Introduction

Like many other industries, the CNC services market has seen a period of relative stability since the middle of the 20th century. However, recent developments in the Industrial Internet of Things have presented new opportunities and challenges for the market. Meanwhile, due to government travel limitations and the requirement for physical separation, attending trade exhibitions to discover new partners and secure the manufacturing of new goods has been constrained. This makes it harder for CNC machining enterprises to attract new customers on the open market.

Nevertheless, development always manages to find a way, and in the modern world the CNC machining sector is among the most forward-thinking ones in production. Here are the top trends for CNC machining for 2022 and beyond, taking into account the aforementioned factors.

The Biggest Trends in CNC Machining for 2022

The following are some trends in CNC machining to look out for in 2022 if you now use or are planning to use CNC machines:

CNC Robots

One development you should keep an eye out for in the CNC machining market is CNC robots. CNC robots are a development that shows promise since it can interact with humans and may automate risky or challenging operations in machine shops.

The usage of feedback systems and vision sensors with various forms of precision CNC machining has risen with the emergence of artificial intelligence (AI). Additionally, it has made it possible for milling machine sensors to alter their closeness or speed to the cutting surface in response to input, enabling predictive maintenance and corrections during processing. There are now additional chances for improved quality, quicker output, and longer equipment life.

Improved Accessibility To CAD/CAM Software

CAD/CAM technology is more widely available and more affordably available to businesses in the current world. User-friendliness is a top consideration for those who create these solutions. To make the technology as accessible as possible, there is also a developing community of designers and programmers.

CAD

Designers no longer need powerful computers to create a variety of parts for CNC machining due to the accessibility of cloud computing resources and the growth in computer power. These tools, when used in conjunction with various productivity-enhancing techniques, may increase the efficiency of any CNC machine and optimize profits for designers.

For companies and individual designers who previously may have required the support of larger manufacturers, the growing accessibility of CAD/CAM might open up new benefits. These modifications are also a part of a larger trend in the field of computer-aided engineering. Software for computational fluid dynamics (CFD), finite element analysis (FEA), and simulation will also become more widely available to businesses and designers throughout time.

The latest Industrial Internet of Things (IIoT) gadgets

Companies may now network CNC machines and other production equipment more easily due to new IIoT devices. New functionality for CNC machines, such remote operations monitoring, can be made possible by such devices that use the internet to receive and deliver data.

The brand-new gadgets additionally make use of IIoT sensors to monitor CNC machine operational characteristics. Making predictions about when equipment may fail or need maintenance is achievable over time by using the data that has been acquired. Companies’ maintenance schedules could be improved with the use of this strategy. Additionally, it could be useful for increasing the lifespan of CNC machines and enabling businesses to save money on maintenance.

Machining with multiple axis

Though they initially appeared in 2019, we believe 6-axis CNC machines will overtake other CNC production technologies by 2022. In the end, the manufacturing time will be quicker the more axes there are, which is consistent with the shorter product development cycles we discussed before in this article.

To construct a design in three dimensions (X, Y, and Z), most CNC machines now offer three or five axes. Five-axis CNC machines require an additional spindle to operate with an additional two axes. Rapid cut times are made possible by the six-axis CNC machines’ additional ability to rotate around the Z-axis.

Six-axis CNC machinery will prove to be suitable for high-precision manufacture of cnc machining parts like automobile components or aerospace parts that need the utmost accuracy conceivable. In 2022 and beyond, it is anticipated that an increasing number of CNC fabricators and shops will focus on this technology.

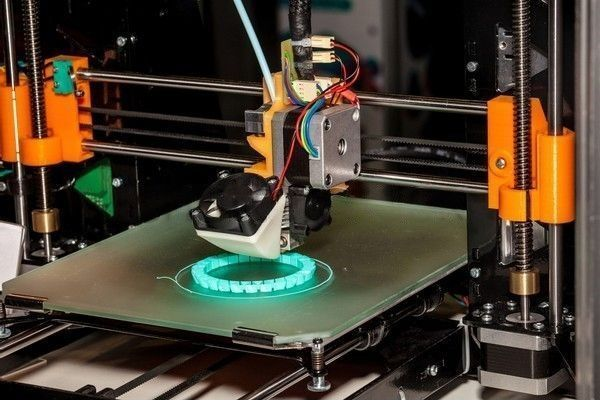

CNC machining and 3D printing combined

Unlike 3D printing, which develops three-dimensional forms layer by layer, CNC machines remove extraneous portions of a product. Although these two processes are distinct from one another, several manufacturers have included hybrid production capabilities. The technologies can be used in combination to produce a workable solution that is accurate and efficient.

