Heat treatment and CNC machining are two processes that shape not just the geometry of a part, but its behavior after machining. Heat treatment alters the internal structure of a material to improve strength, hardness, or toughness. CNC machining removes material to achieve precise dimensions and surface finishes. When these processes are combined, the order in which they are performed can strongly influence accuracy and repeatability.

Heat Treatments in CNC Machining

The sequence matters because both machining and heat treatment introduce and release internal stresses. If these stresses are not managed correctly, parts can bend, twist, or drift out of tolerance during machining or after final processing. Distortion, residual stress, and long-term dimensional stability are common challenges, especially in precision components.

Understanding Residual Stress and Distortion in Machined Parts

Before deciding when to apply heat treatment, it is important to understand why machined parts distort in the first place. Most dimensional issues do not come from poor programming or machine accuracy. They come from internal stresses that were already present in the material or were introduced during processing. These stresses remain hidden until material is removed or the part is exposed to heat.

What residual stress is and how it forms

Residual stress is internal stress locked inside a material even when no external force is applied. It forms during several stages of material production and processing. Rolling, forging, casting, welding, machining, and heat treatment can all leave stress behind. In machining, residual stress develops when cutting forces and heat cause localized plastic deformation. The surface layer may be compressed while the core remains in tension, or the reverse, depending on the process.

Heat treatment can also create residual stress when parts are heated and cooled unevenly. For example, during quenching, the outer layers cool and contract faster than the core. This difference in cooling rate creates internal stress even if the part looks straight when removed from the furnace.

Common sources of distortion in CNC parts

Distortion usually appears when residual stress is allowed to redistribute. The most common triggers include:

- Removing large amounts of material from one side of a part

- Uneven clamping or over-tight fixturing

- High cutting temperatures during roughing

- Non-uniform cooling during heat treatment

A common shop example is a flat plate that stays straight during rough machining but warps after being unclamped. The act of removing material releases stress that was previously balanced within the stock.

How internal stress redistributes during machining

When material is removed, the internal stress balance changes. Areas that were held in equilibrium suddenly become free to move. This is why distortion often appears after a machining pass rather than during it. A long bar may bow after a slot is machined along one side. A thin plate may twist once the pockets are opened.

This effect is more pronounced during rough machining because larger volumes of material are removed quickly. If no stress-relief step is included, the part continues to move during later operations, making it difficult to hold tight tolerances.

Why certain geometries are more vulnerable

Not all parts respond to stress the same way. Thin-walled components, long parts, and asymmetric designs are especially sensitive. These geometries lack the stiffness needed to resist stress redistribution. For example, aerospace brackets with deep pockets often distort after rough machining unless intermediate stress relief is applied.

Parts with uneven wall thickness also tend to move more because stress is released unevenly. Even small differences in geometry can lead to measurable flatness or straightness errors.

Typical signs of stress-related distortion

Stress-related distortion often shows up in predictable ways. Machinists may notice that a part measures correctly while clamped, but goes out of tolerance after removal. Flat surfaces may show gradual bowing rather than sharp bends. Hole positions may shift slightly after finishing operations.

These signs indicate that residual stress was not properly managed earlier in the process. Understanding these behaviors is the foundation for deciding whether heat treatment should be applied before or after CNC machining.

Heat Treatment Before CNC Machining (Pre-Machining Heat Treatment)

Applying heat treatment before CNC machining is often used to stabilize raw material before significant cutting begins. In this approach, the material is heat-treated in its near-raw form, such as a billet, forging, or plate, before any critical dimensions are machined. The goal is not final hardness, but stress reduction and structural uniformity.

How pre-machining heat treatment works in practice

Pre-machining heat treatment typically involves annealing, normalizing, or stress relieving. These processes reduce internal stress created during rolling or forging and produce a more consistent microstructure. In many shops, large steel blocks are stress relieved before rough machining to prevent movement during heavy material removal.

For example, a thick alloy steel plate used for a machine base may be normalized before machining. This helps ensure that when pockets and mounting surfaces are machined, the plate remains flat instead of pulling into a shallow curve.

Key benefits of heat treatment before machining

One of the main advantages is improved stability during early machining stages. With internal stresses already reduced, the material responds more predictably to cutting forces. This leads to fewer surprises during roughing and semi-finishing.

