The growing demands of electrical conductivity, thermal management, and corrosion resistance have left many manufacturers struggling to find suitable materials. Copper alloys offer solutions to these challenges, but only when machined with precision.

Copper alloys are essential in modern manufacturing because they combine excellent electrical conductivity with impressive thermal properties and corrosion resistance. When precision-machined using CNC technology, copper components deliver superior performance in applications ranging from electrical systems to marine environments, making them irreplaceable in today's industrial landscape.

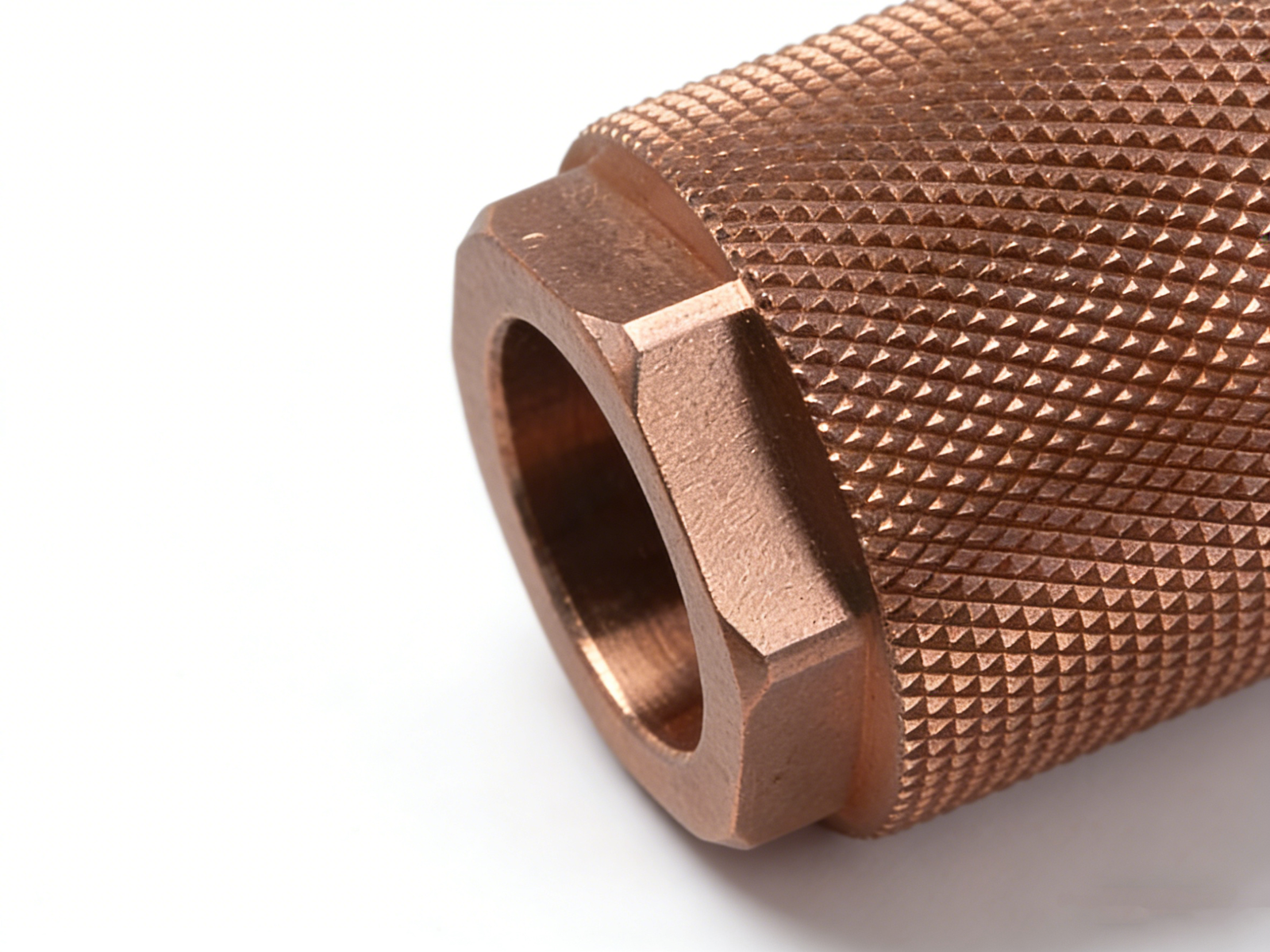

Precision CNC-machined copper components

In our decades of manufacturing experience, we've seen copper alloys become increasingly important across multiple industries. As technology advances, the demand for precisely machined copper components has grown substantially. Let me share what we've learned about working with these versatile metals.

How Do Copper's Unique Properties Affect Precision Machining Processes?

Machinists often struggle with copper's tendency to be gummy and stick to cutting tools, causing poor surface finishes and tool wear. Without proper techniques, these challenges can lead to rejected parts and increased costs.

Copper's excellent thermal conductivity requires specific machining approaches, including proper cooling strategies and cutting parameters. The material's ductility means using sharp cutting tools, moderate cutting speeds (typically 300-500 SFM), and generous amounts of lubricant to prevent material buildup on tool edges, ensuring smooth cuts and preventing work hardening.

Copper machining process showing coolant application

Copper presents a fascinating paradox in the machining world. While its softness might suggest easy machinability, its high thermal conductivity and ductility create unique challenges that demand specialized approaches. In our shop, we've developed several techniques to overcome these inherent difficulties.

For successful copper machining, tool selection becomes critical. We typically use high-speed steel (HSS) or carbide tools with positive rake angles between 5-15 degrees to slice through the material rather than push into it. This reduces the "gummy" behavior copper is known for. Cutting speeds must be carefully controlled—too fast and tools wear prematurely, too slow and the material smears rather than cuts cleanly.

