In CNC machining, accuracy alone is not enough. For many customers, especially in regulated industries, inspection documentation is what turns a machined part into an approved part. These records show that dimensions were verified, materials were correct, and processes followed the approved specifications.

Quality Control and Inspection for CNC Machining

Inspection documentation exists to protect everyone involved. It gives OEMs confidence in supplier capability, helps CNC shops pass audits, and ensures end users receive parts that meet safety and performance requirements. This article explains the most common inspection documents used in CNC machining, including First Article Inspection Reports, PPAP documentation, Certificates of Conformance, and material reports.

Why Inspection Documentation Is Critical in Regulated CNC Manufacturing

In regulated CNC manufacturing, inspection documentation is not an administrative formality. It is a core control mechanism that determines whether a part is acceptable for use, shipment, or installation. OEMs rely on inspection records to confirm that suppliers followed approved drawings, materials, and processes. For CNC shops, these documents demonstrate process discipline and technical credibility long before a physical audit takes place.

Inspection documentation also acts as a shared reference point between engineering, quality, procurement, and compliance teams. When questions arise about part performance, fit, or safety, inspection records provide objective evidence. They reduce ambiguity, shorten approval cycles, and help prevent disputes that can otherwise stall production or damage supplier relationships.

How Inspection Records Protect OEMs, Suppliers, and End Users

At its core, inspection documentation creates accountability across the supply chain. For OEMs, it confirms that purchased parts meet defined requirements before they are integrated into assemblies or systems. For CNC suppliers, it proves compliance and protects against liability claims when issues occur outside their control. End users benefit because documented verification reduces the risk of field failures, recalls, or safety incidents.

Quality Inspection And Quality Control For CNC Machining

Proper inspection records also support traceability. If a nonconformance is discovered, documentation allows manufacturers to identify affected batches, materials, or process steps quickly. This limits the scope of corrective actions and prevents unnecessary scrap or recalls.

Relationship Between Documentation, Audits, and Part Approval

Audits in regulated industries focus as much on documentation as on machining capability. During customer or third-party audits, inspectors rarely rely on verbal explanations. They review inspection reports, material certificates, and revision histories to confirm that systems are working as intended.

Part approval is directly tied to documentation quality. Even when parts meet dimensional requirements, missing or inconsistent records can delay approval. In many cases, OEMs will not release payment or authorize production ramps until documentation packages are reviewed and accepted. Strong documentation practices reduce these approval bottlenecks and signal supplier maturity.

Consequences of Missing or Incorrect Documentation

The absence of proper inspection documentation carries real operational and financial risks. Common consequences include:

- Production delays while missing records are recreated or reverified

- Rejected lots due to incomplete or inconsistent inspection data

- Increased scrutiny during audits, leading to corrective action requests

- Loss of approved supplier status for repeat documentation failures

In regulated environments, these issues often escalate quickly. A single documentation lapse can trigger broader audits or temporary sourcing freezes.

Industry Expectations Across Key Sectors

Although inspection principles are similar, documentation expectations vary by industry based on risk and regulatory exposure.

Aerospace

Aerospace manufacturers expect full traceability and strict revision control. First Article Inspection Reports aligned with AS9102 are standard. Documentation must clearly link every measured characteristic to the approved drawing revision and material source.

Automotive

Automotive OEMs emphasize process consistency and repeatability. PPAP documentation is used to validate that CNC processes can produce parts at volume without variation. The focus extends beyond initial inspection to long-term process control.

Medical

Medical device manufacturing prioritizes risk management and patient safety. Documentation supports ISO 13485 compliance and demonstrates that every part can be traced back to approved materials and validated processes. Inspection records are critical for regulatory reviews and post-market investigations.

Across all three sectors, inspection documentation is not optional. It is a prerequisite for trust, approval, and long-term manufacturing partnerships.

