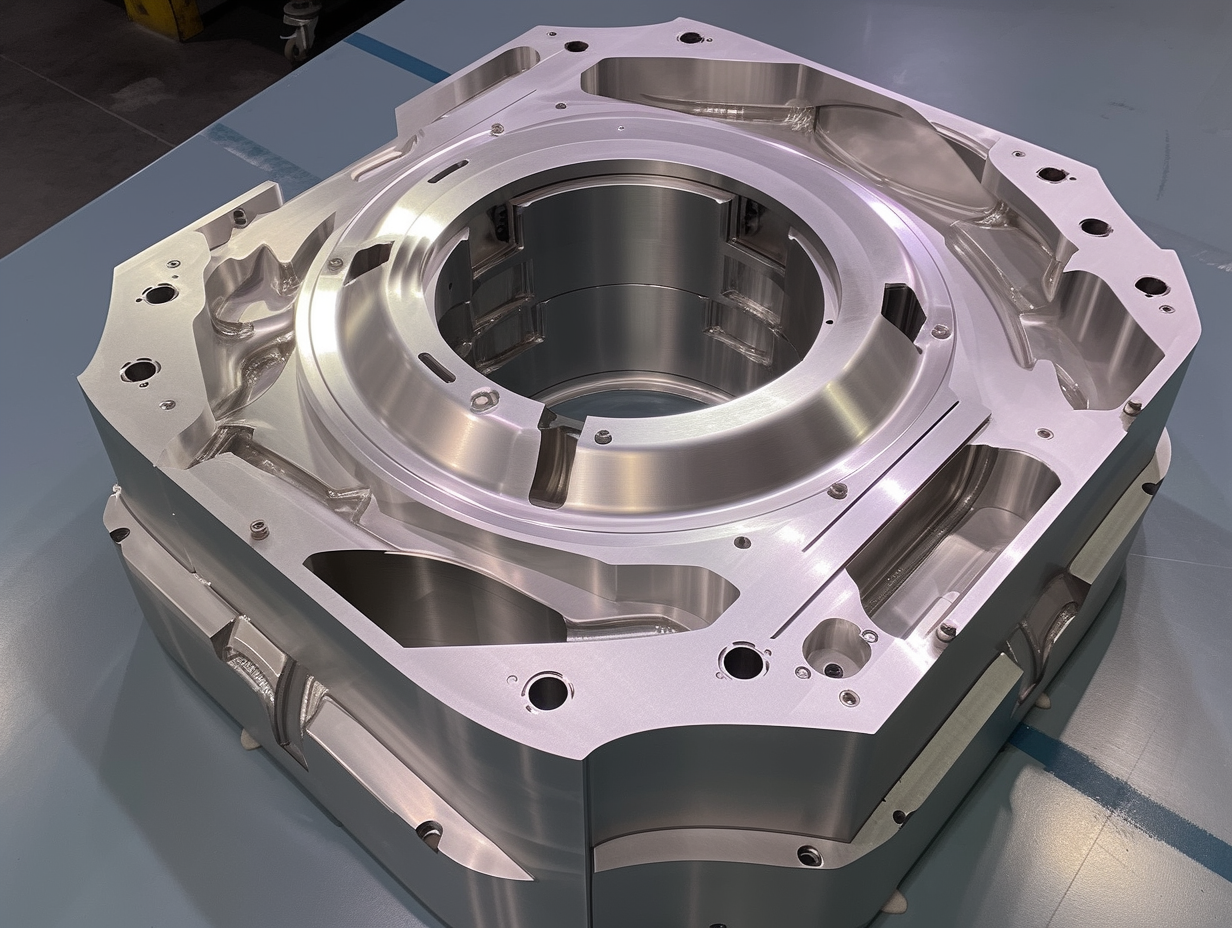

Discover the Zenith of Customization with BaiChuan Precision: Your Partner in Innovation. Dive into a world where your concepts materialize with unparalleled precision, thanks to our advanced vacuum chamber fabrication. Our portfolio shines with examples of our commitment to excellence, offering bespoke vacuum chambers meticulously engineered by our adept craftsmen. For those seeking the ultimate in vacuum chamber customization, BaiChuan Precision marks the end of your quest. Join us, and let’s shape the future together.