Cooling strategies are equally important due to copper's excellent thermal conductivity. Unlike some metals, where heat concentrates near the cutting edge, copper quickly dissipates heat throughout the workpiece. We employ flood coolant systems that direct lubricant precisely at the cutting interface. In some high-precision applications, we've found that oil-based coolants outperform water-based solutions by providing better lubricity.

| Machining Parameter | Recommended Range for Copper | Impact on Process |

|---|---|---|

| Cutting Speed | 300-500 SFM | Prevents material smearing |

| Feed Rate | 0.003-0.010 in/rev | Controls chip formation |

| Tool Rake Angle | 5-15 degrees positive | Reduces material buildup |

| Coolant Type | Oil-based preferred | Improves lubricity |

| Tool Material | HSS or Carbide | Maintains sharp edge |

Which Copper Alloys Provide Optimal Performance for CNC-Manufactured Parts?

Engineers often face analysis paralysis when selecting from dozens of copper alloys, each with different properties. Without clear guidance, they risk choosing materials that underperform or exceed budget constraints unnecessarily.

The optimal copper alloy depends on the application's specific requirements. C110 (ETP Copper) offers maximum electrical conductivity for power transmission components. C360 (Free-Cutting Brass) provides excellent machinability for high-volume production. For marine environments, C71500 (Copper-Nickel) delivers superior corrosion resistance, while bronze alloys like C54400 offer strength with moderate conductivity.

Selection of common copper alloys used in CNC machining

Through years of manufacturing experience, I've found that selecting the right copper alloy can make the difference between a component that merely functions and one that excels in its application. Each copper alloy offers a unique combination of properties that must be carefully matched to the intended use.

Electrical and electronic applications typically benefit most from C101 (Oxygen-Free Copper) and C110 (Electrolytic Tough Pitch). These alloys provide conductivity values approaching 100% IACS (International Annealed Copper Standard), making them ideal for high-current applications. However, their relatively low strength means they aren't suitable for components under mechanical stress.