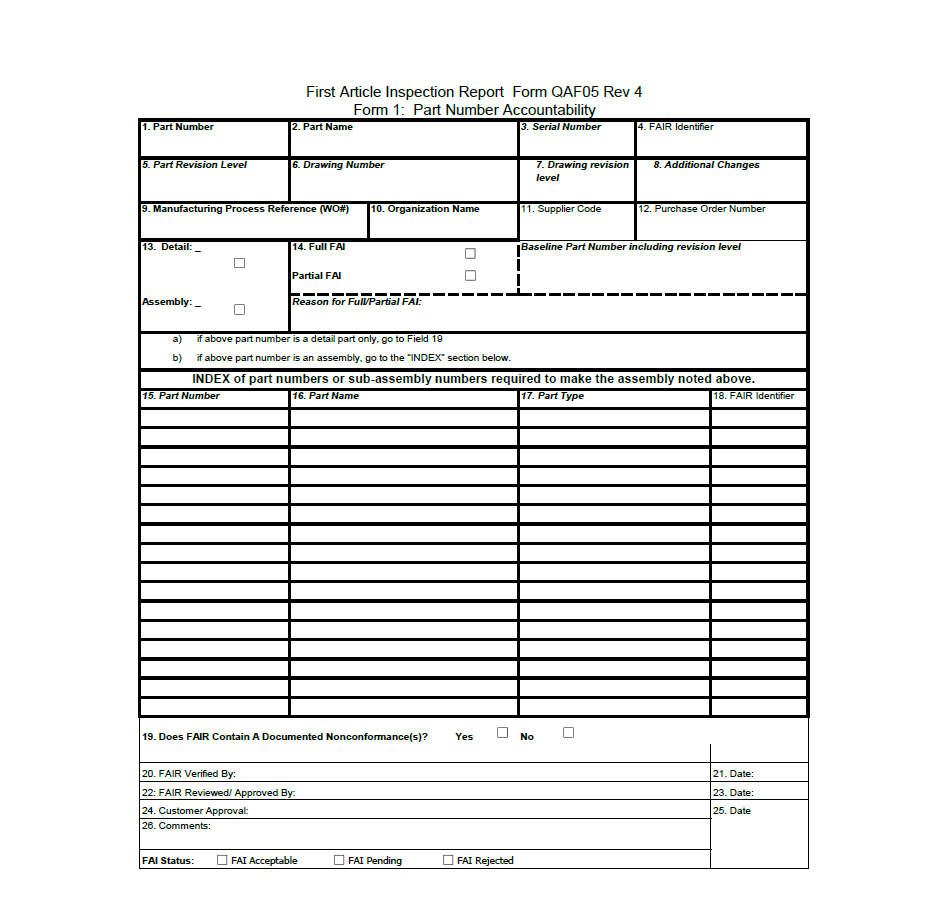

First Article Inspection Report (FAIR): Purpose, Structure, and Use Cases

A First Article Inspection Report is often the first formal quality checkpoint between a CNC supplier and the customer. It verifies that a newly produced part fully conforms to the engineering drawing, specifications, and contractual requirements before regular production begins. Unlike routine inspection records, a FAIR establishes a documented baseline that future production runs are measured against.

In regulated manufacturing, an FAIR is not simply a dimensional report. It is evidence that the supplier understands the design intent, has controlled the manufacturing process, and can reproduce the part consistently. Customers rely on FAIRs to reduce risk before approving ongoing production or releasing larger purchase orders.

What a First Article Inspection Report Proves

A FAIR confirms that the first production part meets all defined requirements. This includes geometry, tolerances, materials, finishes, and special processes. More importantly, it proves that the manufacturing process is capable, repeatable, and aligned with the approved documentation.

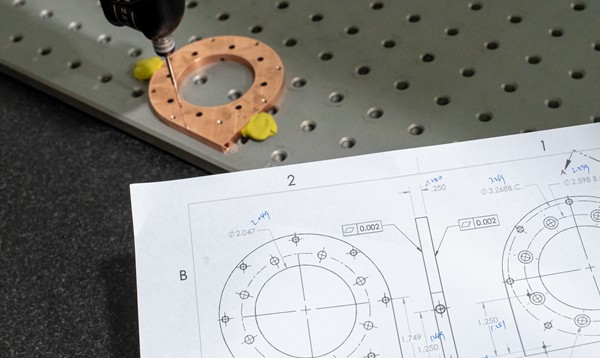

Sample First Article Inspection Form

For OEMs, a complete FAIR reduces uncertainty. It shows that the supplier has validated tooling, programs, inspection methods, and documentation control. For CNC shops, it provides a formal record that protects against future disputes related to design interpretation or process changes.

When a FAIR Is Required

FAIRs are typically required at specific points in the product lifecycle. Common triggers include the initial release of a new part and any change that could affect form, fit, or function. Customers often specify these requirements clearly in purchase orders or quality agreements.