Additional benefits include:

- Reduced the risk of sudden part movement during rough machining

- More consistent chip formation and cutting behavior

- Improved repeatability when machining large or heavy sections

Machinists often notice that tools cut more smoothly and dimensions remain closer to nominal throughout the process.

Limitations and trade-offs

Pre-machining heat treatment is not without drawbacks. Depending on the process, the material may become harder or tougher to cut. This can increase tool wear and machining time. In some cases, the final machining steps reintroduce stress, especially if aggressive finishing passes are used.

Another limitation is that pre-machining heat treatment does not guarantee final dimensional stability. Once the part is fully machined, additional stress relief may still be required before final inspection.

Best use cases for pre-machining heat treatment

This approach is most effective when large volumes of material must be removed or when working with stock that has a history of movement.

Typical applications include:

- Large billets and forged components

- Parts with heavy roughing operations

- Early stages of multi-step machining workflows

In these cases, stabilizing the material upfront reduces the risk of distortion later and simplifies downstream machining operations.

Heat Treatment After CNC Machining (Post-Machining Heat Treatment)

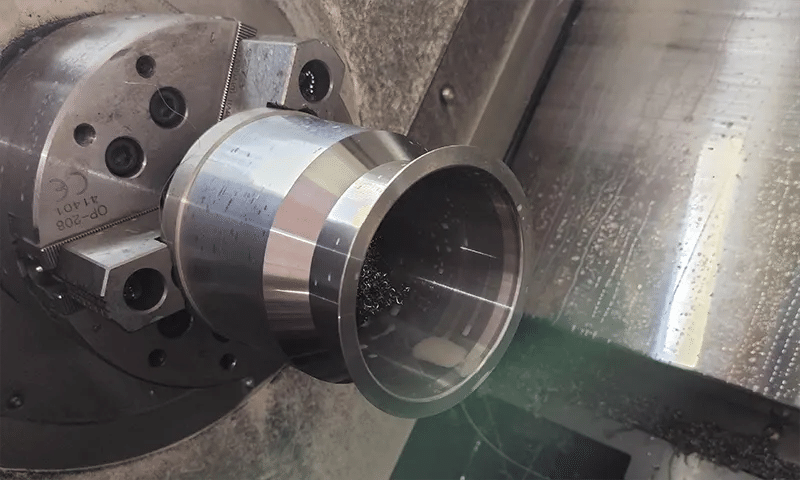

In many precision applications, heat treatment is performed after CNC machining to achieve the final mechanical properties required for service. In this sequence, the part is machined close to its final shape before being heat-treated. The focus shifts from material stability during cutting to performance in the finished component.

Heat Treatment After CNC Machining Of Precision Parts

How post-machining heat treatment is applied

Post-machining heat treatment is commonly used for hardening, tempering, or aging. The part is first machined in a softer or more machinable condition, then heat-treated to reach the target strength, hardness, or wear resistance. This approach is common in tooling, automotive components, and aerospace hardware.

For example, a precision steel shaft may be rough and finish machined in an annealed state, then quenched and tempered to achieve the required hardness. Aluminum aerospace parts are often solution heat-treated and artificially aged after machining to reach their final strength.

Benefits of heat treating after machining

The primary advantage is control over final mechanical properties. By heat treating at the end of the process, manufacturers ensure that the finished part meets performance requirements without compromising machinability earlier.

Key benefits include:

- Improved strength, hardness, and fatigue resistance

- Better wear performance in service

- Reduced cutting forces during machining due to the softer initial material

This sequence is especially useful when a tight surface finish or fine feature detail is required before the material becomes harder.

Risks related to distortion and accuracy loss

The main challenge with post-machining heat treatment is distortion. Heating and cooling can release machining-induced stress and introduce new thermal stress. Even parts that measured within tolerance before heat treatment may shift afterward.

A common example is a thin steel plate that remains flat after machining but develops measurable bowing after quenching. Hole positions may also move slightly, which can be critical in assemblies requiring precise alignment.

Common methods to reduce post-heat treatment distortion

To manage these risks, manufacturers often introduce control steps before and during heat treatment. Stress-relief cycles are frequently applied after rough machining and before final finishing. Machining allowances are left on critical surfaces so that final dimensions can be restored after heat treatment.

Additional measures may include controlled fixturing during heat treatment, especially for long or thin parts, and careful selection of heating and cooling rates.

