Saltwater environments mercilessly attack metal components, threatening structural integrity and safety. Sailboat owners face constant battles against corrosion that can lead to costly repairs and dangerous failures.

The best marine-grade aluminum alloys for sailboat components are 5000-series alloys, particularly 5083 and 5086, which contain higher magnesium content (4-5%) that forms a stable oxide layer providing superior saltwater corrosion resistance. For above-water applications, 6061-T6 offers an excellent strength-to-weight ratio with good machinability.

Marine aluminum alloys showing different corrosion resistance properties

As a CNC machining specialist for marine applications, I've seen firsthand how choosing the right aluminum alloy can mean the difference between components lasting decades versus failing prematurely. Let's dive into the specific alloys that stand up best to marine environments and why their properties matter for your sailboat components.

How Does Saltwater Environment Impact Aluminum Corrosion Behavior?

The combination of salt, moisture, and oxygen creates a perfect storm for metal degradation. Without proper material selection, even premium sailboat components can deteriorate rapidly, leaving you stranded or facing dangerous equipment failures.

Saltwater creates a highly conductive electrolyte that accelerates galvanic corrosion in aluminum. The chloride ions in seawater penetrate the natural oxide layer of aluminum, causing pitting corrosion that progresses deeper into the metal. This process is further accelerated by temperature fluctuations, biological growth, and mechanical stresses typical in marine environments.

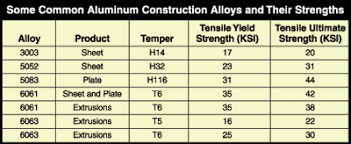

Close-up of pitting corrosion on aluminum exposed to saltwater

The marine environment presents multiple corrosion mechanisms that affect aluminum differently than land-based applications. Pitting corrosion is particularly problematic because it creates localized deep penetration that can cause structural failure with little visible warning. I've examined aluminum components that looked relatively intact from the outside but were compromised by extensive internal corrosion.

The unique challenges of saltwater exposure require specific alloy properties to resist degradation. Chloride ions from seawater are particularly aggressive toward aluminum, breaking down the passive oxide layer that normally protects the metal. Additionally, the galvanic corrosion risk increases dramatically when aluminum contacts dissimilar metals in the presence of saltwater.

Temperature variations and constant wetness/drying cycles further stress materials. In my experience machining marine components, I've found that alloys with higher magnesium content form more stable oxide layers that better resist these chloride attacks. This is why we typically recommend different alloy families for parts that will be continuously submerged versus those exposed to splash or atmospheric salt conditions.

| Corrosion Type | Description | Prevention Strategy |

|---|---|---|

| Pitting | Localized deep penetration | Higher Mg content alloys, proper anodizing |

| Galvanic | Dissimilar metal contact | Isolation, sacrificial anodes, compatible alloys |

| Crevice | Occurs in tight spaces | Design optimization, sealants, avoiding water traps |

| Stress Corrosion Cracking | Combined stress and corrosion | Proper heat treatment, stress relief |

Why Are 5000-Series Alloys Preferred for Marine Hull Components?

Boat hulls face constant exposure to corrosive elements, creating an unforgiving environment where material failures can be catastrophic. Choosing inferior alloys leads to costly repairs and potential safety hazards that no boat owner can afford.

The 5000-series aluminum alloys, especially 5083 and 5086, are preferred for marine hull components because they contain 4-5% magnesium, which forms a highly corrosion-resistant oxide layer. These alloys maintain strength and toughness after welding without heat treatment, making them ideal for hull construction where structural integrity is paramount.

CNC-machined 5083 aluminum hull components

When machining hull components for sailboats, I've consistently seen superior performance from the 5000-series alloys in saltwater applications. The science behind their effectiveness is fascinating – their higher magnesium content creates a more stable protective oxide layer that resists breakdown from chloride ions. This natural defense mechanism is why 5083 and 5086 have become industry standards for hull plates and underwater components.

The work-hardening characteristics of these alloys provide another advantage. Unlike heat-treatable alloys that can lose strength in weld zones, 5000-series alloys maintain excellent mechanical properties throughout the structure. This is critical for hull integrity, where welded joints must withstand significant stress. Additionally, these alloys demonstrate superior fatigue resistance under cyclical loading conditions typical in marine environments.

