Are you struggling to decide which machining process is right for your manufacturing needs? Plain milling might be the answer to your production challenges, offering exceptional versatility and precision at competitive costs.

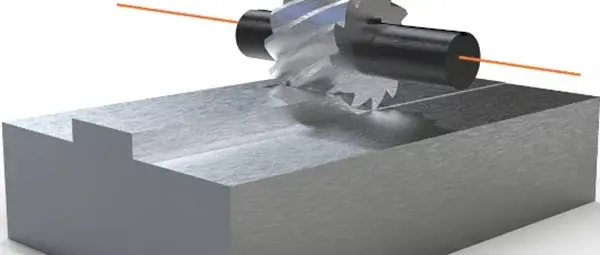

Plain milling is a machining process that uses a rotating multi-tooth cutter to remove material from a workpiece, creating flat surfaces. Modern CNC plain milling offers exceptional control, allowing for precise material removal in a single setup with repeatability that makes it ideal for both prototype and production runs.

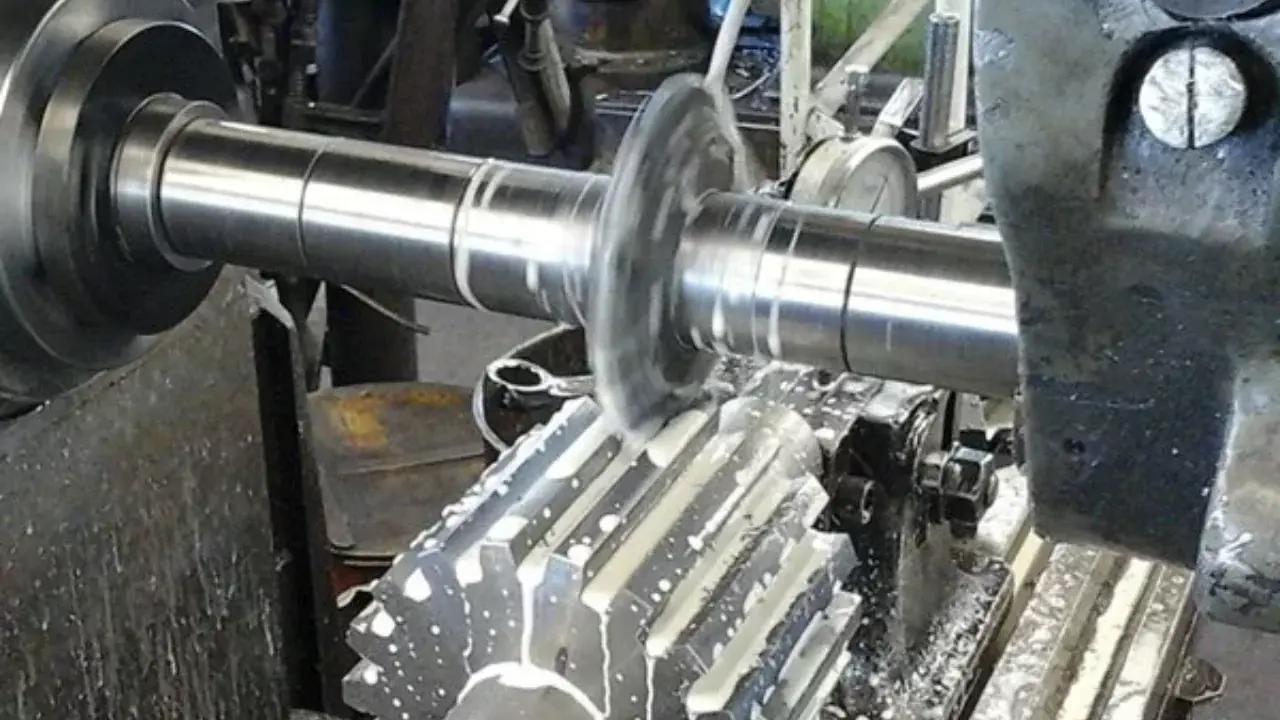

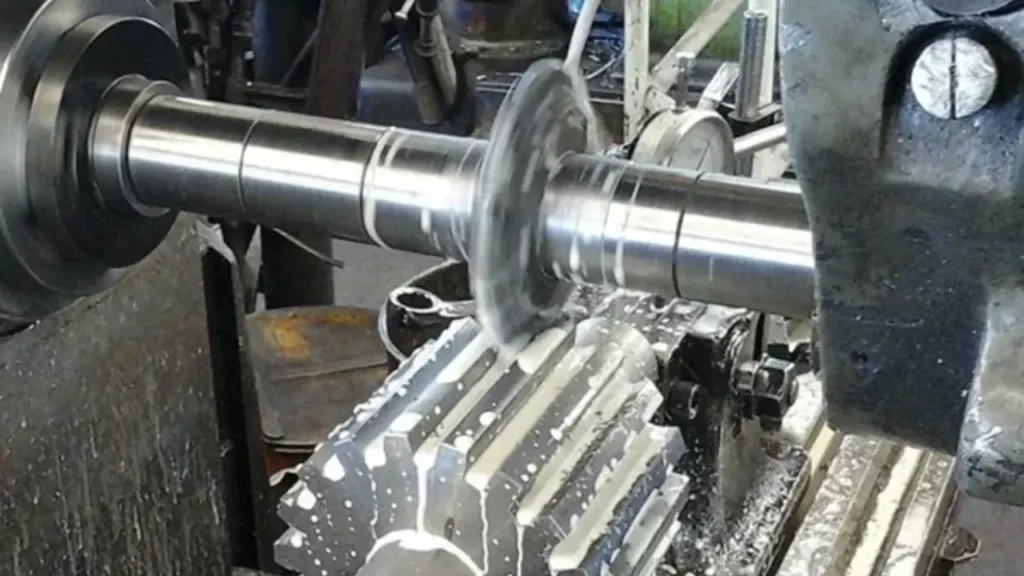

CNC plain milling process showing a horizontal cutter

As someone who has operated a CNC machining facility for years, I've seen firsthand how plain milling transforms raw materials into precise components. Let me walk you through everything you need to know about this fundamental machining process and how it might benefit your next project.

What materials work best with plain milling?

Is your project material giving you headaches with other machining methods? Plain milling excels with a wide range of materials, potentially solving your manufacturing challenges while maintaining tight tolerances.

Plain milling works exceptionally well with metals like aluminum, steel, brass, and copper, as well as plastics and composites. The process is particularly effective for materials that require flat, parallel surfaces with consistent dimensions, making it ideal for components that need precise mounting faces or reference surfaces.

Different materials are being processed through plain milling

Plain milling truly shines when matching the right material with the appropriate cutting parameters. In our factory, we've optimized parameters for dozens of materials through years of experience. Aluminum is perhaps the most forgiving material for plain milling, allowing for high speeds and excellent surface finishes. We typically run aluminum at cutting speeds 3-5 times faster than steel, which dramatically improves production efficiency.

