CNC machines are getting more popular day by day. From Transportation Industry to Aerospace, or Electronic Industry to the Marine, CNC machines make goods and products everywhere. Since the invention of the first CNC machine in 1951, these machines have evolved with technology over time, increasing their yield and efficiency, becoming better with each generation. Currently, the global market for CNC machines is USD 83.99 billion. By 2028, this market will grow to USD 128.41 billion, making it a member of the 100 billion industries club. The number clearly shows that the popularity of CNC machines will continue to grow in the coming years.

What is a CNC machine?

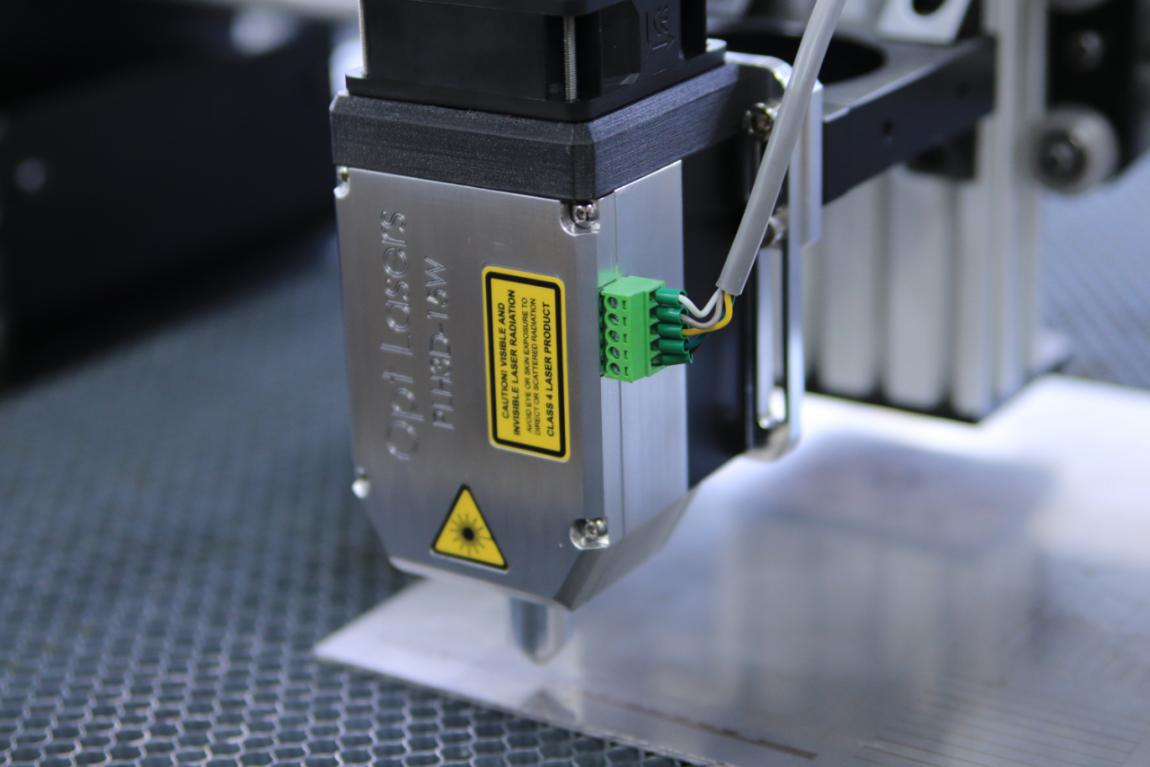

So, what is a CNC machine? CNC means Computerized Numerical Control. As the name suggests, these complex machines are computerized and controlled through a specific computer language, just like coding. Once you program it according to your need, it operates automatically without a manual operator. The programmed computer software will command the moving parts of the machinery, thereby automating the whole manufacturing process, saving time and money.

CNC machines and the Medical Industry

In medicine, using accurate and precise machines to produce medical instruments and devices is always much more crucial than in any other area. The reason is a no-brainer - Products are human beings or human lives. All the medical instruments or devices manufactured by any machine will be related to patient care. The possibility of error, whether mechanical or human, should be minimal or zero. Therefore, CNC machines are a popular and safer choice than manual machines. They are much more accurate and precise. In addition, computer programming and Artificial Intelligence make them way ahead of manual machines in the medical field.

