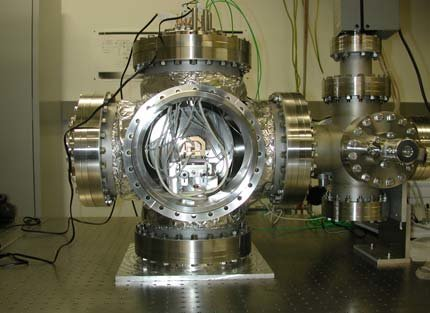

Vacuum chambers are crucial equipment utilized in numerous scientific, commercial, and technical applications. These chambers establish and maintain a regulated environment free of air and other impurities, allowing scientists and engineers to examine and work with various materials in a vacuum. It is essential to choose materials carefully in order to ensure compatibility, durability, and safety to get the appropriate vacuum levels.

These components are essential for preserving the chamber's integrity, preventing leaks, withstanding adverse weather, and reducing contamination. To develop and build efficient hoover systems, it is crucial to comprehend the traits and qualities of these materials. The various types of materials frequently utilized in vacuum chambers will be examined in this article. So, Let’s dive deep into it.

Importance of Material Selection for Vacuum Chambers

Vacuum chamber design and performance heavily depend on the material choice. Industrial applications for vacuum chambers include semiconductor production, particle accelerators, aerospace, and high-energy physics investigations. The following factors make the choice of vacuum chamber materials crucial:

Vacuum Integrity:

The fundamental purpose of a vacuum chamber is to sustain a high vacuum for a lengthy period of time. Low outgassing rates, little gas permeability, and low vapor pressure should all be characteristics of the material employed. Low outgassing materials reduce the number of gas molecules released from the chamber walls, which may pollute the vacuum and impair its ability to function. Gases cannot diffuse through the chamber walls and cause vacuum leaks, which is prevented by a lack of permeability.

Structure integrity:

Vacuum chambers are used under varied mechanical and thermal strains, which might compromise their structural integrity. The material must be strong, rigid, and deformation-resistant under vacuum conditions. Additionally, it needs to be capable of withstanding temperature variations and maintaining dimensional stability without endangering the integrity of the Hoover.

Compatibility:

The substance must be able to coexist peacefully with the substances or procedures being carried out inside the vacuum chamber. The chamber might be exposed to unfavorable environments, for instance, corrosive gases, chemicals, or extreme temperatures. The material should be able to tolerate the process conditions without deteriorating or being contaminated, be corrosion-resistant, and be chemically inert. To avoid material deterioration and cross-contamination, compatibility is crucial.

Thermal Conductivity:

Controlling heat in vacuum chambers is essential, particularly when working with high-power equipment or procedures. To enable effective cooling or heating of the chamber, the material must have the right thermal conductivity qualities. A chamber's heat is dissipated and its temperature distribution is ensured to be uniform due to good thermal conductivity.

Electrical Conductivity:

The material's electrical conductivity must be taken into account in some applications, for instance, plasma research or particle accelerators. Conducting components can help reduce electromagnetic interference (EMI) and give the chamber's electrical systems or experimentation a controlled environment.

Common Materials Used in Vacuum Chambers

Usually, materials that can tolerate high vacuum and provide reliable sealing are used to build these chambers. In vacuum chambers, the following materials are frequently used:

Stainless steel:

Due to its outstanding mechanical strength, corrosion resistance, and high-temperature tolerance, stainless steel is a preferred material for vacuum chamber construction. It is frequently applied in both academic and professional contexts.

Aluminum:

Aluminum is inexpensive, lightweight, and has strong thermal conductivity. It is frequently employed in industries where weight reduction is crucial, such as portable vacuum systems and aerospace. However, compared to stainless steel, aluminum is less strong.

Aluminum Vacuum Chamber

Glass:

In vacuum chamber applications where visibility or transparency is desirable, specific types of glass, such as borosilicate glass (ex. Pyrex), can be employed. Glass chambers can be used in lower to medium-vacuum environments, but they might not be suited in greater or ultra-high-vacuum settings.

Titanium:

Titanium is renowned for its superior strength, low outgassing, and corrosion resistance. It is frequently employed in applications requiring high vacuum or ultra-high vacuum, like synchrotrons or particle accelerators.

Copper:

Copper has strong thermal conductivity, making it a popular material for vacuum chamber parts that need to transmit heat effectively. When high electrical conductivity is required, such as in cryogenic applications, it is especially helpful.