Choosing Baichuan means partnering with a company that not only boasts a robust manufacturing capability and cutting-edge technology but also possesses a deep understanding of the industries we serve.

Dive into the testimonials of our valued partners to discover how we’ve met their unique needs with precision and excellence.

As the owner of a small business that develops new products for our own market and also for other companies, BC has always been very helpful as our main supplier of prototype parts from metals and plastics. For 5-6 years we have relied on BC for various prototypes for a multitude of products made from steel, aluminium, and several plastics. BC are receptive to our needs and are able to source the correct material for customised applications, such as specific grades of non-magnetic stainless steel. BC have also been our partner for manufacturing of stainless steel components for our electric bike business and polycarbonate parts for our drilling alignment monitor, as well as many other productions from a wide variety of products across multiple industries.

Sam Sewell

Bonjour je m'appelle Mickaël, je voulais faire une petite vidéo pour parler de mes retours avec la société Kunshan Baichuan Precision. Si je dois décrire en quelques mots, je dirais: attentif,très impliqué, travail de précision, réactivité et communication aisée. J'ajouterai un grand merci à mon interlocutrice Linda qui a été un soutien et une patience sans faille. Merci.

Mickaël Lauriola

Unlock rapid turnaround times for your vacuum chambers. Enjoy our standard 7-day lead times. Simply upload your design to verify eligibility.