Typical situations that require a new or partial FAIR include:

- Introduction of a new part number

- Design changes, such as tolerance updates or geometry modifications

- Process changes involving machines, tooling, fixtures, or suppliers

Even minor changes can require a FAIR if they impact critical characteristics. Clear communication with the customer is essential to determine the expected scope.

Key Elements of a FAIR

A well-prepared FAIR follows a structured format that links inspection results directly to the engineering drawing. This structure ensures clarity and audit readiness.

The most critical elements include:

- Ballooned drawings with unique characteristic numbers for every requirement

- Dimensional inspection results for all features, including notes and callouts

- Verification of material type, heat number, and required processes

- Confirmation of part number, drawing revision, and configuration

Each result must be clearly traceable. Ambiguous entries or missing references often lead to rejection, even when measurements are within tolerance.

FAIR in Aerospace Versus Other Industries

While FAIRs are used across industries, aerospace applies the most rigorous expectations. Aerospace customers typically require compliance with AS9102 principles, which mandate complete traceability and standardized reporting. Every characteristic must be accounted for, including notes, specifications, and process requirements.

This level of detail exists because aerospace components operate in high-risk environments. Failures can have severe consequences, so documentation must support long-term confidence. Outside of aerospace, FAIR formats may be simpler, but the underlying purpose remains the same. A strong FAIR demonstrates control, capability, and readiness for sustained production.

By establishing a verified baseline, FAIRs reduce future inspection burden and create a clear reference point for both suppliers and customers throughout the product lifecycle.

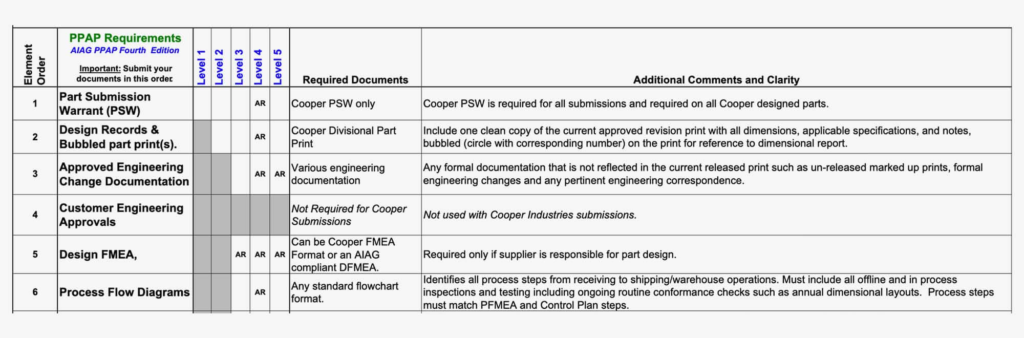

PPAP Documentation in Automotive CNC Manufacturing

In automotive CNC manufacturing, part approval extends beyond dimensional accuracy. OEMs need assurance that a supplier can produce the same part repeatedly, at volume, without variation. The Production Part Approval Process, commonly referred to as PPAP, exists to provide that confidence. It validates not only the part but also the manufacturing process, inspection systems, and quality controls behind it.

Production Part Approval Process

PPAP shifts the focus from one-time inspection to long-term process reliability. For CNC shops supplying automotive components, PPAP documentation is often mandatory before production orders are released. It demonstrates that machining programs, fixtures, tooling, and inspection methods are stable and capable of meeting requirements over time.

What Production Part Approval Process Means

PPAP is a structured documentation package used by automotive OEMs and Tier 1 suppliers to approve production parts. Its primary purpose is to confirm that all engineering requirements are understood and that the manufacturing process can consistently produce conforming parts under normal operating conditions.

Unlike a FAIR, which validates the first part, PPAP evaluates the entire production system. It addresses how parts are made, inspected, and controlled throughout their lifecycle. This broader scope reflects the high-volume nature of automotive manufacturing.

Why Automotive OEMs Require PPAP for CNC Parts

Automotive programs often involve large quantities, tight tolerances, and strict delivery schedules. A single quality issue can affect thousands of vehicles. PPAP reduces this risk by requiring suppliers to prove process capability before full production begins.

For OEMs, PPAP documentation provides confidence in:

- Process consistency across shifts and production batches

- Measurement systems used for critical dimensions

- Supplier readiness for volume production

For CNC shops, PPAP approval establishes credibility and opens the door to long-term contracts.

Core PPAP Elements Relevant to CNC Shops

While PPAP includes many possible elements, certain components are particularly relevant to CNC machining operations. These documents connect engineering intent to shop floor execution.