Teflon:

Teflon (Polytetrafluoroethylene, or PTFE) is a chemically inert and non-reactive substance that is frequently employed for gaskets, O-rings, and other sealing components in vacuum chambers. It has good sealing abilities and is able to endure a wide temperature range.

Viton:

Fluoroelastomer Viton is well-known for its outstanding resistance to extreme heat, chemicals, and vacuum conditions. It is commonly employed in vacuum chamber sealing applications.

It's crucial to keep in mind that the material selection for a vacuum chamber is determined by the particular needs of the user, which include the vacuum level, temperature, chemical reliability, and the existence of any harmful compounds. A dependable and leak-free vacuum environment is also crucially maintained by chamber design and construction methods.

Selected Best Materials:

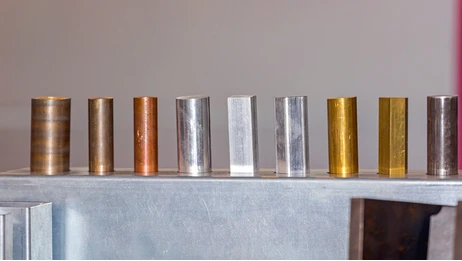

Different Metals Photo from shutterstock

Stainless steel:

The most common type of material for vacuum components is stainless steel. The mechanical strength (yield strength of 200 GPa) is adequate for building specialized Hoover systems. It's simple to weld. It is a common material that is readily available on the market and frequently utilized in construction projects. The flanges are shielded from dents and leaks by their high hardness (190 HB). The rates of outgassing are minimal. Stainless steel can be burned (at 900°C) to eliminate the H2 from the main body of the material and baked in place (at 150 to 350°C) to remove the water from the surface. Austenitic steels can be utilized in magnets because they are non-magnetic.

It's crucial to take into account details like the intended vacuum level, the operating temperature range, and compatibility with any process gases or materials used inside the chamber. The particular mechanical requirements of the application when choosing a stainless steel grade for a vacuum chamber.

Cold-rolled plates are typically used to make tubes and containers. The recrystallization temperature for stainless steel is around 400°C, which is referred to as being "cold." The surface of cold-rolled plates is smoother.

Aluminum:

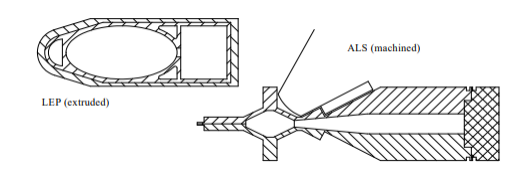

Many electron synchrotrons (PETRA, TRISTIAN, LEP, LEAR, ALS, SRRC, APS, LEP,

Pohang, Spring8) have been made of aluminum. Aluminium has been used primarily because long beam tubes, such as the antechambers for distributed pumps and cooling ducts, can be made at a reasonable cost through extrusion.

Furthermore, solid blocks can be used to machine intricate chambers. Figure [1] depicts the cross-section of the extruded aluminum LEP vacuum chamber [2] and the thick plate-machined ALS vacuum chamber at a quadrupole. Aluminum's excellent thermal conductivity makes it simple to distribute and cool the heat load.

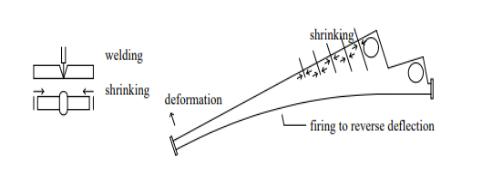

The chamber of the ANKA prototype has a distorted weld

Thus, assuming the power density of the synchrotron radiation is not too high, it can be directly absorbed on the chamber wall. Additionally, by employing pressurized water, the cooling ducts can be easily employed for low-temperature baking (150 °C). The industry currently offers standard parts (tubes, fittings, T, and cross pieces) as shown in the figure below. It also offers the advantages of being fully non-magnetic, having a low activation cross-section, and having quick radioactive decay.

Aluminum Vacuum Chamber of LEP and ALS

Copper:

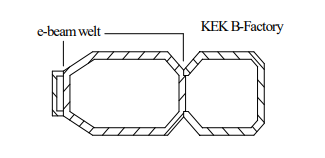

At HERA (DESY) and the KEK B plants copper is used for the hoover system. It serves as a synchrotron radiation absorber in almost all accelerators. Fig. 13 depicts the profile of the KEK B factory vacuum chamber. OFHC (Oxygen-free higher conductivity) Copper is typically utilized. To increase stiffness and prevent softening during brazing, copper-tin (3%) and bronze were utilized at HERA. Large beam tubes can be made by extrusion, although only with one duct when compared to aluminum. As a result, the cooling duct and the antechamber for distributed pumps must be extruded individually and joined to the beam chamber using an e-beam. As a result, the production process is more expensive and complicated.