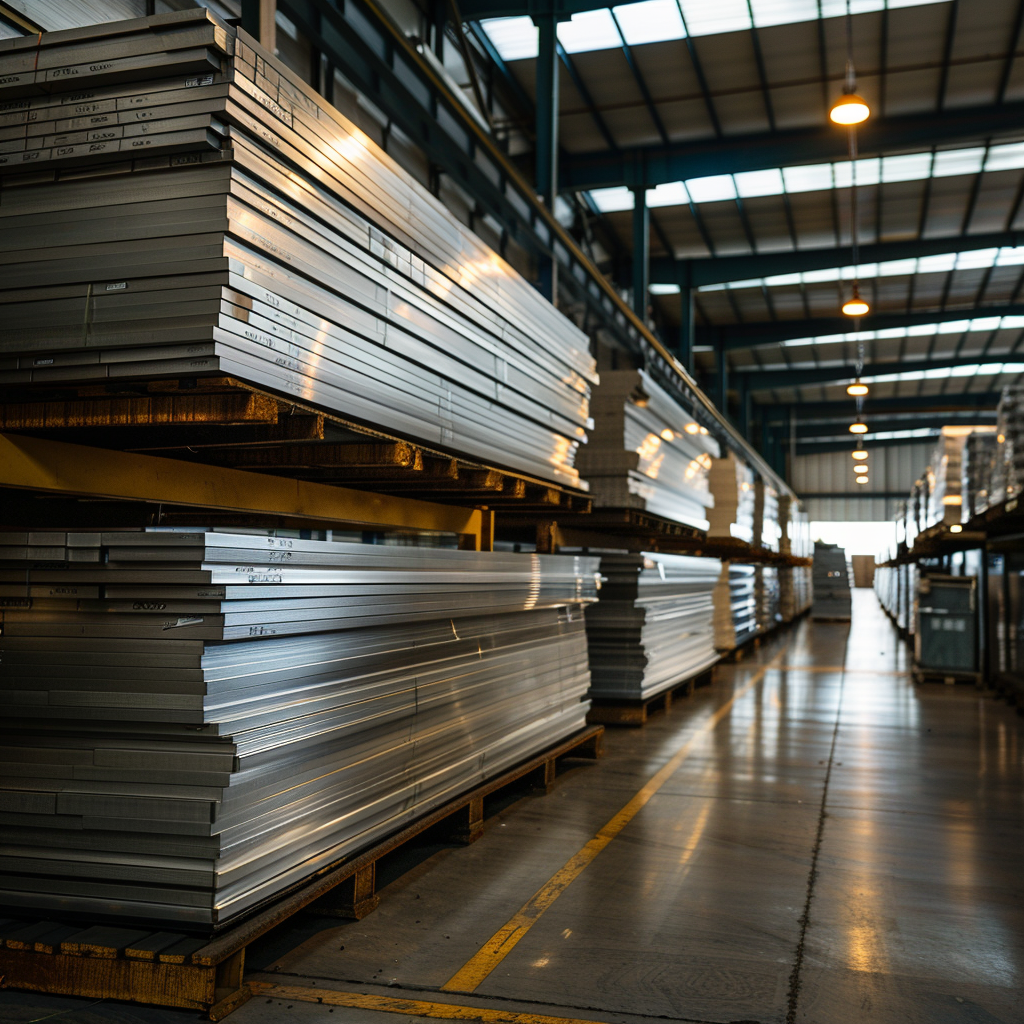

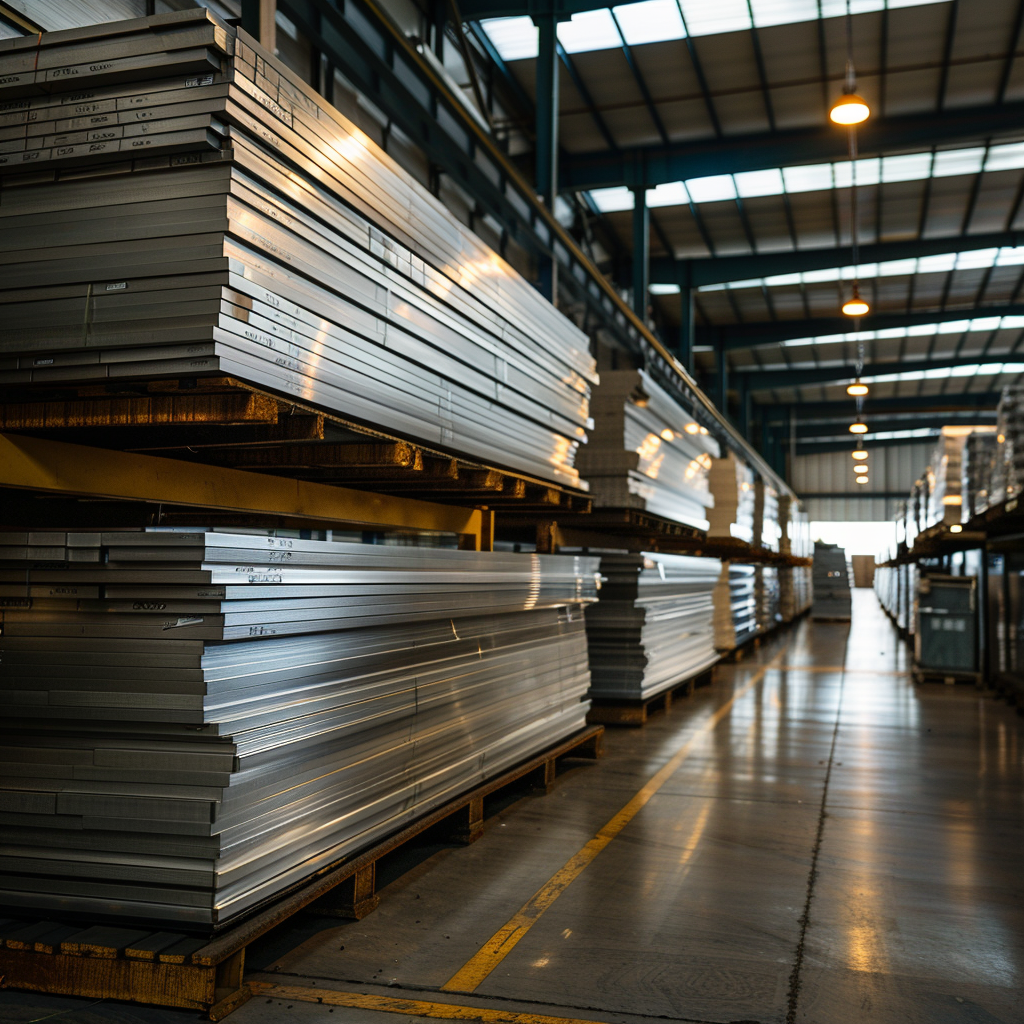

Have you ever encountered defects in your vacuum chamber due to product materials not meeting requirements? Our warehouses in Chengdu and Shanghai can provide more than 2,000 tons of spot aluminum and stainless steel materials to meet the various sizes required for processing vacuum chambers, especially materials for large vacuum chambers. We are equipped with material analyzers to test each batch of materials and issue material certificates to ensure that your vacuum chamber meets the requirements and has a longer service life.