When considering cost versus performance, 5083 offers the best value for most hull applications. While slightly more expensive than some alternatives, its extended service life and reduced maintenance requirements deliver lower total ownership costs. In my factory, we've machined thousands of 5083 components that continue to perform flawlessly after years in harsh marine environments.

| Alloy | Mg Content | Yield Strength (MPa) | Corrosion Resistance | Best Applications |

|---|---|---|---|---|

| 5083 | 4.0-4.9% | 228 | Excellent | Hull plating, frames, stringers |

| 5086 | 3.5-4.5% | 207 | Excellent | Hull components, brackets |

| 5052 | 2.2-2.8% | 193 | Very Good | Interior components, tanks |

| 5456 | 4.7-5.5% | 230 | Excellent | High-strength hull structures |

When Should You Choose 6061 vs. 5083 for Above-Waterline Applications?

Making the wrong alloy choice for deck hardware and rigging components can lead to premature failures, safety risks, and unnecessary maintenance costs. The decision between strength and corrosion resistance becomes critical for performance.

For above-waterline applications, choose 6061-T6 when higher strength, better machinability, and aesthetic finish are priorities, such as for deck hardware, rails, and structural supports. Select 5083 when maximum corrosion resistance is needed for components exposed to frequent saltwater spray or in humid marine atmospheres.

Side-by-side comparison of 6061 and 5083 aluminum parts

The decision between 6061 and 5083 for above-waterline components involves balancing several factors. From my experience machining thousands of marine components, I've developed a practical framework for this selection process. Components that need precise machining, threaded features, and higher strength often benefit from 6061-T6, while those with constant saltwater exposure perform better in 5083.

The machinability difference is substantial – 6061-T6 cuts more cleanly, holds tighter tolerances, and produces better thread quality. This makes it ideal for components with complex geometries or precision requirements. We can achieve faster production rates with 6061, which often translates to cost savings for customers. However, this advantage must be weighed against the superior corrosion resistance of 5083 in harsh environments.

Heat treatability represents another key difference. The T6 temper of 6061 provides approximately 35% higher yield strength than 5083, making it better suited for load-bearing components where weight is a concern. However, this strength advantage diminishes in welded assemblies, as the heat-affected zone loses its temper. When designing welded structures, this strength reduction must be factored into material selection.

Anodizing performance also differs between these alloys. 6061 responds better to anodizing treatments, producing more consistent and attractive finishes. For visible components where aesthetics matter, this can be a deciding factor. In my experience, cabin hardware, helm components, and electronic mounting brackets often use 6061-T6 for this reason, combined with appropriate protective treatments.

| Factor | 6061-T6 | 5083-H321 | Selection Consideration |

|---|---|---|---|

| Yield Strength | 276 MPa | 228 MPa | Choose 6061 for higher structural loads |

| Machinability | Excellent | Good | 6061 for complex, precision components |

| Corrosion Resistance | Good | Excellent | 5083 for frequent saltwater exposure |

| Weldability | Good (strength loss) | Excellent (no strength loss) | 5083 for welded structures |

| Cost | Lower | Higher | 6061 for budget-sensitive projects |

What Role Does Magnesium Content Play in Marine Aluminum Durability?

Without understanding the critical role of magnesium in aluminum alloys, boat owners risk selecting inferior materials that quickly succumb to the harsh marine environment, leading to costly failures and potential safety issues.

Magnesium content significantly enhances marine aluminum durability by forming a more stable protective oxide layer that resists chloride ion attack. Alloys with 4-5% magnesium (like 5083) demonstrate superior corrosion resistance in saltwater, while also providing improved strength without heat treatment and better resistance to stress corrosion cracking.

