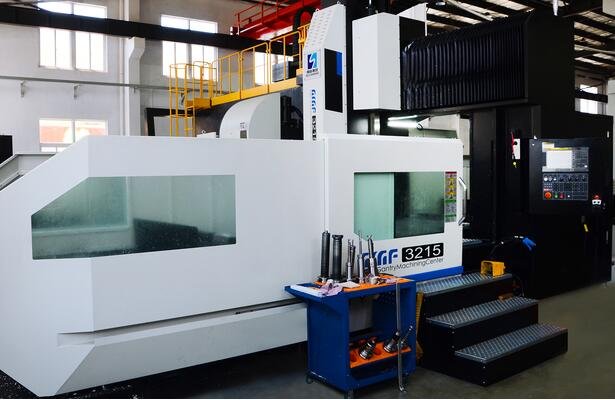

The gantry machining center is a high-speed CNC machine with integrated design of fixed beam and column of gantry frame. It has the characteristics of high rigidity and accuracy and stability. Beam, moving beam, sliding seat, pillow, spindle, tool magazine, hydraulic system, lubrication system, electrical system, accessory head magazine and other components, mold, aerospace, rail transit, automobile and other manufacturing industries.

The gantry machining center refers to a machining center in which the Z axis of the spindle is perpendicular to the worktable. The overall structure is a large machining center composed of double columns and top beams.

The content of the machining accuracy of the machining center:

1) Dimensional accuracy of parts

Refers to the consistency of the actual size of the part after processing with the machining center and the center of the tolerance zone of the part size.

2) Shape accuracy

Refers to the consistency between the actual geometry of the surface of the part processed by the machining center and the ideal geometry.

3) Position accuracy

It means that the actual position accuracy of the relevant surface of the part processed by the machining center is poor.

4) Mutual relations

The design of mechanical parts generally stipulates the machining accuracy of the parts. It should be noted that the shape error should be controlled within the position tolerance, and the position error should be less than the dimensional tolerance. Or it can be understood that precision parts or important surface shape accuracy requirements of parts are higher than positioning accuracy requirements, and positioning accuracy requirements are higher than dimensional accuracy requirements.

The gantry machining center is a machining center whose axis is perpendicular to the worktable. The overall structure is a large door frame machining center composed of double columns and top beams.

The machining center is a continuation of the CNC milling machine. The biggest difference is that it can install tools for different purposes in the tool magazine, and the tool can be clamped in a single clamping by the tool changer. The machining tool on the spindle can be automatically replaced by the automatic tool changer. Realize a variety of processing functions.

The finishing feed route is mostly carried out in sequence along the contour of the part. Therefore, the focus of determining the roughing feed route is to determine the roughing feed route.