Vacuum chambers are essential components in many industrial and research applications, including semiconductor manufacturing, materials science research, and space simulation tests. The choice of material for a vacuum chamber is crucial and depends on the specific requirements of the application, such as vacuum level, chemical resistance, mechanical properties, and cost.

Preferred for its lightweight, thermal conductivity, and cost-effectiveness but is less suitable for chemically aggressive or ultra-high vacuum applications.

Offers an excellent balance of durability, corrosion resistance, and low outgassing, making it a versatile choice for a wide range of vacuum applications.

Stand out for their superior strength-to-weight ratio and exceptional corrosion resistance, ideal for specialized applications where these properties are critical, albeit at a higher cost.

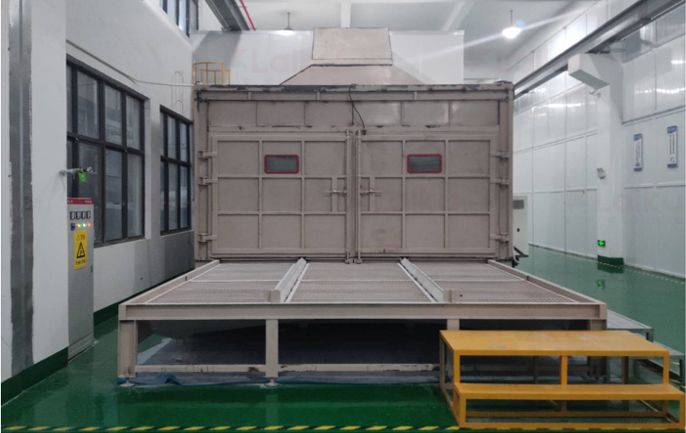

Cleaning the vacuum chamber is essential for several reasons, particularly when dealing with high vacuum (HV) and ultra-high vacuum (UHV) systems, where even minute amounts of contaminants can significantly impact the system’s performance. We are equipped with a professional cleaning workshop to remove impurities and oil stains on the surface of the newly completed vacuum chamber. This kind of cleaning cannot be judged by the naked eye.

Choose from our range of expertly applied finishes: Glass Bead Blasted, Machine Polished, Sandblasted, and Electropolished. Our standard offerings include flanges and precision machined components with a flawless 32-microinch surface finish, and an ultra-refined 16-microinch finish on sealing surfaces. Need even more precision? Consult with our design engineers for bespoke solutions tailored to your exact specifications.

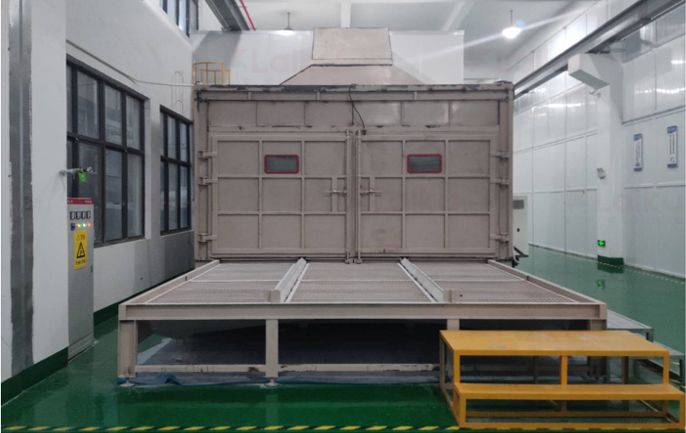

Welcome to our state-of-the-art purification workshop! Carefully designed to ensure an ultra-clean environment, which is critical to minimizing contamination in sensitive manufacturing processes.

Our Class 10000 cleanrooms contain fewer than 352,000 particles larger than 0.5 microns per cubic foot of air, an important criterion for the high standards our industry requires. This specialized environment allows us to inspect, assemble and package critical components under the strictest standards of cleanliness and control, ensuring the highest quality and reliability of our products.

The workshop includes advanced air filtration systems, tightly controlled humidity and temperature conditions, and sophisticated static and contamination control measures. Each area within the shop is designed to optimize a specific aspect of our production process, from initial assembly to final inspection, ensuring every component meets our and our discerning customers’ exacting standards.