Best use cases for post-machining heat treatment

Post-machining heat treatment is best suited for parts where performance outweighs the risk of dimensional change.

Typical applications include:

- High-precision components with defined strength requirements

- Parts with tight wear or fatigue specifications

- Components used in demanding thermal or mechanical environments

In these cases, dimensional corrections after heat treatment are planned into the workflow rather than treated as unexpected rework.

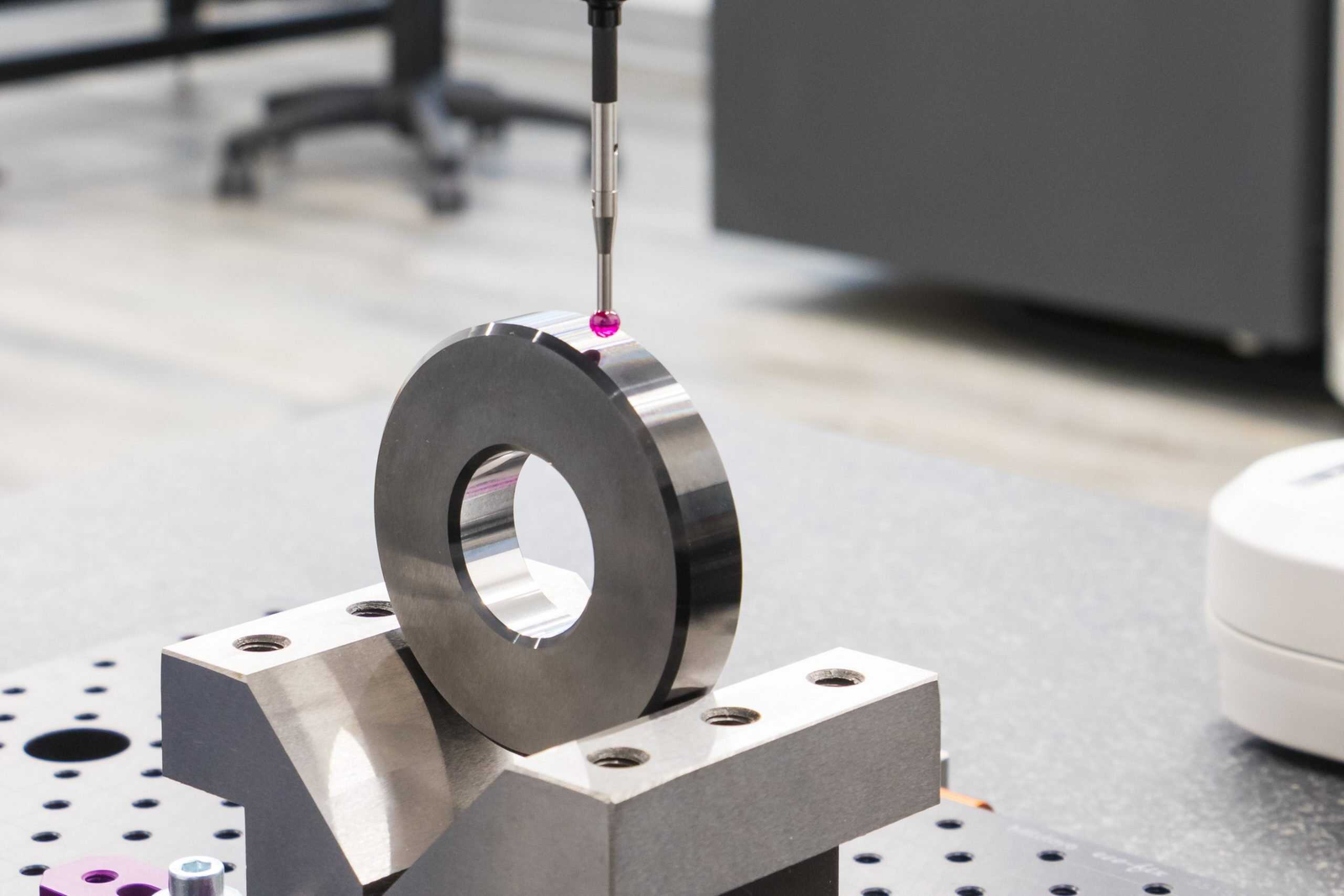

Dimensional Stability: Pre vs Post Heat Treatment Comparison

Once both approaches are understood individually, the real decision comes down to dimensional stability. Pre- and post-machining heat treatment affect how well a part holds its shape during machining, after processing, and over its service life. The differences are not theoretical. They show up clearly in tolerance control, flatness, and long-term performance.