One common approach is to construct the product using a CNC machine and 3D printers for rapid prototypes, with varying degrees of precision. A different option to integrate the two technologies is to start with a 3D printer to make the pieces, and then finish them with a CNC machine.

3D printing

Growth in Sustainability

Consumer demand for sustainably produced goods is rising, so CNC businesses will need to start monitoring and lowering the carbon emissions caused by their supply networks and manufacturing processes. Government restrictions, customer demand, and corporate accountability will all continue to support ongoing efforts by CNC machining services to cut carbon emissions.

All manufacturing businesses will use more available supply and production data chains starting in 2022 and beyond to better assess the carbon footprints of their products and look for new ways to produce and ship their products in a more sustainable manner.

Increased Speed and Accuracy

The effectiveness of the machining process and the caliber of the final product are strongly correlated with speed and accuracy, which are two crucial indications of CNC machines.

A bit-digit, higher-frequency processor is now used by the CNC system to increase the system’s fundamental computing performance.

In order to increase the system’s capacity for data processing—and hence the efficiency and precision of interpolation operations—ultra-large-scale integrated circuits and multiprocessor architectures are utilized concurrently.

The linear motor’s high speed and dynamic reaction properties make it a preferable choice for directly driving the linear servo feed of the machine table. Corner-cutting machining precision is enhanced by the use of feed-forward control technology, which significantly minimizes tracking hysteresis error.

Enhanced Reliability

The user’s primary concern has always been the reliability of the CNC machine. In order to minimize the number of components and increase reliability, CNC systems will include large- or ultra-large-scale dedicated and hybrid integrated circuits.

When using the modularity, standardization, and generalization of the hardware structure of the machine body and series, it is possible to better the hardware production batch while also organizing production and quality control. This is accomplished by using the hardware function software to adapt to the requirements of various control functions.

Through automated start-up diagnostics, online diagnostics, offline diagnostics, and other diagnostic processes, it also enables troubleshooting and alerting of the system’s hardware, software, and numerous external devices.

Intensifying Manufacturing-as-a-Service (MaaS)

Manufacturing as a service (MaaS) has just recently entered the CNC machining industry, but as time moves forward in 2022, we may anticipate it to become more widely accepted. Manufacturing as a service, relies on networked resources to complete manufacturing operations since CNC machines and equipment are all housed in one central location. The service’s customers are also responsible for covering the costs of operation, maintenance, and repairs.

MaaS can further provide businesses increased flexibility, greater productivity, agility, and cost savings through lower personnel costs. As a result, as long as the effects of the pandemic linger, it is reasonable to predict that businesses with limited funding would at least consider the option of signing up for a MaaS service driven by CNC.

Additional Ways to Learn CNC Machining

Offering a solution for the lack of personnel competent to run CNC machines while keeping on present employees is one trend for 2022. Due to the epidemic, it became necessary to combine online and hands-on learning to allow individuals to further their education from home. Siemens saw this chance and created a course aimed at those who are considering a career in CNC machining. Participants in their program, which also offers on-site training, must be able to access their educational facilities. Users may access online training resources and sessions anytime they want as well.

Conclusion

Despite the Covid-19 pandemic’s unforeseen business disruptions over the past two and a half years, the CNC machining sector will remain at the forefront of global production. In order for businesses to be more flexible and adaptive in these uncertain times, they will need to discover methods to accelerate the development of their new product ideas and find environmentally friendly ways to manufacture their products.

Furthermore, in order to reduce the expenses associated with the maintenance and operation of the machines, CNC manufacturers will start integrating six-axis CNC machining into their facilities or signing up for the expanding MaaS CNC services that have developed in recent years.

At CNC Milling China, Kunshan Baichuan have made the greatest equipment investments to meet all of your CNC machining demands and stay current with industry trends. Allow us to assist you in meeting the needs of your sector by offering individualized cnc services and producing effective and high-quality solutions. Write a review below or “Contact us here with any additional inquiries”