In the regular dimensional inspection steps, we first conduct on-machine inspection during product processing and as soon as possible after processing is completed. Then, the finished product is transferred to our CMM machine for secondary dimensional inspection. The CMM equipped with a maximum inspection range of 4000 mm allows us to inspect almost all products. At the same time, each product corresponds to a test report, which you can view at any time.

For specializing in high-precision manufacturing for the semiconductor industry, employing rigorous leak testing procedures is essential for maintaining our reputation as a provider of high-quality components. Our advanced testing facilities, including helium mass spectrometers and ultrasonic detectors, ensure that every vacuum chamber meets the strictest standards required by their clients.

Vacuum packing is a critical process in various industries, from food and beverage to electronics and pharmaceuticals. This packaging method involves removing air from the package before sealing it, significantly reducing the oxygen level inside. This reduction in oxygen helps prolong the shelf life of products, maintaining quality, and protecting against external elements.

At BaiChuan Precision, we’re more than suppliers—we’re your precision partners. Specializing in custom CNC machined vacuum chambers, we serve critical industries like semiconductors, photovoltaics, and PVD/CVD coatings. With over 18 years of expertise and advanced machinery, we ensure top-quality, precisely tailored solutions for your projects.

Deposition (e.g., physical vapor deposition, chemical vapor deposition), etching, and lithography. These processes require controlled environments to ensure high purity and precision in the layering and patterning of materials on silicon wafers.

In pharmaceutical manufacturing, vacuum chambers are used for freeze-drying (lyophilization) to remove moisture from substances, improving the stability and shelf life of pharmaceutical products without using heat, which could degrade the product.

Researchers use vacuum chambers to study the properties of materials under low-pressure conditions, which can reveal different behaviors and properties than at atmospheric pressure.

Simulate the vacuum of space to test spacecraft components and satellites, ensuring they can withstand the conditions they will face in orbit, including extreme temperatures and the absence of atmospheric pressure.

Used for applying thin films of materials onto substrates through techniques like sputtering or evaporation(PVD, CVD, FPD). This is critical in creating coatings for optics, electronics, and wear-resistant materials.

Vacuum chambers are used to remove gases from materials like plastics and resins used in automotive parts. This process helps in reducing defects and improving the quality and strength of the materials.

Vacuum chambers are typically constructed from materials that are non-outgassing and have low vapor pressures to maintain a stable vacuum environment. Common materials include:

The most popular material for vacuum chamber is stainless steel. Especially 304 stainless steel is extensively utilized in the construction of vacuum chambers due to its high strength and suitability for wide temperature variations. It resists oxidation effectively and can be joined through welding or brazing.

We manufacture a wide range of vacuum chambers to suit various applications and industries:

Yes, we specialize in customizing vacuum chambers to meet specific client requirements. Whether you need specific dimensions, port configurations, feedthroughs, or specialized coatings, we can tailor our products to suit your exact needs. Our engineering team works closely with clients to ensure that all specifications are met.

Absolutely. We offer comprehensive support and service packages for installation, maintenance, and repair of vacuum chambers. Our team is available to assist with on-site installations and provide training for your staff on operation and maintenance procedures.

Lead times can vary based on the complexity and customization of the chamber. Generally, custom orders may take 4-10 weeks. We always work to meet our client’s timeline and provide accurate estimates during the initial consultation.

CAD Files in Any Format: Whether it’s 2D or 3D, we accept STP, IGES, X_T, DWG, PDF, STL, ensuring no design is too complex for us to handle.

Project Specifics: Share your expected quantities, desired machining processes, and material requirements to help us tailor our services perfectly to your needs.

Finishing Touches: Specify any secondary operations such as finishing details, heat treatments, anodizing, or plating to ensure your parts meet the highest standards.

Compliance and Certifications: Let us know about any critical industry standards or customer specifications you adhere to, including First Article Inspection, PPAP requirements, and necessary certifications.

Additional Insights: Any target pricing, desired lead times, or other pertinent information will help us align our services with your expectations.

As a company established in 2006, we deeply understand the importance of integrity, and protecting the privacy of our customers is something we take extremely seriously. We can sign a NDA(non-disclosure agreements) before receiving your drawings, so please feel free to leave your design to us!

That’s not a problem. Just send us the photos of each angle, tell us the overall dimesions, material, surface treatment and QTY of the sample, and we will quote an approximate price. If you think the price is right, we then make samples based on the drawings we get and adjust them to perfection.