Dimensional Stability in Aluminum Machining

Side-by-side impact on dimensional accuracy

When heat treatment is performed before machining, most internal stress from raw material production is already reduced. As a result, rough machining tends to be more stable. However, finishing operations can still introduce stress, especially if cutting forces are high or material removal is uneven.

With post-machining heat treatment, machining itself is usually easier and more predictable. The risk shifts to after heat treatment, where even small parts can move enough to exceed tight tolerances. This is why many shops plan a light finishing pass after heat treatment.

In practice, a machined steel block that holds ±0.02 mm before heat treatment may shift outside tolerance after quenching unless finishing stock was intentionally left.

Effects on flatness and straightness

Flatness and straightness are often the first characteristics affected by poor sequencing. Pre-heat-treated material tends to stay flatter during machining, especially for plates and bases. Post-heat-treated parts may lose flatness due to uneven thermal contraction, particularly in thin or wide components.

For example, long aluminum tooling plates often remain straight when machined from stress-relieved stock, but distort after solution heat treatment if not properly supported.

Long-term dimensional stability in service

Dimensional stability does not end at inspection. Parts exposed to load, vibration, or temperature changes can continue to move if residual stress remains. Pre-machining heat treatment generally improves long-term stability, especially for structural components.

Post-machining heat treatment improves mechanical strength, but if stress is not properly relieved beforehand, parts may slowly change shape in service. This is a common concern in precision fixtures and molds.

Influence of material type on sequencing decisions

Material selection plays a major role in choosing the right sequence.

- Carbon steel often benefits from stress relief before rough machining and hardening after final shaping.

- Alloy steel may require multiple heat treatment steps due to higher hardenability and distortion risk.

- Aluminum is sensitive to both machining stress and thermal cycles, making intermediate stress relief important.

- Titanium tends to distort during machining due to low thermal conductivity and benefits from conservative cutting and staged stress relief.

Each material responds differently, and the same workflow rarely applies across all alloys.

Role of intermediate stress-relief steps

Intermediate stress relief bridges the gap between pre- and post-machining heat treatment. By relieving stress after rough machining, manufacturers reduce movement during finishing and after final heat treatment.

This approach is common in aerospace and tooling applications, where parts are roughed, stress relieved, semi-finished, then heat-treated and finished. The extra step adds cost, but it often saves time by preventing scrap and rework.

Understanding these trade-offs makes it easier to select a sequence that supports both dimensional control and performance rather than sacrificing one for the other.

Best Workflow Practices to Minimize Distortion

Choosing the right sequence is only part of the solution. Distortion is best controlled through a complete workflow that considers machining stages, heat treatment timing, and part handling. Shops that consistently hold tight tolerances usually rely on proven sequencing strategies rather than a single heat treatment step.

Recommended sequencing strategies

One of the most effective approaches is rough machining followed by stress relief and then final machining. This allows most machining-induced stress to be removed before critical dimensions are produced. It is widely used for mold bases, machine frames, and aerospace structures.

Another common strategy combines pre-machining heat treatment with a light post-machining stress relief. In this case, the material is stabilized early, while the final stress introduced during finishing is reduced without significantly changing mechanical properties.

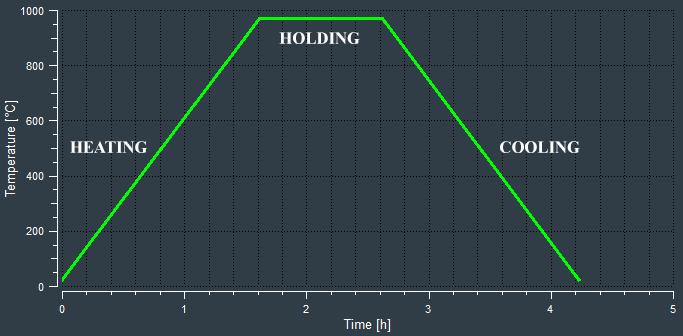

When to add stress-relief cycles

Stress-relief cycles are most valuable after heavy roughing operations or when large internal cavities are created. If a part shows movement after unclamping or requires repeated rework to meet flatness requirements, a stress-relief step is often justified.

