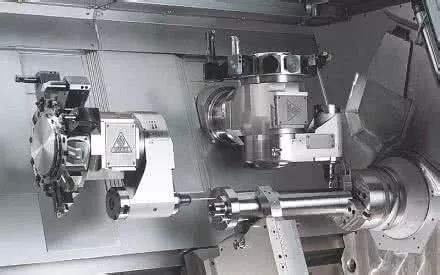

CNC machining center is a centralized and multi-process integrated production equipment. It can clamp production and processing at one time for multi-process production and processing, and can process steel parts with complex products, complex technological processes and high precision requirements. The CNC machining center can update the multi-axis CNC machining center, expand the scope of production and processing, and produce and process multi-faceted products. Therefore, the production and processing range of CNC machining centers is very common. Let's discuss what kind of parts and their molds can be produced and machined by a CNC machining center.

Available production and processing areas of CNC machining centers:

CNC machining centers can be used in major manufacturing industries. The CNC machining center can be used for the production and processing of steel parts with complex shapes such as shell steel parts, complex inclined steel parts, special-shaped steel parts, disc steel parts, shaft steel parts, and plate steel parts.

CNC machining center to produce and process shell steel parts:

CNC machining center CNC machining center shell steel parts generally require high-precision hole system and its plan for production and processing. When the CNC machining center produces and processes shell steel parts, one clamping can carry out 60%~95% of the production and processing technology.

CNC machining center for producing and machining beveled steel parts:

Generally speaking, the production and processing of complex sloped steel parts are CNC machining centers with four-axis linkage. For example, five-axis machining centers can produce and machine a variety of complex beveled steel parts. The three-axis CNC machining center can also use simple inclined steel parts, but the three-coordinate production and processing of the ball head turning tool is essential. In the production process, the efficiency is relatively low. Three-axis CNC machining centers are used for complex inclined steel parts, and the machine cannot be processed because the three-axis CNC machining center only produces and processes simple inclined steel parts, and complex inclined steel parts cannot be produced and processed, such as centrifugal impellers, blades, marine propellers, etc. Complex beveled parts must be produced and machined by a five-axis CNC machining center.

CNC machining center produces and processes special-shaped steel parts:

What are special-shaped steel parts? Special-shaped parts refer to parts that are mixed with points, lines and surfaces. Its exterior design is very strange and irregular. The production and processing of such steel parts must be applied to five-axis CNC machining centers. The more complex the production and processing of special-shaped parts and the higher the precision requirements, the greater the advantages of CNC machining centers. such as supports.

Production and processing of discs, sets, and sheet steel parts Production and processing of discs, sets, and sheet steel parts.

There are many such steel parts, including porous structural systems, swash plate sleeves or mechanical parts such as shaft sleeves with flanges, shaft parts with healthy grooves or square heads, etc. , as well as sheet metal parts produced and processed with porous structures, such as various motor covers.