Quality assurance is integral to our manufacturing process. We employ several quality control measures including:

A vacuum chamber is an enclosed space from which air and other gases are removed using a vacuum pump, creating a low-pressure environment inside the chamber, commonly referred to as a vacuum. The degree of vacuum refers to how closely the chamber approaches a perfect vacuum, where no particles of matter exist.

Vacuum chambers can be categorized based on the level of vacuum they achieve, their design, and the specific applications they are used for. The differences often revolve around the construction materials, the technology used to create the vacuum and the ultimate purpose of the chamber. Here’s a breakdown of the different types of vacuum chambers:

1. Based on Vacuum Levels

2. Based on Design and Material

3. Based on Specific Applications

Vacuum chambers require a variety of accessories to function efficiently and to enable specific tasks within the vacuum environment. Here are some of the most commonly used accessories for vacuum chambers:

1. Vacuum Pumps

2. Vacuum Gauges

3. Feedthroughs

4. Valves and Flanges

5. Heaters and Temperature Controllers

6. Mass Spectrometers and Residual Gas Analyzers

7. Chamber Shrouds

8. Manipulators and Sample Holders

9. Baffle Plates and Traps

10. Cleaning and Maintenance Tools

Whether it is stainless steel, aluminum, or titanium alloys, high vacuum chambers, and ultra-high vacuum chambers, or one-piece or welded chambers, from regular sizes to oversized products, we can meet any of your vacuum chamber requirements. We are equipped with a super-large CNC gantry machining center with a maximum stroke of 6500*4200*1800mm so that your design and products are no longer limited by processing capabilities and realize your higher pursuit of vacuum chambers.

We have a professional welding team led by former welding engineers from Applied Materials, who are proficient in various welding technologies for vacuum chambers, such as brazing, EBW, laser welding, argon arc welding, vacuum brazing, vacuum diffusion welding, and orbital welding. Different welding types correspond to different materials such as aluminum, stainless steel, and titanium, and your various requirements for vacuum chamber welding.

Friction Stir Welding (FSW) is an innovative and solid-state joining process. This technique is primarily used to join materials that are difficult to weld by traditional fusion methods, especially aluminum and other non-ferrous metals, though it has been successfully applied to steels, titanium, and even thermoplastics. We are proud to introduce to you our Asia-leading friction stir welding capabilities. The welding depth can reach 80-100mm.

Airtight Seals: The primary function of a vacuum chamber is to maintain a vacuum or a controlled atmosphere inside the chamber. Welding is essential for creating airtight seals that prevent air or gases from leaking into or out of the chamber. This ensures that the vacuum integrity is maintained, which is critical for the processes that the chamber is used for, such as in scientific research, aerospace, and semiconductor manufacturing.

Strength and Durability: Vacuum chambers need to withstand internal pressure differentials without deforming or breaking. Welding provides strong joins that can handle these stresses over the chamber’s operational life. This structural integrity is vital, especially for chambers used in high-pressure, high-temperature, or corrosive environments.

Material Compatibility: Vacuum chambers are often made from metals like stainless steel, aluminum, or titanium, which have low outgassing rates—a critical property for maintaining vacuum integrity. Welding techniques for these materials have been developed to ensure that the welds themselves do not become sources of gas leak or contamination.

Complex Shapes and Customization: Welding allows for the construction of chambers with complex shapes or custom configurations. This is important for scientific experiments or industrial processes that require unique chamber designs to accommodate specific equipment, samples, or processes.

Repair and Modification: Over time, vacuum chambers may require repair due to wear and tear or might need modifications to suit new processes or equipment. Welding is a versatile method that can be used for both repairing damages (like cracks or leaks) and making modifications (like adding new ports or changing the chamber size).

Minimizing Contamination: Proper welding techniques minimize the risk of contamination inside the chamber, which is crucial for processes that require high-purity environments, such as semiconductor manufacturing or material science experiments.

Characteristics

Pressure Range:

Material Requirements: Materials used in HV and UHV systems must have low outgassing rates to minimize contamination and pressure increases. Common materials include stainless steel, aluminum, and ceramics. Surfaces are often electropolished to reduce gas absorption and desorption.

Sealing Techniques: Seals must prevent any air leakage into the vacuum. Metal seals are often preferred in UHV systems due to their lower outgassing rates compared to elastomeric seals.