Medical Instruments We Can Make From CNC Machines

CNC machines can manufacture all of the parts related to medicine. From simple surgical instruments such as forceps and scissors to complex medical implants like knee or hip replacements, they can make all of them. CNC machines can also make parts for complex medical equipment like X-ray machines and MRI scanners. Micro implantable devices like pacemakers, stents, catheters, and heart valves are also manufactured by CNC machines.

Role of CNC machines in COVID 19 Pandemic

Like the rest of the world, COVID-19 was a challenge for the medical world. Besides facing a shortage of medical staff like doctors and nurses, a shortfall of medical instruments and devices was a hurdle to providing the best patient care to people and controlling the pandemic.

In such a crisis, CNC machines proved a lifesaver for the world. They fulfilled the massive supply chain gap of the medical supplies in the market created by lockdowns and physical work restrictions. The automation technology of CNC machines controlled the situation, or else the scenario could have been worst and out of control.

Why CNC machining is in Demand in Medical Industry- A Deeper look into their Benefits.

Reasons for the popularity of CNC machines in the medical industry are increasing by each day. Here, we will talk about some of a few main highlights that make them the go-to option for manufacturing medical instruments and devices.

Endless Potential To produce Medical Goods.

Because CNC machines work on computer programming and automation processes to produce medical goods, there is no restriction on the volume of production. You can generate as many medical instruments and devices as you want with a single CAD file( Computer-Aided Design File - Digital 2D, 3D Model, or file of the medical tool to be manufactured). This aspect of the CNC machines is significant to the medical industry. It ensures that adequate medical supplies and instruments are available at all times.

For example, if there is an urgent need in a hospital for medical supplies due to any medical emergency, Only CNC machines can fulfill the demand in a short period. In addition, these parts built with high precision and accuracy are second to none. No other manual technique or other manufacturing machine is capable enough to produce a bulk of medical supplies at the last hour. In their case, you must notify the supplier or vendor days ahead. But that's not the situation with CNC machines, making them popular in the medical industry.

Flexibility and Innovation to Produce Medical Goods

CNC machines can produce custom parts and medical instruments. In this way, it opens and expands the horizon of research and innovation in the medical world. There is no fixed pattern or design to follow for producing medical instruments or tools using CNC machines. You always have an option to change or customize the design or production with a wide range of materials, like steel, zinc, copper, titanium or PVC, etc.

All these capabilities of CNC machines allow medical personnel to try and test different products. They can use various medical instruments and test them in diverse conditions. Just as medicines, not all devices or implants are suitable for every patient. After testing or using, they can always provide feedback about the specific area of the device or medical goods, which has room for advancement. It allows the production of more efficient medical goods customized to patients' need that has increased capability and overall much better performance.

Better Quality Control and Fewer Errors

Accuracy and Quality Control are the backbones of the medical industry. There is almost no room for error during any stage of the production of medical goods. By using CNC machines, quality control measures are adopted at each step resulting in the finest possible medical supplies for the patients.

For the production of micro implantable devices, such as stents, catheters, and implants, size is the key. These devices are implanted inside the human body.

You can fit a large-size screw into the car plate or any other machine, but you cannot adjust a large or small screw into the knee implant or dynamic compression plate used to fix fractured bones. Thus, highly accurate cutting, finishing, brushing, and polishing are required to ensure the medical instrument is of the correct size.

At RapidDirect, we follow strict quality control measures for each medical device. Every medical instrument or device at our company passes through a series of quality checks. It provides the highest level of precision in terms of nanometers and micrometers without difficulty.

Cost and Time Effectiveness of the CNC Machines

Another reason making CNC machines more popular in the medical industry is the cost. CNC machine cuts the cost of producing medical supplies and instruments much lower than manual manufacturing machines. Although initially, the setup of CNC machines can cost higher, in the longer term, they are cost-effective and produce medical goods much cheaper. The reason for the cost-effectiveness are:

- Reduction in manual labor cost - CNC machines work on automation. It means they do not need any physical person to be present, at the site 24\7, like any other manual manufacturing machine.

- As discussed earlier, CNC machines make fewer errors and are more sustainable. Which means there are no energy losses. In addition, they are more power-efficient than traditional manufacturing machines. As a result, efficiency is more, and fuel bill is lesser.

