Protecting Your Wooden Beach Chair from the Sun: A Guide to Durable UV Protection?

Love your wooden beach chair? The sun might not! UV rays can ruin it fast. To protect your wooden beach chair from the sun, use

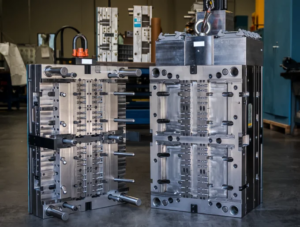

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

Love your wooden beach chair? The sun might not! UV rays can ruin it fast. To protect your wooden beach chair from the sun, use

Are you worried about the strength of your welded products? Welding porosity can cause significant problems. It may be an invisible issue, but it can

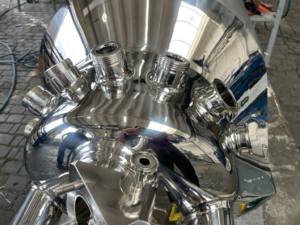

A vacuum chamber removes gas particles to create controlled environments for manufacturing and testing. Have you ever struggled with contamination during thin-film coating processes? What

Polishing is an operation that creates a smooth, shiny surface finish by softening the surface layer and smearing through frictional heating. The process is combined with fine-scale abrasive removal to improve the appearance and function of the material.

Mirror polishing is an important activity in many different industries such as manufacturing, automotive, and optics. This process involves reducing surface flaws, which increases reflectivity and improves the surface quality, aesthetics, and functionality of the object. Actually, the grading system from A0 to A3 is a classification of different levels of mirror finishes, with A0 being the highest grade.

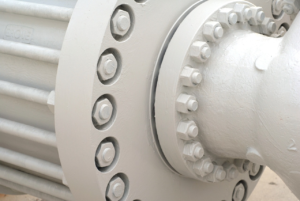

Maintaining gaskets and flanges is crucial for pipe system function and drilling. Regular inspections, proper gasket selection & fitting, cleanliness, and bolt maintenance prevent common issues. Pressure tests and timely replacements of worn parts prevent leaks, maximize usability, extend lifespan, and reduce costly repairs.

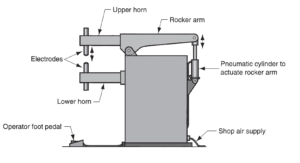

Resistance Spot Welding (RSW): Process Overview Resistance Spot Welding is a process wherein the faying surfaces of a lap joint are joined by applying pressure

Do you work in construction, oil and gas, or another industry? I’m pretty sure you’ll agree that pipes are crucial components. However, piping systems rarely

When we think about welding, the first image that likely comes to mind is the bright sparks and molten metal used to join steel or

Industry systems require various components and one of them is a flange accessory. Flange accessories act as important elements in establishing strong and reliable connections

In modern production, electroplating is an essential procedure that unites durability, utility, and beauty. It is crucial in high-tech sectors including aerospace, electronics, automotive, and healthcare, and it may improve conductivity and corrosion resistance in addition to offering aesthetically pleasing surfaces.

Flange connections are essential in various industries. The choice of the appropriate method relies on considerations such as pressure, temperature, maintenance, and cost. Welded flanges are strong and reliable for systems with high pressure. Bolted flanges are easy to maintain and replace. Threaded flanges work well for low-pressure and portable setups. Lap joint flanges offer flexibility, and blind flanges are perfect for sealing systems.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.