Steel presents more challenges but responds well to modern carbide tooling. I remember a recent project where we plain-milled 304 stainless steel components for a medical equipment manufacturer. By selecting the right cutting tools with appropriate coatings and optimizing the feed rates, we achieved mirror-like surface finishes of Ra 0.8μm while maintaining ±0.02mm tolerances.

Plastics require special consideration due to their tendency to melt under excessive heat. We've developed specific protocols for engineering plastics like PEEK and Delrin, using specialized cutters and cooling strategies to prevent thermal deformation. For composites like carbon fiber, we use diamond-coated tools to manage the abrasive nature of these materials.

| Material Type | Cutting Speed (Relative) | Tool Requirements | Special Considerations |

|---|---|---|---|

| Aluminum | High (100%) | HSS or Carbide | Excellent machinability |

| Steel | Medium (30-40%) | Carbide preferred | Heat management critical |

| Stainless Steel | Low (20-30%) | Coated carbide | Coolant essential |

| Plastics | Medium-High (60-80%) | Sharp tooling | Temperature control |

| Composites | Low-Medium (30-50%) | Diamond or specialized coatings | Dust extraction needed |

How does plain milling compare to other CNC processes?

Wondering if plain milling is the right choice among the many machining options available? Understanding its strengths compared to other processes could save you time, money, and production headaches.

Plain milling excels at creating flat, parallel surfaces efficiently, while processes like turning handle cylindrical parts and 3D milling tackles complex contours. Plain milling offers a sweet spot of versatility, precision, and cost-effectiveness that makes it ideal for components requiring flat features and tight dimensional tolerances.

