In semiconductor manufacturing, vacuum control plays a crucial role in production. It is essential to create a clean and contaminant-free environment to produce high-quality semiconductors. The control of vacuum pressure helps maintain an optimal environment for chemical reactions, leading to precise deposition and etching processes.

Precise pressure levels, base pressure, and pump speed are key parameters for achieving ideal conditions during processing.

Aside from controlling contamination levels, maintaining the specified temperature and pressure can also determine the success or failure of a project. Appropriate control over these factors improves device performance and increases production efficiency.

In this article, I will go into detail about how to vacuum control improves semiconductor production, explaining how it helps increase process efficiency and yield and how it helps push the semiconductor industry forward as a whole.

Without vacuum control, semiconductor manufacturing would be like trying to bake a cake in an erupting volcano.

Semiconductor Manufacturing

Semiconductor manufacturing is the process of creating semiconductor devices, which are widely used in electronics. It has several stages, like designing, testing, and fabrication. Vacuum is used during fabrication, to make sure the semiconductors are clean and defect-free.

Vacuum control is really important here. It reduces contamination from particles and other substances, which could affect the quality of the end product. A low-pressure environment gives higher precision when etching, depositing, and cleaning wafers. Vacuum control is becoming increasingly critical for semiconductor manufacturers. It helps to improve yield and lowers production costs.

For your better understanding, here’s a video that describes semiconductor manufacturing:

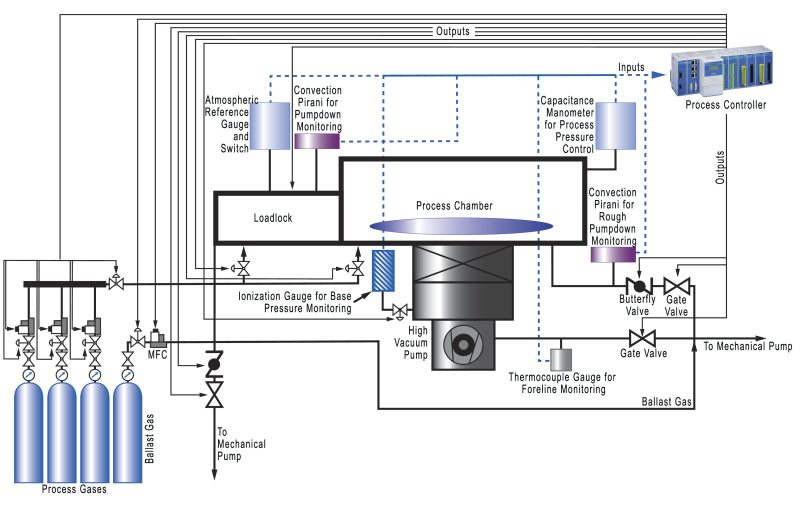

Types of Vacuum Control Systems

In this section, we will explore three sub-sections: “Physical Constraints of Systems,” “Variable-Speed Pumps,” and “Active Gauge Control.” Each of these sub-sections offers unique solutions to the challenges of maintaining a controlled vacuum environment.

Physical Constraints of Systems

Physical boundaries and restrictions govern the limitations of vacuum control systems. The performance of these systems is affected by factors including system configuration, operating conditions, and materials compatibility. These physical constraints affect the ultimate limit of vacuum attainable and the stability of vacuum levels achievable.

Different types of vacuum control systems have unique physical constraints that need to be considered for optimal performance. For example, thermal constraints in cryogenic or high-temperature environments can limit the range for system operation. In contrast, mechanical limitations with mechanical pumps dictate the maximum pressure differences achievable.

The effectiveness of vacuum control directly correlates to the underlying assumptions made concerning process requirements. Different applications require specific ranges of pressures and flow rates, which place additional physical demands on a system dependent on the application context.