- CNC machines reduce operational costs - The increased efficiency produces little waste products. They also use more raw materials reducing the cost of production of a piece of medical equipment to a much higher degree.

We have discussed other factors affecting the cost of CNC machining in another blog. You can read it here. The cost-effectiveness of the CNC machines in producing medical supplies overall causes better health care for the people. A much better quality stent is now available than ever before. And that too at a much lower price. All this is possible through CNC machining.

Manufacturing of Complex Medical Instruments

Medical Instruments are very complex structures to manufacture. They involve very fine and subtle details and need surface finishing after manufacturing. In addition, micromachining products which mean the creation of features of the medical instruments on the scale of microns, are manufactured too. At such high levels of engineering, precision, and tight tolerances becomes very important. For manufacturing such complex medical instruments, CNC machines offer much better finishing and tight tolerance and can produce these complex medical instruments.

There are a variety of complex medical instruments manufactured regularly through CNC machining. Examples include pediatric medical devices such as pediatric VADs( Ventricular Assistant Devices). These are the devices placed in the ventricles of the children having VSDs ( Ventricular Septum Defects) or some other abnormality such as heart failure. The VADs improve the heart function of the children, and they can perform their regular activities. The manufacturing of these medical devices and others, for instance, artificial heart valves and implants that involve complex configurations, are only done through CNC machining. CNC machining has 5-axis mechanic operations that can manufacture such a complicated instrument while maintaining tight tolerances and surface finishes.

Clean and Sterile Medical Instruments Production

One other reason CNC machining is becoming vital for the medical industry is its capability to produce clean and sterile medical instruments. The whole production process depends upon computer programming and automation of mechanical parts. In this way, less physical contact is involved compared to manual manufacturing methods reducing the risk of infections. As we know, most devices and medical goods produced through CNC machining are used during surgeries. Therefore, cleanliness and sterility of the instruments and devices is the most critical factor in providing the best patient care.

CNC machines have multi-axis parts, and electronic discharge machines maintain the sterility of medical devices. At BaiChuan Precision, all the CNC machines meet internationally recognized quality standards such as ISO9001 and ISO13485. These international standards ensure the cleanliness and quality of every medical instrument made through CNC machines and are the uniform industry standard.

Portability and Flexibility of CNC machines

Whenever we think about any conventional manufacturing machine, a big giant machine with heavy parts comes to mind. But that's not the situation with CNC machining. Apart from a few large ones, there are smaller machines available. These are potable means they acquire little space when we compare them to any other manufacturing machine. This feature has more value for the manufacturers as they can fit multiple CNC machines in a small space. It saves them the rent money they otherwise would spend on larger areas.

The portability of CNC machines also has some other advantages too besides cost-saving, for example:

- Accessibility of the medical instruments in the remote areas

- The production of medical supplies in case of a medical emergency. In any area for a short-term period. It does not need any large production facility.

- Potability of Digital CAD files.

In addition to portability, CNC machines are popular because of their flexibility. One CNC machine can work with different materials to produce medical goods. The parts are also flexible and work with multiple manufacturing machines reducing the need for additional ones.

User Friendliness of CNC machines

CNC machines are user-friendly. Most of them come with easy user guides and how-to-operate manuals. It means that no advanced training or course is required to operate them. The whole manufacturing process has computer-based controls with user-friendly software. The programmer or controller can program the machine according to the need.

For example, how many hours a day machine will operate or so. In addition, all the latest CNC machines come with sensors and Artificial Intelligence. They can detect promptly if any part of the machine needs repairing or cleaning. In addition, in case of any fault, the sensors will give a warning or show a check. All in all, Artificial Intelligence makes sure that CNC machines work swiftly for a longer time and make life easier for the manufacturer.

Conclusion

No doubt, CNC machining is the popular way of manufacturing medical instruments and supplies in today's world. The trend will continue to grow in the coming years, and the CNC machining technology will evolve. Because it has several advantages over manual manufacturing machines and methods, it would hold a significant market share in the medical instruments manufacturing industry.

The BaiChuan Precision is a pioneer name in CNC machining. We have experts in CNC machining always ready for your assistance. Whether you want a simple medical instrument or a complex medical machine, we can guide you through the entire process. Reach us anytime and get the best quality CNC machining Medical manufacturing service you'll ever need.