Temperature-time scheme of simulated stress relief heat treatment process

For example, large steel fixtures are frequently stress relieved after rough machining. This prevents slow distortion that could otherwise appear weeks after delivery.

Machining allowances and finishing strategy

Leaving sufficient machining allowance is critical when post-machining heat treatment is planned. Finishing stock allows distorted surfaces to be corrected without scrap. The allowance should be large enough to clean up the heat treatment movement but small enough to avoid unnecessary cutting.

In high-precision work, finish machining is often limited to light passes with balanced material removal to avoid reintroducing stress.

Fixturing and clamping considerations

Poor fixturing can create distortion even in well-planned workflows. Over-clamping introduces artificial stress that is released when the part is removed. Fixtures should support the part evenly and reflect how it will sit in service whenever possible.

Thin or flexible parts benefit from modular fixtures that allow repositioning between operations, reducing the buildup of localized stress.

Decision checklist for selecting the right workflow

Before finalizing the process, manufacturers typically evaluate:

- Part geometry and stiffness

- Tolerance and flatness requirements

- Material type and heat treatment response

- Production volume and cost constraints

A high-volume automotive part may justify a simpler process, while a low-volume aerospace component often requires multiple stabilization steps.

By aligning heat treatment, machining strategy, and fixturing, manufacturers can significantly reduce distortion without excessive trial and error.

Cost, Risk, and Production Trade-Offs in Heat Treatment Sequencing

Beyond technical performance, the choice between pre- and post-machining heat treatment has clear cost and production implications. A sequence that delivers excellent dimensional stability may still be impractical if it increases cycle time or scrap risk beyond acceptable limits. This is where many manufacturing decisions are ultimately made.

Heat treatment for Precision Machined Parts

Cost impact of additional heat treatment steps

Each heat treatment cycle adds direct cost through furnace time, handling, and inspection. Indirect costs also increase due to longer lead times and work-in-progress inventory. Pre-machining heat treatment adds cost early but can reduce rework later. Post-machining heat treatment may seem cheaper upfront, but it can become expensive if parts distort and require secondary finishing.

For example, a shop producing low-volume tooling components may accept the added cost of intermediate stress relief to avoid scrapping expensive machined parts.

Risk of scrap and rework

Distortion-related scrap is one of the most expensive failure modes in CNC machining. Parts that move after final heat treatment often require re-machining, straightening, or complete rejection. This risk increases with tighter tolerances and more complex geometry.

In contrast, pre-machining heat treatment reduces uncertainty during cutting, which can improve first-pass yield. However, it does not eliminate the need for careful process control later in the workflow.

Production volume considerations

Production volume strongly influences sequencing decisions. High-volume parts benefit from simplified and repeatable workflows. If distortion is predictable and within manageable limits, post-machining heat treatment followed by minimal finishing may be sufficient.

Low-volume or one-off parts require a more conservative approach. In these cases, hybrid workflows with staged stress relief provide greater control, even if they add time and cost.

Balancing performance requirements with practicality

The most effective workflows balance dimensional stability, mechanical performance, and production efficiency. Parts that carry load, experience fatigue, or operate in high-temperature environments often justify additional heat treatment steps. Less critical components may tolerate minor distortion if it does not affect function.

Experienced manufacturers rely on historical data, past failures, and material behavior rather than theory alone. Over time, this practical knowledge becomes more valuable than any single rule about when heat treatment should occur.

By evaluating cost, risk, and production context alongside technical requirements, manufacturers can select a sequencing strategy that supports both quality and profitability rather than optimizing one at the expense of the other.

Conclusion

The sequence of heat treatment and CNC machining has a direct impact on residual stress, distortion, and dimensional accuracy. Pre-machining heat treatment improves stability during heavy material removal, while post-machining heat treatment ensures final mechanical performance. Each approach introduces different risks, and distortion often appears when stress is released rather than when it is created.

There is no single sequence that works for every part. The best results come from balancing dimensional stability, performance requirements, and production cost. For high-precision or complex components, hybrid workflows that combine staged machining with stress relief are often the most reliable solution. Careful planning, informed by material behavior and part geometry, remains the key to consistent and accurate results.