Standard seals are made of copper. OFHC copper is primarily used. A copper-silver alloy (0.1%) with a greater recrystallization temperature should be used for baking at temperatures higher than 200°C in order to prevent copper from flowing. A silver coating can also stop the gasket from sticking.

Most SR sources use copper blocks composed of OFHC with brazed water pipes or drilled cooling ducts as their primary absorbers. Because an absorber's temperature is not constant, thermal stress develops, which causes cracks and failure. GLIDCOP, a copper aluminum oxide Cu Al 2O3 (0.3) alloy that allows for higher stress, is utilized to prevent failures when the heat load is too high for OFHC copper. But brazing GLIDCOP to copper is difficult and fairly expensive.

Carbon-fiber composite material:

For the Super Proton Synchrotron (SPS) collision area at CERN, carbon-fiber composite vacuum chambers have been created. The vacuum tube material needs to be extremely transparent for the collision products travelling to the detector in this region (length 13 m).

Thus, a material with a relatively small Z and high strength should be utilized. The ideal material would have been beryllium, but it is fairly expensive, especially for a 13-m beam duct. A carbon-fiber tube with an inner layer of aluminum (40 m) was designed as a comparable substitute, having a similar transparency to beryllium but only costing around 15% as much.

To achieve a low outgassing rate and electromagnetically shelter the detectors from the high-frequency field of the stored beam, the aluminium layer was required as a barrier for gas diffusion through the composite. A pressure difference of 1.5 bar was intended for the chambers. Before collapsing, one chamber was tested to 1.95 bar.

He and water pressure had a penetration rate (10-8 mbar l/(s cm 2 )) in chambers without an aluminium lining. He entered chambers with an aluminum liner at a rate of 10-9 mbar l/(s cm 2). After two 24-hour bakes at 120°C, an outgassing rate of 10–12 mbar l/(s cm 2 ) could be attained.

Ceramics:

In rapidly changing magnetic fields (kickers), where conducting materials produce unacceptably high eddy currents, ceramics (mainly aluminum oxide, which can be made without porosity) are employed as insulators (feedthroughs, breaks), vacuum chambers, and kickers. Ceramics is superior to glass in terms of mechanical strength.

Additionally, when compared to tensile strength, compressive strength is ten times greater.

Therefore, only compressive stress should be considered while designing ceramic systems.

Clay (water-soluble oxide powder) is molded into tiny particles, pressed into molds or extruded, and then allowed to dry to create ceramics. Machine cutting is possible after drying. The components are then sintered at 2000°C. The material shrinks up to 20% in length during this procedure.

Brazing is used to join the majority of ceramic parts to metal (flanges). Prior to sintering, a MoMn or titanium hydride coating metalizes the ceramic surface intended for brazing in the typical brazing method. The ceramic can then be brazed to metals, ideally those with an expansion coefficient similar to that of the ceramic (nickel-iron, nickel cobalt iron, titanium, molybdenum). As filler, copper, and silver eutectic is utilized. The stainless steel flanges and the interface metal can then be joined using an electron beam welder.

Magnetic Materials:

In an ultra-high vacuum (UHV), magnetic materials (ferrites, high-iron, and permanent magnets) are often not employed because they all exhibit a significantly higher outgassing rate than stainless steel. They may be porous or susceptible to corrosion as a result of the manufacturing process. However, by putting the magnets within the hoover, more strength is gained since the performance of insertion devices improves with a reduced gap. This is frequently done in conjunction with the setting up of a high pumping speed to offset the increased gas load.

For the pulsed magnetic fields present in kickers, for instance, ferrites are used. Their maximal field is 0.3 T and relative permeability is 1000 up to 10 MHz. The main ingredients are (NiZn) Fe2O4. With the exception of the lower sintering temperature of 1200°C, the manufacturing method is the same as for ceramics.

Prior to the transistor taking the role of the electronic tube, glass served as the industry standard for vacuum materials. Windows and a few other specialized electronic tubes (thyratrons) are the principal uses for it today. Whether they are pure (quartz) or borosilicate, silicon-oxide glasses are useful.