Source:

https://northerncal.swagelok.com/blog/semiconductor-vacuum-systems-snc

A notorious example of physical constraints affecting the field was during NASA’s preparations for the Apollo missions when they had to perfect their use of vacuums as there was no atmospheric pressure in space. This required significant technological advancements leading to several breakthroughs in designing effective vacuum control systems capable of operating under these unique circumstances.

Variable-Speed Pumps

Here’s the information presented in the table:

| Features | Benefits |

| Automated Control | Allows for accurate and consistent pump speed regulation. |

| Vacuum Flow Adjustment | Pump speed can be adjusted to accommodate changes in demand and process requirements. |

| Efficiency | Reduces energy consumption by only operating at necessary speeds, therefore minimizing power usage and operational costs. |

In addition to the table information, it’s worth noting that Variable-Speed Pumps can provide better system performance by sustaining pressure levels within a narrow range while reducing stress on system components.

As far as history goes, these pumps were initially used in industrial settings to reduce power usage and minimize costs. Rapid technological advancements have improved their capabilities, making them ideal for various applications such as pharmaceuticals, food processing, and chemical manufacturing.

Active Gauge Control

Utilizing an advanced control system, the measurement and regulation of a vacuum gauge can be achieved. Examples of active gauge control systems include Thermostatic Control, Piezoelectric Control, and Pressure Transducer Control.

It is essential to note that these controls have unique capabilities that allow customization based on specific user requirements. Furthermore, they can improve accuracy and stability and reduce false readings or errors.

Pro Tip: Employing various active gauge control systems provides a more efficient and reliable vacuum operation. Choosing the right vacuum control system is like finding a needle in a haystack, except the needle is critical in maintaining a stable vacuum environment.

Importance of Vacuum Control in Semiconductor Manufacturing

To achieve optimal results in semiconductor manufacturing, vacuum control is key. In this section, we’ll discuss the importance of controlling vacuum levels with respect to key challenges. You’ll explore the ways of minimizing contaminants to improve yield, how controlled vacuum levels enhance performance, and the cost-efficient ways of achieving these outcomes.

Reduction of Contaminants

The control of vacuum plays a critical role in semiconductor manufacturing as it reduces the presence of impurities or contaminants in the process. These impurities can degrade product quality and performance, leading to high failure rates and economic losses.

By reducing contaminants, vacuum control ensures consistent product quality, enabling manufacturers to produce high-performance semiconductors with improved functionality. Additionally, it helps to optimize production yields while reducing the risk of defects caused by chemical reactions between contaminant particles and the semiconductor surface.

It is worth noting that sophisticated equipment is utilized for vacuum control in semiconductor manufacturing. For instance, ion pumps, cryogenic pumps, and turbomolecular pumps are used to maintain ultra-high vacuum conditions during various stages of the manufacturing process. Moreover, leak detectors are employed to detect any leaks in vacuum systems that could potentially cause contamination.

Pro Tip: It’s crucial to regularly monitor and maintain a vacuum system’s status by conducting frequent leak detection tests to prevent any unexpected issues that could arise during production runs.

Improved Yield

Vacuum Control and Increased Manufacturing Efficiency

Improved yield is one of the most significant advantages of efficient vacuum control in semiconductor manufacturing. This ensures that the production line meets the strict quality and performance standards demanded by this industry.

- Vacuum control plays a vital role in precision cleaning and other critical processes such as chemical vapor deposition (CVD), etching, and sputtering, leading to improved uniformity of thin films.

- Improvements in vacuum technology have led to better consistency in the size, shape, and crystal structure of semiconductor devices.

- The accurate measurement of vacuum levels, combined with precisely controlled flow rates during processing, has improved yields significantly while reducing operating costs.

- Investing in specialized equipment for vacuum control allows manufacturers to excel beyond their competitors in terms of improved yield.

Innovation in Vacuum Control Technology Leads to Greater Precision

The advancement of vacuum technology has brought about significant changes when it comes to semiconductor manufacturing efficiency. The innovation has resulted in improved vacuum pumping speed as well as lower power consumption.