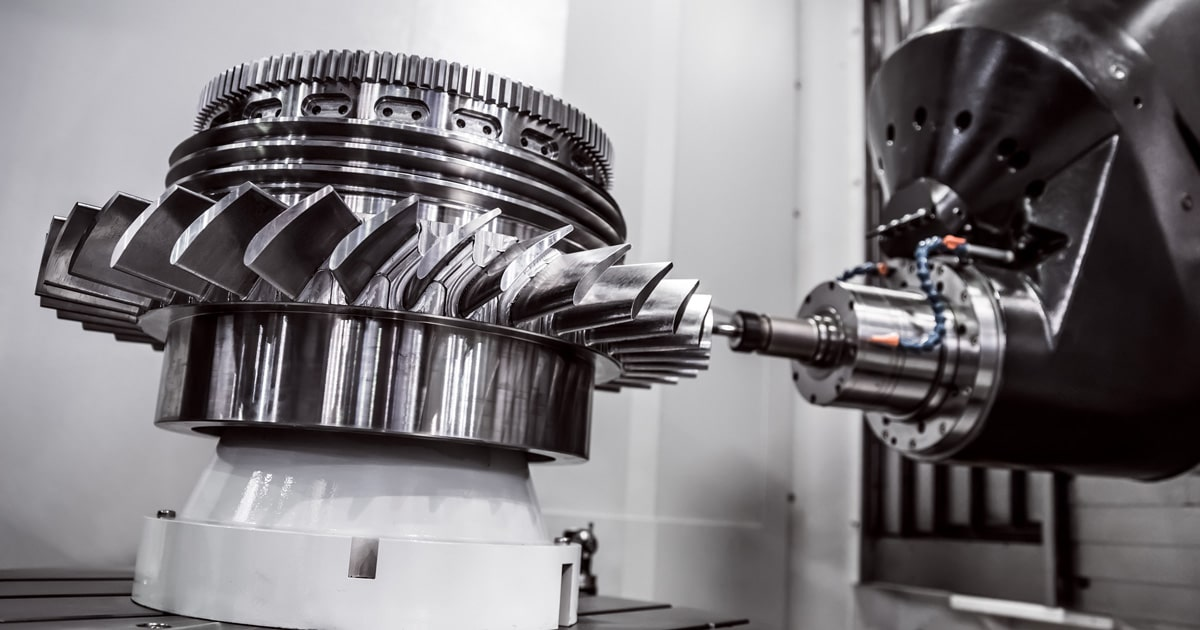

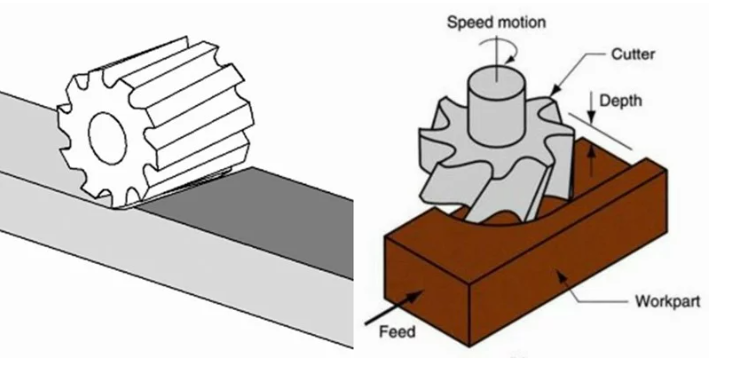

Visual comparison between plain milling and other CNC processes

From my experience running multiple CNC operations, plain milling holds distinct advantages that aren't immediately obvious until you've worked across different machining disciplines. The primary benefit of plain milling compared to turning operations is its ability to create precise flat surfaces with exceptional parallelism. While a lathe excels at creating cylindrical features, it simply cannot match a milling machine's capability for flat surfaces.

Compared to EDM (Electrical Discharge Machining), plain milling offers significantly faster material removal rates. I once had a customer switch a component from wire EDM to our plain milling process, reducing production time by 75% while maintaining similar tolerances. The trade-off was slightly different surface characteristics, but for their application, the cost savings justified the change.

When compared to 3D contouring operations, plain milling offers simpler programming and typically faster cycle times for components with primarily flat features. We recently produced a series of mounting plates that required extremely flat surfaces but minimal contoured features. By emphasizing plain milling operations instead of full 3D machining, we reduced cycle time by nearly 40%.

| Process | Best For | Relative Cost | Speed | Surface Finish | Typical Tolerances |

|---|---|---|---|---|---|

| Plain Milling | Flat surfaces, slots | Medium | Medium-Fast | Good | ±0.025mm |

| Turning | Cylindrical features | Low-Medium | Fast | Very Good | ±0.025mm |

| EDM | Complex shapes, hardened materials | High | Slow | Excellent | ±0.010mm |

| 3D Milling | Complex contours, organic shapes | High | Slow | Good-Excellent | ±0.025mm |

| Grinding | Very precise flat surfaces | High | Very Slow | Excellent | ±0.005mm |

What industries rely most on plain milling services?

Does your industry demand precision components with consistent quality? Plain milling serves as a backbone manufacturing process for sectors where dimensional accuracy and surface quality cannot be compromised.

Plain milling is essential in aerospace for structural components, automotive manufacturing for engine parts, medical device production for instrument components, and semiconductor equipment for precision mounting plates. Any industry requiring flat, parallel surfaces with tight tolerances relies heavily on plain milling capabilities.