Quartz is resistant to thermal shock and has a very low thermal expansion coefficient, a wide operating temperature range, and a high working temperature range. The rate of surface desorption is minimal, although helium and hydrogen can pass through thin glass tubes, particularly quartz and to a lesser extent pyrex.

Coatings and Surface Treatments for Vacuum Chambers

In order for vacuum chambers to function properly and perform as intended, coatings and surface treatments are essential. They contribute to increased durability, decreased contamination, improved thermal characteristics, and improved vacuum integrity. Following are some typical surface treatments and coatings applied to vacuum chambers:

Electroless Nickle Plating:

When coating the surfaces of vacuum chambers, electroless nickel plating is a common choice. It offers superb wear resistance, corrosion resistance, and a uniformly smooth coating. This coating reduces contamination in the vacuum environment and aids in the prevention of outgassing.

Anodizing:

Anodizing is an electrochemical procedure that coats the surface of metals like aluminum with a protective oxide coating. It increases surface hardness, decreases outgassing, and improves corrosion resistance. To reduce surface contamination, vacuum chambers frequently employ anodized coatings.

Physical Vapour Deposition (PVD):

PVD is a thin-film deposition process in which solid materials are vaporized and then deposited onto the vessel's wall. PVD coatings provide superior wear resistance, low friction, and increased hardness. Examples include titanium nitride (TiN) and chromium nitride (CrN). These coatings are frequently applied where high-performance surfaces are necessary or where there is a high wear rate.

Plasma Nitriding:

Metals' hardness and wear resistance can be increased using the surface treatment method known as plasma nitriding. A hard nitride layer is created by revealing the vessel's surface to a nitrogen plasma, which diffuses nitrogen into the material. The resistance to galling, fretting, and corrosion is increased through plasma nitriding, making it suited for vacuum chambers that are exposed to mechanical stress.

Chemical Vapour Deposition (CVD):

During CVD, gas-phase chemical reactions result in the formation of a thin film on a substrate. Diamond-like carbon (DLC) and silicon carbide (SiC) are two CVD coatings that provide superior hardness, reduced friction, and chemical resistance. When little outgassing is crucial or when high temperatures are involved, these coatings are frequently utilized.

Passivation:

To get rid of impurities, pollutants, and free iron, the chamber surface is treated with a chemical solution. This procedure increases corrosion resistance and contributes to keeping the hoover environment clean. Surfaces made of stainless steel that is used in vacuum chambers frequently undergo passivation.

The selection of a coating or surface treatment must take into account the particular needs of the vacuum chamber, including the operating circumstances, the materials employed, and the intended performance characteristics. Determine the best option for your application by speaking with specialists or manufacturers who focus on vacuum chamber coatings.

Material Considerations for Specific Vacuum Applications

To ensure system compatibility, performance, and safety, numerous considerations must be made while choosing materials for certain hoover applications. For various components frequently used in vacuum applications, the following are some important material considerations:

Vacancy Chambers

Material: The vacuum chamber required material with good vacuum compatibility, high strength, and corrosion resistance, thus, stainless steel (usually 300 series) is often utilized. For particular purposes, other materials like glass, titanium, or aluminum may be appropriate. To reduce outgassing and ensure better hoover performance, smooth and polished surfaces are ideal.

Seals and O-Rings

Material: Choose fluorocarbons (like Viton® or Kalrez®), perfluoro elastomers (like Chemraz®), or metal seals like copper or aluminum over materials with high outgassing rates and limited chemical compatibility with the process environment. Make sure the material has a low compression set in order to sustain a strong seal over time.

Flanges and gaskets:

Material: Materials that can survive high vacuum levels, like stainless steel, copper, or aluminum, should be used to make gaskets and flanges. The option to choose will rely on the application's particular needs, such as temperature, pressure, and chemical compatibility.

Pumps for Hoover:

Materials for Pump Construction: Depending on the kind of pump (rotary vane, turbo, cryogenic, etc.), different materials are used to construct different pump components. Stainless steel, aluminum alloys, and different tailored polymers are common materials.

Materials for Sealing and Lubrication: Consider using perfluoropolyether (PFPE) oils and greases as sealants and lubricants because they are suitable for hoover environments.

Feedthroughs for Hoover and electrical connectors

Materials: Glass-to-metal seals, ceramics, and stainless steel are frequently used for feedthroughs and connectors. The chosen material should be suitable for the working temperature and electrical requirements, have acceptable electrical insulating capabilities, and be able to tolerate vacuum conditions.

