What is the margin?

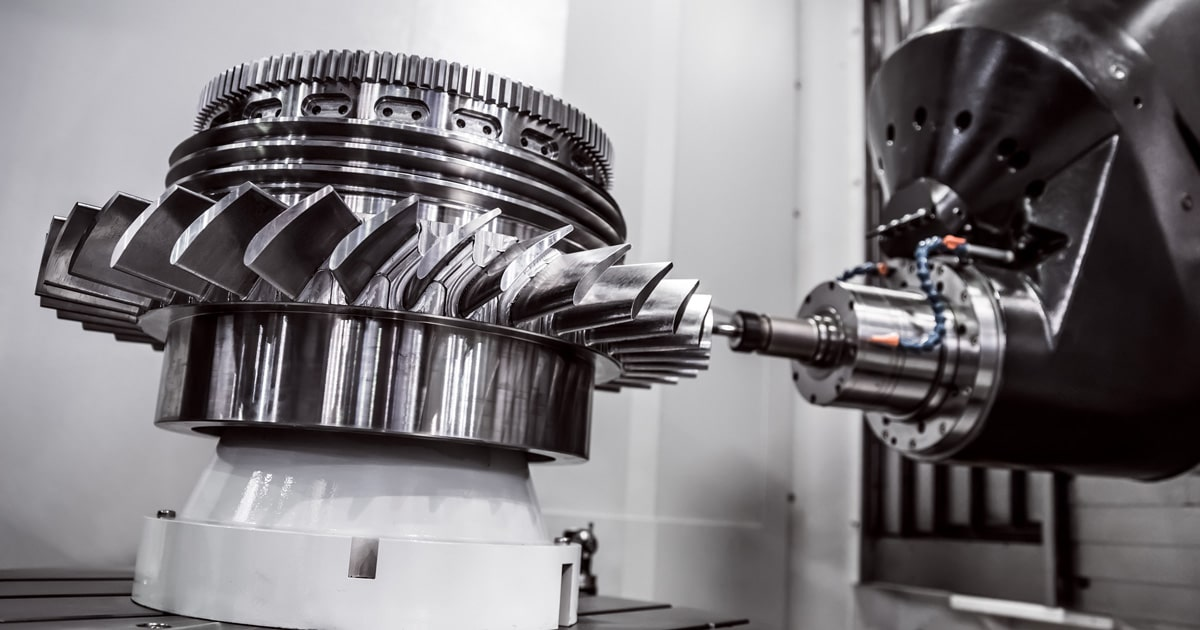

In precision CNC machining, in order to process qualified parts, a part of the metal must be cut from the blank, and the thickness of that layer of metal is called the machining allowance. Machining allowance can be divided into process allowance and total allowance. The thickness of the layer of metal that needs to be removed in a process is called the machining allowance of the process. The total allowance that needs to be removed from the blank to the finished product is called the total allowance, which is equal to the sum of the allowances of each process on the corresponding surface.

Purpose of margin

The purpose of leaving a machining allowance on the workpiece is to remove the precision CNC machining errors and surface defects left by the previous process, such as the chill layer, pores, sand inclusion layer on the surface of the casting, oxide skin on the surface of the forging, decarburization layer, Surface cracks, internal stress layer after machining and surface roughness of CNC machining, etc. Thereby improving the accuracy and surface roughness of the workpiece.

The meaning of margin

The size of the machining allowance has a great influence on the machining quality and production efficiency. Excessive machining allowance not only increases the labor of machining and reduces productivity, but also increases the consumption of materials, tools and electricity, and increases the cost of precision CNC machining. If the machining allowance is too small, it can neither eliminate various defects and errors in the previous process, nor compensate for the clamping error during processing in this process, resulting in waste products. The selection principle is to make the margin as small as possible on the premise of ensuring the quality. Generally speaking, the more finishing, the smaller the process allowance.

Precision parts processing requires the production of high-quality and stable products, so how to improve the quality of precision parts processing in the production of CNC precision machining?

First of all, the staff must have rich working experience in machining and excellent technology. Machining must have excellent technology to do well. It is well known that machining is the same fine work. It is a very test of the production process. Even if it can be done well, it will take a long time. If you don’t start well at the beginning, it is easy to give up.

Secondly, whether the processing process is standardized and excellent also determines whether the product is of high quality. It is also an indispensable reference point that we use to formulate company rules and regulations. Both production and management necessarily require a set of perfect processes, which serve to make perfect products.