Components made through plain milling for different industries

In my two decades of machining experience, I've witnessed the critical role plain milling plays across diverse industries. The aerospace sector represents one of the most demanding applications, where we regularly produce structural components requiring extremely tight tolerances. For these applications, we utilize our highest-precision machines with thermal compensation systems to maintain dimensional stability throughout the milling process.

The automotive industry leverages plain milling extensively for cylinder heads, engine blocks, and transmission cases. One particular automotive project involved milling mounting surfaces for a high-performance engine management system, where flatness tolerances were critical for proper heat transfer. Using specialized fixturing and cutting strategies, we achieved flatness within 0.015mm across a 300mm surface.

Semiconductor equipment manufacturing presents unique challenges that plain milling addresses effectively. We've produced hundreds of vacuum chamber components where large flat surfaces must maintain exceptional flatness for proper sealing. These aluminum and stainless steel components often require surface finishes of Ra 0.4μm or better with flatness tolerances measured in microns rather than thousandths.

The medical industry relies on plain milling for surgical instruments, implant manufacturing equipment, and diagnostic devices. The combination of precise flat surfaces and biocompatible materials like titanium and specific grades of stainless steel makes plain milling indispensable for these applications.

| Industry | Common Applications | Material Preferences | Typical Tolerances | Special Requirements |

|---|---|---|---|---|

| Aerospace | Structural components, fixtures | Aluminum, titanium, specialized alloys | ±0.010mm | Material certifications, traceability |

| Automotive | Engine blocks, transmission cases | Cast iron, aluminum, steel | ±0.025mm | High volume capability |

| Semiconductor | Vacuum chambers, mounting plates | Aluminum, stainless steel | ±0.012mm | Exceptional flatness, cleanliness |

| Medical | Surgical instruments, implant fixtures | Titanium, medical-grade stainless | ±0.015mm | Biocompatibility, documentation |

| Marine | Propulsion components, fittings | Bronze, stainless steel, composites | ±0.050mm | Corrosion resistance |

What tolerances can be achieved with modern CNC plain milling?

Are you concerned about meeting strict dimensional requirements for your components? Today's CNC plain milling technology delivers precision that rivals specialized processes at a fraction of the cost.

Modern CNC plain milling machines regularly achieve tolerances of ±0.025mm (0.001") and surface finishes as fine as Ra 0.8μm under optimal conditions. These capabilities are possible thanks to advanced machine construction, thermal compensation systems, high-precision spindles, and sophisticated CNC controls that ensure consistent results.

Precision measurement of a plain milled surface showing tight tolerances

Having invested heavily in advanced CNC equipment over the years, I can attest to the remarkable precision now possible with modern plain milling. Our newest machines incorporate linear glass scales with resolution down to 0.0001mm, allowing us to consistently hold dimensional tolerances of ±0.015mm on production runs. This level of precision was once the exclusive domain of grinding operations.

Temperature control plays a crucial role in achieving ultimate precision. Our climate-controlled facility maintains temperature within ±1°C, and our most precise machines incorporate thermal compensation systems that automatically adjust for minute thermal expansions in both the machine structure and the workpiece. I recall a challenging project for a semiconductor client where we maintained ±0.008mm tolerances across 500mm aluminum plates by implementing a specialized thermal management protocol.

Cutting tool technology has advanced dramatically as well. Modern carbide end mills with specialized coatings and geometries allow us to achieve surface finishes that were previously impossible. Through careful selection of cutting parameters and toolpaths, we regularly produce surfaces with roughness values below Ra 0.4μm directly from the milling process, eliminating secondary operations.

Workholding techniques significantly impact achievable tolerances. We utilize vacuum fixtures, precision vises, and custom fixturing systems to minimize workpiece distortion during machining. For extremely precise applications, we sometimes employ in-process probing to verify dimensions before completing critical features, allowing for adjustments to compensate for tool wear or thermal effects.

| Tolerance Level | Typical Applications | Requirements for Achievement | Cost Implication |

|---|---|---|---|

| Standard (±0.05mm) | General components, non-critical surfaces | Standard CNC mill, skilled operation | Base cost |

| Precision (±0.025mm) | Mating surfaces, reference features | Temperature-controlled environment, quality tooling | 20-30% premium |

| High-precision (±0.010mm) | Critical mounting features, sealing surfaces | High-end machine, thermal compensation, in-process measurement | 50-80% premium |

| Ultra-precision (±0.005mm) | Optical components, gauge surfaces | Specialized machines, controlled environment, advanced fixturing | 100%+ premium |

Conclusion

CNC plain milling offers exceptional precision, material versatility, and cost-effectiveness for components requiring flat surfaces. With modern equipment capable of micron-level tolerances, it remains essential across manufacturing industries despite newer technologies.