Vacuum Pumps: Different types of vacuum pumps are used, often in combinations, to achieve and maintain the required vacuum levels. Turbomolecular and ion pumps are common in UHV applications, whereas rotary vane and diffusion pumps might be seen in HV setups.

Vacuum Measurement: Accurate measurement is critical. Ionization gauges are typically used in UHV conditions because of their sensitivity to extremely low pressures.

Application Scope

Semiconductor Manufacturing: HV and UHV environments are essential for semiconductor fabrication to prevent contamination that could lead to defects in microchips.

Surface Science: Studies involving the physical and chemical properties of surfaces often require UHV conditions to prevent contamination and to allow for the accurate measurement of surface interactions.

Particle Accelerators: Both HV and UHV are used in the operation of particle accelerators to minimize interactions between the particles and any residual gases, which can affect the quality of the experimental results.

Space Simulation Chambers: HV and UHV chambers are used to simulate the vacuum of space to test spacecraft components and sensors under conditions similar to those they will experience in orbit.

Nanotechnology: The fabrication and study of nanoscale materials and devices often require UHV conditions to ensure surface purity and to enable precise manipulation of atoms and molecules.

Electron Microscopy: UHV is crucial in some types of electron microscopes, which require vacuum conditions to prevent air molecules from interfering with the electron beam used to image samples.

Synchrotron Radiation Facilities: UHV conditions are necessary in these facilities to prevent the absorption or scattering of the generated synchrotron radiation by air molecules.

Characteristics:

Application Scope:

Characteristics:

Application Scope:

Characteristics:

Application Scope:

Choosing Baichuan means partnering with a company that not only boasts a robust manufacturing capability and cutting-edge technology but also possesses a deep understanding of the industries we serve.

Have you ever encountered defects in your vacuum chamber due to product materials not meeting requirements? Our warehouses in Chengdu and Shanghai can provide more than 2,000 tons of spot aluminum and stainless steel materials to meet the various sizes required for processing vacuum chambers, especially materials for large vacuum chambers. We are equipped with material analyzers to test each batch of materials and issue material certificates to ensure that your vacuum chamber meets the requirements and has a longer service life.

Vacuum chambers are essential components in many industrial and research applications, including semiconductor manufacturing, materials science research, and space simulation tests. The choice of material for a vacuum chamber is crucial and depends on the specific requirements of the application, such as vacuum level, chemical resistance, mechanical properties, and cost.

Preferred for its lightweight, thermal conductivity, and cost-effectiveness but is less suitable for chemically aggressive or ultra-high vacuum applications.

Offers an excellent balance of durability, corrosion resistance, and low outgassing, making it a versatile choice for a wide range of vacuum applications.

Stand out for their superior strength-to-weight ratio and exceptional corrosion resistance, ideal for specialized applications where these properties are critical, albeit at a higher cost.

Cleaning the vacuum chamber is essential for several reasons, particularly when dealing with high vacuum (HV) and ultra-high vacuum (UHV) systems, where even minute amounts of contaminants can significantly impact the system’s performance. We are equipped with a professional cleaning workshop to remove impurities and oil stains on the surface of the newly completed vacuum chamber. This kind of cleaning cannot be judged by the naked eye.

Choose from our range of expertly applied finishes: Glass Bead Blasted, Machine Polished, Sandblasted, and Electropolished. Our standard offerings include flanges and precision machined components with a flawless 32-microinch surface finish, and an ultra-refined 16-microinch finish on sealing surfaces. Need even more precision? Consult with our design engineers for bespoke solutions tailored to your exact specifications.

Welcome to our state-of-the-art purification workshop! Carefully designed to ensure an ultra-clean environment, which is critical to minimizing contamination in sensitive manufacturing processes.

Our Class 10000 cleanrooms contain fewer than 352,000 particles larger than 0.5 microns per cubic foot of air, an important criterion for the high standards our industry requires. This specialized environment allows us to inspect, assemble and package critical components under the strictest standards of cleanliness and control, ensuring the highest quality and reliability of our products.

The workshop includes advanced air filtration systems, tightly controlled humidity and temperature conditions, and sophisticated static and contamination control measures. Each area within the shop is designed to optimize a specific aspect of our production process, from initial assembly to final inspection, ensuring every component meets our and our discerning customers’ exacting standards.