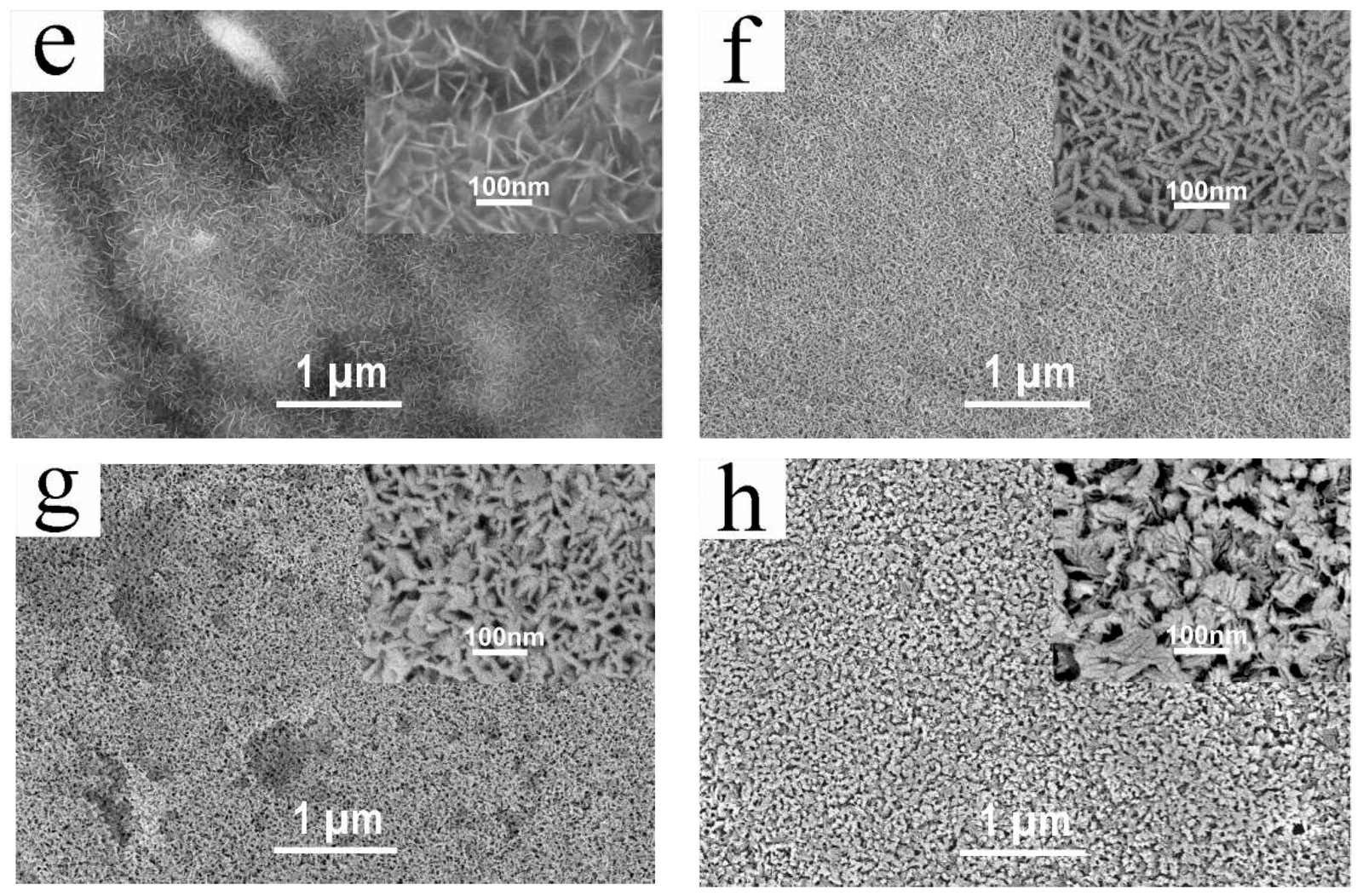

Microscopic view of oxide layer formation on high-magnesium aluminum

Through years of CNC machining marine components, I've observed a direct correlation between magnesium content and long-term performance in saltwater environments. The science behind this relationship is fascinating. Magnesium in aluminum creates a more robust oxide layer that better resists the aggressive chloride ions found in seawater. This protective mechanism makes higher-magnesium alloys the preferred choice for components with direct saltwater exposure.

However, there's a balancing point. While increasing magnesium improves corrosion resistance, it affects other properties. Alloys with very high magnesium content (above 5.5%) become more difficult to machine and can experience issues with stress corrosion cracking under certain conditions. This is why the 4-5% magnesium content in 5083 represents an optimal balance for marine applications.

The interaction between magnesium content and other elements also affects performance. For instance, controlling the silicon-to-magnesium ratio in 6000-series alloys is crucial for achieving the right balance of strength and corrosion resistance. In our manufacturing process, we carefully select alloys based on the specific environmental conditions and stress requirements of each component.