Fact: A Semiconductor Industry Association (SIA) study showed an increase from 191 billion dollars in sales from 2013-2016 to 412 billion dollars from 2017-2020 due to technological advancements.

Enhanced Performance

Vacuum optimization in semiconductor production leads to enhanced device output and performance. Achieving ideal vacuum levels with proper electronic monitoring tools can reduce contaminants, achieve uniform processing, and minimize defects. The intended level of vacuum influences the overall yield rate of the devices; hence, its control cannot be understated.

Source:

Maintaining stable and optimal equipment performance requires accurate measurement of process parameters to create a suitable environment for semiconductor manufacturing. This, in turn, ensures consistent manufacturing quality across multiple rounds without significant deviations from target specifications. In addition, controlled atmospheric pressure can facilitate the simultaneous processing of multiple substrates, thereby reducing the cost per item.

Reducing particle contamination through efficient vacuum control results in superior product quality and reduced cost per chip by limiting wafer reworks or discards if defects go unobserved. Efficient control allows automated testing processes to assess precisely before ever damaging a silicon wafer.

As per industry sources such as “Cleanroom Technology International,” it is believed that preventing workplace contamination within Chambers maintains cleanliness levels during pre-cleaning and improves the already existing handling protocols, thereby increasing efficacy and compliance levels throughout all manufacturer safety standards are adhered to when using vacuums in a cleanroom environment.

When it comes to semiconductor manufacturing, vacuum control is the ultimate performance enhancer – move over steroids.

Cost Efficiency

The optimization of equipment and processes in semiconductor manufacturing is necessary for maximized efficiency. Tight control over vacuum technology significantly contributes to achieving this efficiency. It improves production yields, reduces system downtime, and consequently cuts costs, making the entire operation more economical.

To enhance cost efficiency, each element of a semiconductor manufacturing process needs to operate at an optimal level. Vacuum control ensures the maintenance of the necessary cleanroom environment for microchip fabrication while minimizing contamination risk from outside sources.

Moreover, a closed-loop automated vacuum system significantly decreases operator error or uncertainty due to human interaction with the process. Reliable vacuum systems can increase production uptime significantly, eradicating downtime losses and maximizing profitability.

Semiconductor manufacturers historically use both diffusion pumps and turbo-molecular pumps. However, modern technology has seen an uptick in the adoption of dry pump designs that offer high pumping speeds and low cost of ownership.

If saving money was an Olympic sport, vacuum control in semiconductor manufacturing would be the gold medalist.

Factors to Consider in Vacuum Control Systems

To optimize your vacuum control system for semiconductor manufacturing, it is essential to consider various factors. In order to ensure peak performance and maximum yield, you must pay attention to operational requirements, maintenance requirements, and environmental constraints. These three sub-sections will offer insight into how each factor impacts the vacuum control system.

Operational Requirements (h3)

To effectively operate a vacuum control system, there are several requirements to consider. These include the necessary components, pressure range, and automation capabilities.

In the table below, we present a breakdown of the different operational considerations for vacuum control systems.

| Operational Considerations | Components Required | Pressure Range (mbar) | Automation Capabilities |

| Vacuum Pump | Yes | 10^-3 – 10^5 | Yes |

| Pressure Sensor | Yes | 10^-12 – 10^5 | Yes |

| Flow Control Valve | Optional | N/A | Yes |

Aside from these key elements, it is important to note that different applications may require additional components or features. For example, some systems may need specialized materials for compatibility with specific gases or liquids.

It is crucial to ensure that all necessary specifications are met in order to achieve optimal system performance and avoid equipment failure. Don’t miss out on the benefits of an effective vacuum control system – carefully evaluate your operational requirements before making any purchasing decisions.

Maintenance Requirements

One essential aspect of vacuum control systems is the upkeep of the equipment, which can be referred to as maintenance needs. These requirements include regularly checking the suction levels, cleaning filters, and ensuring that there is no blockage in the pipes or hoses. Failing to take care of these responsibilities could result in inefficient system performance or even failure.