In the regular dimensional inspection steps, we first conduct on-machine inspection during product processing and as soon as possible after processing is completed. Then, the finished product is transferred to our CMM machine for secondary dimensional inspection. The CMM equipped with a maximum inspection range of 4000 mm allows us to inspect almost all products. At the same time, each product corresponds to a test report, which you can view at any time.

For specializing in high-precision manufacturing for the semiconductor industry, employing rigorous leak testing procedures is essential for maintaining our reputation as a provider of high-quality components. Our advanced testing facilities, including helium mass spectrometers and ultrasonic detectors, ensure that every vacuum chamber meets the strictest standards required by their clients.

Vacuum packing is a critical process in various industries, from food and beverage to electronics and pharmaceuticals. This packaging method involves removing air from the package before sealing it, significantly reducing the oxygen level inside. This reduction in oxygen helps prolong the shelf life of products, maintaining quality, and protecting against external elements.

Deposition (e.g., physical vapor deposition, chemical vapor deposition), etching, and lithography. These processes require controlled environments to ensure high purity and precision in the layering and patterning of materials on silicon wafers.

In pharmaceutical manufacturing, vacuum chambers are used for freeze-drying (lyophilization) to remove moisture from substances, improving the stability and shelf life of pharmaceutical products without using heat, which could degrade the product.

Researchers use vacuum chambers to study the properties of materials under low-pressure conditions, which can reveal different behaviors and properties than at atmospheric pressure.

Simulate the vacuum of space to test spacecraft components and satellites, ensuring they can withstand the conditions they will face in orbit, including extreme temperatures and the absence of atmospheric pressure.

Used for applying thin films of materials onto substrates through techniques like sputtering or evaporation(PVD, CVD, FPD). This is critical in creating coatings for optics, electronics, and wear-resistant materials.

Vacuum chambers are used to remove gases from materials like plastics and resins used in automotive parts. This process helps in reducing defects and improving the quality and strength of the materials.

Vacuum chambers are typically constructed from materials that are non-outgassing and have low vapor pressures to maintain a stable vacuum environment. Common materials include:

The most popular material for vacuum chamber is stainless steel. Especially 304 stainless steel is extensively utilized in the construction of vacuum chambers due to its high strength and suitability for wide temperature variations. It resists oxidation effectively and can be joined through welding or brazing.

We manufacture a wide range of vacuum chambers to suit various applications and industries:

Yes, we specialize in customizing vacuum chambers to meet specific client requirements. Whether you need specific dimensions, port configurations, feedthroughs, or specialized coatings, we can tailor our products to suit your exact needs. Our engineering team works closely with clients to ensure that all specifications are met.

Absolutely. We offer comprehensive support and service packages for installation, maintenance, and repair of vacuum chambers. Our team is available to assist with on-site installations and provide training for your staff on operation and maintenance procedures.

Lead times can vary based on the complexity and customization of the chamber. Generally, custom orders may take 4-10 weeks. We always work to meet our client’s timeline and provide accurate estimates during the initial consultation.

CAD Files in Any Format: Whether it’s 2D or 3D, we accept STP, IGES, X_T, DWG, PDF, STL, ensuring no design is too complex for us to handle.

Project Specifics: Share your expected quantities, desired machining processes, and material requirements to help us tailor our services perfectly to your needs.

Finishing Touches: Specify any secondary operations such as finishing details, heat treatments, anodizing, or plating to ensure your parts meet the highest standards.

Compliance and Certifications: Let us know about any critical industry standards or customer specifications you adhere to, including First Article Inspection, PPAP requirements, and necessary certifications.

Additional Insights: Any target pricing, desired lead times, or other pertinent information will help us align our services with your expectations.

As a company established in 2006, we deeply understand the importance of integrity, and protecting the privacy of our customers is something we take extremely seriously. We can sign a NDA(non-disclosure agreements) before receiving your drawings, so please feel free to leave your design to us!

That’s not a problem. Just send us the photos of each angle, tell us the overall dimesions, material, surface treatment and QTY of the sample, and we will quote an approximate price. If you think the price is right, we then make samples based on the drawings we get and adjust them to perfection.

Quality assurance is integral to our manufacturing process. We employ several quality control measures including:

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.