Window Components:

Material: Window materials might vary depending on the wavelength range and particular requirements. Fused silica, sapphire, calcium fluoride, and germanium are a few popular options. Each material's gearbox characteristics vary, and some materials might be better suited for particular applications.

Surface treatments/ Coatings:

Materials: For reflectivity in optical applications, coatings made of gold, silver, or aluminum are frequently utilized. Passivation and electropolishing are two surface treatments that can lessen outgassing and enhance corrosion resistance.

In order to verify that the materials you choose are compatible with the precise vacuum levels, temperatures, and chemical conditions of your application, it is vital to speak with specialists or material suppliers who specialize in vacuum technology.

Challenges and Limitations in Material Selection for Vacuum Chambers

There are many difficulties and restrictions to take into account while choosing materials for vacuum chambers. The following are some important things to bear in mind:

Outgassing:

To reduce the leakage of gases and vapors from the chamber walls, vacuum chambers require materials with low outgassing rates. In applications that call for ultra-high vacuum (UHV) conditions, outgassing can result in contamination of the vacuum environment. In order to avoid surface contamination, materials with low vapor pressures are preferable.

Permeability:

Another crucial factor to take into account is the material's permeability to gases. The high gas permeability of some materials, such as plastics or elastomers, may cause the passage of atmospheric gases into the vessel or the escape of gases from within the vessel. Since metallic materials have a reduced gas permeability, they are frequently chosen.

Resistance to high temperatures:

Vacuum chambers might be exposed to high temperatures, particularly in industries like thermal processing or plasma studies. To retain their structural integrity and function at high temperatures, the materials chosen for these chambers should be sufficiently temperature resistant. In these circumstances, high-temperature alloys or ceramics are frequently employed.

Vacuum Compatibility:

Materials should not deteriorate, emit gases, or otherwise contaminate the vacuum when used in vacuum chambers. Compatibility is influenced by variables like the vacuum level (from rough vacuum to UHV), the specific gases present, and the existence of reactive species. For various vacuum levels, different materials could be required, and in some cases, surface modifications or coatings might be used to increase compatibility.

Limitations due to Size and Fabrication:

Fabrication methods and chamber size constraints may also have an impact on the materials available. Some materials could be challenging to machine or weld, particularly in complex geometries or large-scale chambers.

Future Trends in Vacuum Chamber Material Selection and Design.

Innovations in material selection and design are essential for achieving higher vacuum levels, lowering contamination, and enhancing overall performance in the field of vacuum technology. The following are some predicted trends in vacuum chamber choice of materials and design:

High-Temperature Materials:

Vacuum chambers must function at high temperatures in many applications. The creation and application of high-temperature materials that can endure extremely high or low temperatures while preserving structural integrity is a trend for the future. In these situations, the use of advanced ceramics, refractory metals, and metal alloys with high melting points may increase.

Surface Coatings:

Surface coatings and treatments have a big impact on how well vacuum chambers work. New coatings will probably be created in the future to enhance qualities including outgassing rates, thermal conductivity, radiation resistance, and contaminant reduction. To improve chamber performance, thin films, nanostructured coatings, and specific surface chemistries will be investigated.

Sustainable Materials and Manufacturing:

Future designs of vacuum chambers may give preference to the use of ecologically friendly materials and production techniques as sustainability is becoming a more important notion. Vacuum technology's environmental impact will be mitigated through the use of recyclable materials, biodegradable polymers, and energy-efficient manufacturing methods.

Computational Modelling and Simulation:

Vacuum chamber design will continue to be significantly influenced by sophisticated computational modelling and simulation technologies. These technologies give engineers the ability to estimate performance, simulate vacuum conditions, optimize chamber shape, and spot potential problems before the chamber is built. This pattern will quicken the designing procedure and result in hoover systems that are more dependable and efficient.

The Conclusion:

In a wide range of scientific, industrial, and technical endeavors, vacuum chambers are crucial tools. The choice of materials for vacuum chamber construction depends on a number of variables, including the desired vacuum level, pressure differentials, required temperatures, and the particular application at hand.

Commonly utilized materials include stainless steel, aluminum, glass, titanium, and ceramics; each has special qualities that make it appropriate for particular vacuum chamber applications. The selection of material is essential for achieving optimal performance and maintaining the desired vacuum conditions inside the chamber, whether it be due to the durability of stainless steel, the light weight of aluminum, the transparency of glass, the toughness of titanium, or the unique properties of ceramics.

This blog was helpful for you? Do you have anything to share on this topic? Let us know by commenting below.