Chrome plating is one of the most prominent metal finishing techniques for industrial applications and OEM machining parts. Do you know why? Because chrome plating is excellent for highly corrosive equipment. Chrome reduces the possibility of rust and reinforces the underlying material's strength. Chrome also has a high lubricity, which helps to prolong the lifespan of OEM machining items by minimizing friction.

Moreover, Chrome plating is so strong and durable that it is not easy to remove. So, If you want to deposit any other coating then it will not be possible until the chrome plating is removed.

Thus, in this blog, we will talk about the types of chrome plating, how it is deposited, and ways to remove them in detail. So let’s dive deep into it.

How Chrome Plating is Deposited?

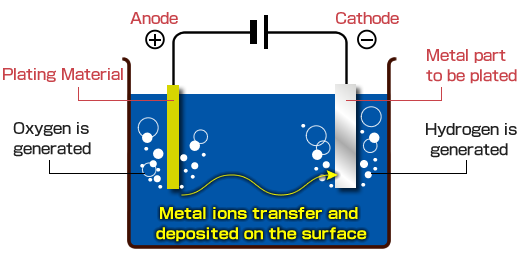

The chrome plating technique employs electroplating, which is a common method of coating one metal with another using electricity. In this scenario, chromium plating is used on the metals like aluminum and steel.

The chrome-plated item is first cleaned before being immersed in a chromic acid solution. Electricity is sent across the solution, causing the chromium ions to cling to the object's surface. By varying the time of deposition, the thickness of the chromium coating may be regulated.

How Much Chrome Plating is long-lasting?

The wear life of hard chrome plating changes according to the application and climate, but it normally enhances the lifespan of the core OEM machined products by 2 to 10 times. The longevity of any chrome plating is determined by various factors, including:

- Surface preparation technique and maintenance

- The quality of the Plating solution

- The plating layer's thickness

It's very important to carefully choose all the criteria for chrome plating. Always make sure to use clean and purify materials for plating. So, the final finish of the OEM machined product’s surface should be of high quality. It can withstand tough and non-wear environment circumstances.

Types of Chrome Plating

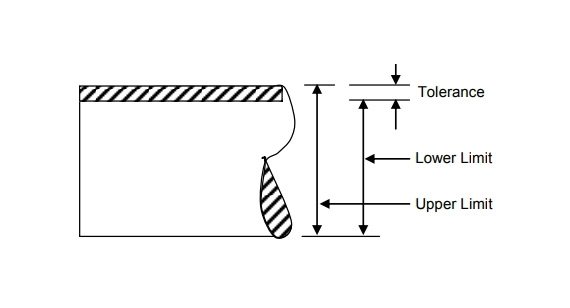

On the basis of deposition thickness, chrome plating can be classified into two types of chrome plating.

- Decorative chrome plating

- Hard chrome plating

Figure 1: hard chrome plating, Figure 2: thin/ decorative coating.

Decorative Chrome Plating

Bright plating is another term for this type of chrome plating. The normal thickness range for decorative chrome plating is thin in the range of 0.005mm to 0.015mm. This isn't to argue that the chrome plating would not shield the material from rust and wear; it simply isn't as effective as hard chrome plating at doing so.

One distinctive feature of decorative chrome plating is that it requires the material to have a bright nickel plate before the chrome plate is applied. This is intended to offer the material's glossy, smooth, and highly corrosive qualities.

Hard Chrome Plating

This is often referred to as industrial chrome. This type of plating is heavier than aesthetic plating and is used for substances that need to be more functional and robust. Because of its high ductility and durability, hard chromium coating is useful for decreasing friction.

Micro-cracked chromium, micro-porous chromium, porous chromium, and crack-free chromium are all examples of hard chrome. To provide acceptable corrosion resistance, the micro-cracked and porous coatings should have a minimum thickness of 80-120µm.

Apart from friction, its ductility and durability ensure that materials with this sort of coating are more enduring and resilient to wear and tear. Hard chrome's normal thickness ranges from 0.013 to 0.038mm.

Another outstanding property of hard chrome plating is its ability to increase chemical barrier properties, particularly oxidation resistance.

How Can Chrome Plating be Removed

If you want to apply some other coating then it's very necessary to remove the chrome plating before other deposition. So, it's very essential to know how can chrome plating be removed.

Specialized Tools

Specialized machinery and tools are used in the removal of chromium from diverse materials. One benefit of using these tools and machinery is that they can work with both plastics and metals.