For applications requiring both strength and conductivity, beryllium copper alloys like C17200 offer an excellent compromise. With conductivity around 22% IACS and tensile strengths exceeding 200,000 psi after heat treatment, these alloys excel in spring contacts, bearings, and non-sparking tools. However, they require careful handling during machining due to the toxic nature of beryllium.

Brass alloys, particularly C360 and C353, have earned their reputation as the workhorses of the copper alloy family. Their lead content (though being reduced due to environmental regulations) creates a natural chip breaker effect during machining. We've found these alloys particularly cost-effective for high-volume production runs where machinability directly impacts manufacturing costs.

| Alloy Designation | Composition | Key Properties | Best Applications |

|---|---|---|---|

| C110 (ETP) | 99.9% Cu | Highest conductivity (100% IACS) | Electrical conductors, terminals |

| C360 Brass | 61.5% Cu, 35.5% Zn, 3% Pb | Excellent machinability | Valves, fittings, decorative hardware |

| C17200 Beryllium Copper | 98% Cu, 1.9% Be | High strength, good conductivity | Springs, surgical instruments |

| C71500 Copper-Nickel | 70% Cu, 30% Ni | Superior corrosion resistance | Marine components, heat exchangers |

| C54400 Phosphor Bronze | 88% Cu, 10% Sn, 2% P | Good strength and wear resistance | Bushings, gears, bearings |

When Should Engineers Choose Copper Over Other Metals for CNC Components?

Design engineers frequently default to aluminum or steel based on familiarity rather than optimal performance. This oversight often results in components that fail to meet electrical, thermal, or corrosion requirements in demanding environments.

Engineers should choose copper when applications demand superior electrical conductivity (nearly twice that of aluminum), excellent thermal management (high conductivity with no galvanic issues), antimicrobial properties, or corrosion resistance in marine environments. Despite higher material costs, copper's performance advantages and longer service life often provide better overall value.

Material comparison showing copper, aluminum and steel parts

In my experience overseeing thousands of machining projects, the decision to use copper often comes down to a careful analysis of performance requirements against budget constraints. While copper typically commands a higher price than aluminum and some steels, its unique property profile often delivers superior long-term value.

Electrical applications present perhaps the clearest case for copper selection. With conductivity approximately 60% higher than aluminum by volume, copper allows for smaller cross-sections in power distribution components, saving space in compact designs. This becomes particularly important in applications like electric vehicles, where power density is crucial. We've manufactured numerous busbars and connectors where the performance difference between copper and aluminum justified the additional material cost.

Thermal management represents another area where copper excels. In heat sink applications, copper's thermal conductivity (approximately 385 W/m·K) far outperforms aluminum (about 205 W/m·K). For high-heat electronics and power systems, this difference can determine whether components operate within safe temperature ranges. One aerospace client switched from aluminum to copper heat exchangers after experiencing thermal throttling issues in their avionics systems.

Corrosion resistance provides another compelling reason to select copper, particularly in marine and chemical processing applications. Unlike stainless steels that can suffer from pitting and crevice corrosion in saltwater environments, copper-nickel alloys form a self-protecting patina that actually improves over time. This property makes copper alloys particularly valuable in seawater cooling systems and offshore equipment.

| Application Requirement | Copper Advantage | Example Components |

|---|---|---|

| Electrical Performance | Nearly 60% higher conductivity than aluminum | Busbars, terminals, connectors |

| Thermal Management | 1.8× better thermal conductivity than aluminum | Heat sinks, cooling plates, exchangers |

| Corrosion Resistance | Self-passivating in many environments | Marine fittings, chemical processing parts |

| Antimicrobial Properties | Naturally kills bacteria and viruses | Medical device components, touch surfaces |

| Aesthetic Value | Attractive appearance, patina development | Architectural elements, luxury goods |

Conclusion

Copper alloys deliver unmatched performance in electrical, thermal, and corrosive applications when precision-machined. By understanding copper's unique properties and selecting the right alloy, manufacturers can create components that outperform alternatives despite higher initial costs.