Key elements commonly required include:

- Design records and documentation of approved engineering changes

- Process flow diagrams showing each machining and inspection step

- Control plans defining how critical characteristics are monitored

- Measurement system analysis to validate inspection repeatability

- Initial sample inspection results for production parts

The depth of each element depends on customer requirements and part criticality.

PPAP Levels and Practical Impact

PPAP submissions are categorized into different levels, typically ranging from Level 1 to Level 5. Each level defines the amount of documentation that must be submitted to the customer.

Lower levels may require only limited documentation, such as a warrant and sample parts. Higher levels demand full documentation packages and on-site reviews. The required level is usually specified by the customer and influenced by factors such as part complexity, safety impact, and supplier history.

As risk increases, so does documentation depth. Understanding these expectations early helps CNC shops plan inspection activities, allocate resources, and avoid approval delays. When managed correctly, PPAP becomes a structured pathway to stable, repeatable production rather than an administrative burden.

Certificates of Conformance and Material Test Reports

Once parts move into regular production, daily inspection documentation becomes just as important as first article or PPAP records. Certificates of Conformance and material test reports are the documents most commonly reviewed at shipment. They confirm that each delivered batch meets contractual and regulatory requirements, even when full inspection data is not requested.

These documents often travel with every order. For many customers, especially in aerospace and medical manufacturing, a shipment without proper certificates is considered incomplete. Understanding their purpose and limitations helps CNC suppliers provide the right level of documentation without unnecessary complexity.

Certificate of Conformance and Its Role in CNC Production

A Certificate of Conformance, commonly referred to as a COC, is a formal declaration by the CNC supplier that the delivered parts conform to all specified requirements. It does not list individual measurements. Instead, it confirms that inspections were performed and that results met the approved criteria.

Certificate of Conformance sample

A typical COC includes key identifiers that link the shipment to approved documentation and inspections. This usually covers:

- Supplier name and manufacturing location

- Part number and revision level

- Purchase order reference and quantity shipped

- Statement of conformity signed by an authorized representative

For repeat production with stable processes, a COC is often sufficient. Customers rely on the supplier’s quality system to ensure ongoing compliance.

When a COC Is Sufficient Without Full Inspection Data

Not every shipment requires detailed inspection reports. In many cases, especially for noncritical components or established programs, a COC provides the right balance between assurance and efficiency.

COCs are commonly accepted when:

- The part has an approved FAIR or PPAP on file

- No design or process changes have occurred

- The supplier has a strong quality history with the customer

However, customers may still request supporting inspection data during audits or investigations. The COC works best when backed by well-maintained internal records.

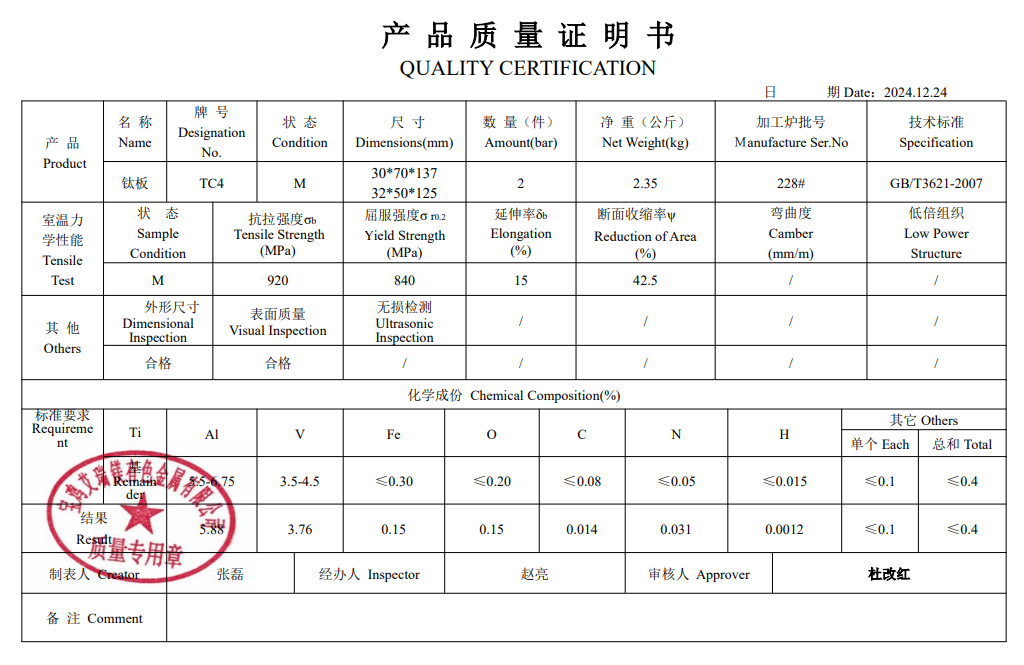

Material Test Reports and What They Verify

Material test reports, also known as mill certificates or MTRs, provide verification of raw material properties. These reports confirm that the material used in CNC machining meets the specified grade, chemistry, and mechanical requirements.