To avoid costly downtime, it’s essential to train personnel responsible for maintaining the vacuum control system adequately. One way to do this is by providing them with proper documentation outlining necessary inspection procedures and how to troubleshoot problems promptly. Additionally, having a reliable maintenance schedule that adheres to the manufacturer’s recommendations can prevent critical issues from arising.

It’s also crucial to choose high-quality components when designing or upgrading a vacuum control system. Some components may require more attention than others, such as pumps that may wear out over time and need replacement. By investing in durable equipment upfront, you can minimize maintenance costs over the life of your system.

Overall, maintaining a well-functioning vacuum control system requires regular inspection and proper training for personnel responsible for upkeep. Investing in quality components can also cut down on future repair expenses and ensure reliable performance for years to come.

Trying to control a vacuum in a dusty environment is like trying to keep a clean house with a group of toddlers running around.

Environmental Constraints

In vacuum control systems, the natural environment plays a significant role. Environmental factors such as temperature, humidity, and air quality should be precisely measured and controlled. These factors affect different elements of the system, like noise level, and performance intimation, and trigger unexpected faults.

One environmental constraint to consider is the temperature. The temperature must be maintained at appropriate levels since changes in temperature lead to changes in pressure, affecting the efficiency of the vacuum pump or compressor. Therefore, an environmental monitoring system that measures temperature continuously is crucial to regulate the temperature.

Another factor that can hinder vacuum control includes humidity levels in the environment. High levels of moisture can significantly reduce the performance and lifespan of some vacuum pumps with increased rusting rates. Additionally, condensation can occur in some electronic components leading to short circuits hence destroying other parts of the system.

Source:https://www.mks.com/n/semiconductor-vacuum-pressure-control

A little-known fact about environmental constraints is that dirt particles found within the environment may damage particular components within a vacuum control system when they circulate through it during operations. For this reason, filters should be used to block dust/ particles from entering electronic components and contaminating oil reservoirs or gas pipes.

Frequently Asked Questions (FAQs)

What types of vacuum control are used in semiconductor manufacturing?

The two main types of vacuum control used in semiconductor manufacturing are pressure control and flow control. The pressure inside the chamber is controlled using a number of sensors and valves, whereas the flow of gases into and out of the chamber is controlled using flow control.

Why vacuum is used in the semiconductor industry?

A higher quality treatment is possible when activities like film formation and etching are carried out in a vacuum with few contaminants. It is possible to treat wafers at low temperatures by reducing the boiling point.

Can vacuum control be used in all stages of semiconductor manufacturing?

Vacuum control can be used in most stages of semiconductor manufacturing, including deposition, etching, and cleaning. However, the specific type and level of vacuum control required may vary depending on the stage and process being used.

What factors affect the effectiveness of vacuum control in semiconductor manufacturing?

The effectiveness of vacuum control in semiconductor manufacturing can be affected by several factors, including:

- The purity of the gas used

- The design and condition of the vacuum system

- The level of vacuum maintained

- The type of process used to produce the semiconductor material

In what specific semiconductor manufacturing processes does vacuum control play a role?

Several critical processes in semiconductor manufacturing require vacuum control. Examples include chemical vapor deposition (CVD), physical vapor deposition (PVD), ion implantation, etching, and cleaning processes. These processes often take place in vacuum chambers or systems to ensure precise and controlled conditions.

Final Thoughts

The importance of vacuum control in the manufacture of semiconductors cannot be overstated. Cleanliness is essential for high-quality semiconductor products. Vacuum control helps achieve and maintain this cleanliness by stabilizing pressure, filtering out contaminants, and removing moisture.

It also ensures consistency in production, allowing precise control and monitoring equipment to reduce the rate of defects. For professional manufacturing, advanced technology is needed to manage environmental factors and achieve top-notch results. In addition to the advantages provided by vacuum control, it also allows manufacturers to adhere to industry standards.