This option is the most costly but also the most efficient choice. Find a reliable specialist with experience removing chrome plating if you want to proceed this way.

Ultrasonic Cleaner Procedure

An ultrasonic cleaner is another piece of specialized equipment that can be used to remove chrome plating. Ultrasonic cleaners, which are typically used to clean sensitive electronic items or jewelry, employ high-frequency sound waves to remove any dirt, grease, and other residues from objects.

The primary benefit of using an Ultrasonic cleaner is that it provides a safe and simple method of removing chrome from OEM machined parts.

But, the investment of purchasing one for a one-time chrome eradication effort may not be worth it. Furthermore, due to their small size, they can only be used to remove the chrome plating of small things.

Abrasive Blaster

An abrasive blaster is an instrument that aids in blasting operations. The abrasive or is also called sandblasting machine uses sandblasting, shot peening, and other procedures that use microparticle powder or small particles to erase chrome coating.

This method can be used to remove paint, rust, or other deposits, among other things.

When done appropriately, abrasive blasting is generally safe, however, there are some hazards involved with the procedure. These include dust particle inhalation, eye injury, and skin irritation from blasting material exposure.

Abrasive blasters are frequently seen at auto shops, where they are used to remove chrome or other finishes from automotive parts. The high-pressure discharge of abrasive particles removes the chromium covering, leaving the OEM machined part’s surface exposed and intact.

Therefore, it's very important to wear goggles and gloves while using this procedure. This is due to the possibility of the discharge of very fine particles and dust into the air, which can be poisonous and unpleasant when it comes into contact with the eyes and lungs.

Chemical solution method

In chemical procedures, different chemicals are used to wipe off the coating.

Hydrochloric Acid

Hydrochloric acid is a strong highly acidic element with similarly high corrosive characteristics. However, when stripping chrome plating from materials, this corrosive tendency comes in handy. Hydrochloric acid is often utilized in high levels, such as 30-40%.

In this procedure first, immerse the chrome-plated material in the acidic media and wait for the acid to do its work. The chromium coating will eventually wear away and must be removed from the acidic media. Leaving the OEM machined part in the strong hydrochloric acid solution for an extended period of time can cause harm.

After removing the chrome, carefully wash and rinse the material with detergent and water. Allow drying. But, this procedure can’t be used for plastics to eliminate this coating. This is because many chemicals have highly corrosive characteristics, particularly at high concentrations, on plastic materials.

Sodium Hydroxide

For bases, use sodium hydroxide. Because sodium hydroxide solution is extremely basic, it can be used to remove chrome plating from some metals.

The removal technique is similar to that of acid solutions in which the chrome plating is eliminated by being immersed in the solution and allowed to react. As a result, the chrome immersed in the solution is also stripped off. Following that, the material must be washed with detergent and water, washed, and allowed to dry.

Electroplating in reverse

This is another procedure to eliminate the chrome coating. This approach should only be undertaken by an individual who is familiar with electrical and chemicals. Toxic and harmful vapors will be released during the process, and there is a considerable risk of drowning due to continuous exposure.

Benefits

After discussing so many details about chrome plating now it is very important to know what are the basic benefits of using this coating. So, let’s explore this in detail.

- It can be used on a variety of products like metals, stainless steel, copper, brass, and others.

- It could be used at low temperatures.

- It's appropriate for complex OEM machine products and irregular geometries, such as holes and bores.

- It has good adhesion, there is little chance of delamination or peeling during use.

- It also has a brilliant and glossy finish, making it ideal for exposed parts.

What is the industrial application?

Chrome plating is often used for one of 2 reasons: decorative or industrial. Chrome plating is generally used where a very high degree of hardness on the surface of a metal is required to improve abrasion resistance, friction, anti-galling qualities, and in some circumstances corrosion resistance.

It is used widely in the industrial sector for automotive parts, shafts and rotors. It is also used in roll mold, dies, and hydraulic pistons.

Conclusion

Chrome plating is a popular metal finishing process for industrial applications. Due to its ductility and durability, OEM machined products with this type of coating are more durable and resistant to wear and strain. The usual thickness of hard chromium is 0.02 to 0.04mm.

In this blog, we discussed in detail how chrome plating is effective for industrial applications. We elaborated on the methods of deposition, types, and how this coating can be removed before any deposition.

One of the most important things is if you couldn't get any clear idea about chrome plating and how to remove it. You should consult with an experienced company like Baichuan. Our experts will guide you about your project.

If still you have any queries let us know by leaving your comment below.