An MTR typically includes:

- Material grade and specification standard

- Heat or batch number for traceability

- Chemical composition results

- Mechanical property values such as tensile strength and hardness

These reports are issued by the material supplier and form the foundation of material traceability.

Importance of Material Traceability in Aerospace and Medical Parts

In aerospace and medical manufacturing, material traceability is nonnegotiable. MTRs link finished parts back to the original material source, enabling rapid investigation if issues arise. This traceability supports regulatory compliance and limits exposure during recalls or corrective actions.

For CNC shops, maintaining accurate material documentation is essential. Heat numbers must be preserved through machining, inspection, and packaging. When combined with COCs, material test reports complete the documentation chain that proves both process and material conformity.

Together, COCs and MTRs ensure that every shipped part is supported by clear, verifiable evidence. They form the backbone of daily quality assurance in professional CNC manufacturing operations.

How CNC Shops Prepare and Manage Inspection Documentation

Behind every accepted inspection document is a structured internal workflow. Professional CNC shops treat documentation as an integrated part of production rather than a task added at the end. Inspection planning, data collection, and record control are aligned with machining operations to ensure accuracy, consistency, and audit readiness.

Product Quality Inspection Control Process

Effective documentation management reduces rework and approval delays. It also allows quality teams to respond quickly to customer questions, audits, or nonconformance investigations. The goal is to create reliable records without slowing down production.

Inspection Planning and Data Collection

Inspection documentation begins long before the first part is measured. Quality teams review drawings, specifications, and customer requirements to define inspection methods and acceptance criteria. This planning ensures that critical characteristics are identified and verified correctly.

Data collection typically combines automated and manual methods depending on part complexity. Common practices include:

- CMM inspection for complex geometry and tight tolerances

- Manual inspection using calibrated tools for simpler features

- In process checks to catch variation early

- Final inspection to confirm shipment readiness

Clear inspection plans reduce ambiguity and improve repeatability across shifts and operators.

Revision Control and Drawing Management

Accurate documentation depends on strict revision control. CNC shops must ensure that machining, inspection, and reporting are all based on the same drawing revision. Using outdated documents is a common cause of rejected inspection packages.

Effective revision control includes controlled access to drawings, clear identification of current revisions, and documented approval of changes. When revisions occur, inspection records must clearly indicate which version was used.

Documentation Control Systems

As documentation volume increases, manual record-keeping becomes inefficient and risky. Many CNC shops rely on digital systems to manage inspection data and certificates. These systems improve accessibility and reduce errors.

Typical tools include:

- Digital inspection report templates

- ERP systems linked to work orders and shipments

- Quality management systems for record retention

Well-integrated systems support audit readiness by allowing rapid retrieval of historical records.

Best Practices for OEM-Approved CNC Suppliers

CNC suppliers that consistently meet documentation expectations follow disciplined practices. They standardize formats, maintain clarity, and communicate proactively with customers.

Best practices include:

- Using consistent templates for FAIRs, PPAPs, and COCs

- Applying clear naming conventions and version tracking

- Reviewing documentation internally before submission

- Clarifying documentation scope with customers upfront

When documentation is treated with the same rigor as machining accuracy, it becomes a competitive advantage. Strong documentation practices build confidence, reduce friction, and support long-term supplier relationships.

Conclusion

In regulated CNC manufacturing, inspection documentation carries the same weight as machining precision. FAIRs, PPAP packages, Certificates of Conformance, and material test reports provide objective proof that parts meet design, material, and process requirements. Without these records, even accurately machined components can face delays, rejections, or loss of approval.

Strong documentation practices protect OEMs and suppliers alike. They reduce risk, support audits, and create confidence in long-term production capability. CNC shops that invest in clear, controlled, and consistent inspection documentation position themselves as reliable partners rather than just capable manufacturers.