Practical experience has shown that components made from higher-magnesium 5083 alloy consistently outlast those made from lower-magnesium alternatives in harsh marine environments. For underwater hardware and hull fittings, this durability difference can mean years of additional service life. The initial cost premium for these alloys is minimal compared to the extended lifespan and reduced maintenance requirements.

| Alloy Series | Typical Mg Content | Corrosion Resistance | Best Marine Uses |

|---|---|---|---|

| 5000-series | 3.5-5.5% | Excellent | Hull plates, underwater hardware |

| 6000-series | 0.8-1.2% | Good | Above-waterline components |

| 7000-series | 2.1-2.9% | Fair | Limited marine use |

| 3000-series | 0.05-1.3% | Good | Indoor marine components |

How Can Surface Treatments Enhance the Performance of Marine Aluminum Parts?

Even the best aluminum alloys will eventually fail without proper protection. Untreated components face accelerated corrosion that compromises safety and leads to expensive replacements, but the right treatments can dramatically extend service life.

Surface treatments significantly enhance marine aluminum performance through multiple mechanisms. Anodizing creates a hard, protective oxide layer that resists corrosion and provides an excellent base for primers and paints. Chromate conversion coatings offer additional protection, while proper sealants prevent water intrusion in crevices and fastener areas.

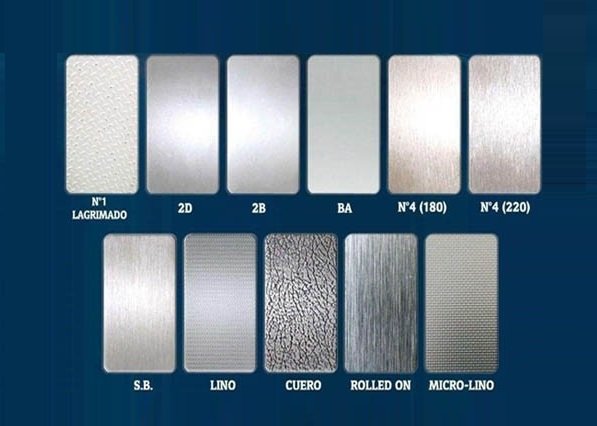

Various surface treatments on aluminum marine parts

Surface treatments represent a critical final step in producing durable aluminum marine components. In our CNC machining facility, we've developed specialized post-machining processes that significantly extend component life. The most effective approach combines multiple treatment strategies tailored to the specific exposure conditions each part will face.

Anodizing stands as the foundation of most protection systems. This electrochemical process artificially thickens the natural oxide layer on aluminum, creating a harder, more corrosion-resistant surface. For marine components, we typically specify Type II (sulfuric acid) anodizing with a minimum thickness of 0.8-1.0 mil (20-25 microns). This provides excellent protection while maintaining dimensional tolerance for precision parts. For components with severe exposure, hard anodizing (Type III) offers even greater protection, though with some color limitations.

Sealing the anodized layer is equally important. Hot water sealing remains effective for many applications, but nickel acetate or dichromate sealing provides superior corrosion protection for critical marine components. We've found that this additional step significantly extends service life in splash zone applications where components experience frequent wetting and drying cycles.

For components where anodizing isn't practical (such as welded assemblies), conversion coatings offer an alternative protection strategy. Chromate conversion coatings provide excellent corrosion resistance and create an ideal surface for paint adhesion. While environmental regulations have limited some traditional chromate processes, newer trivalent chromium and non-chromium alternatives have improved significantly in recent years.

Paint systems specifically designed for marine aluminum offer another protection layer. Two-part epoxy primers followed by polyurethane topcoats provide excellent durability in marine environments. The key is proper surface preparation – any contamination or improper pretreatment dramatically reduces coating effectiveness. In our experience, combining mechanical surface preparation (like abrasive blasting) with chemical cleaning yields the best paint adhesion results.

| Surface Treatment | Protection Level | Best Applications | Limitations |

|---|---|---|---|

| Type II Anodizing | Good | General marine components | Cannot be applied after welding |

| Hard Anodizing (Type III) | Excellent | High-wear components, underwater hardware | More expensive, limited color options |

| Chromate Conversion | Good | Base for painting, welded assemblies | Environmental restrictions |

| Epoxy/Polyurethane Paint | Very Good | External components, aesthetic surfaces | Requires maintenance, can chip |

| PTFE/Ceramic Coatings | Excellent | Moving parts, high-wear areas | Specialized application, higher cost |

Conclusion

The optimal marine aluminum alloy choice depends on specific exposure conditions and performance requirements. 5000-series alloys excel underwater, while 6061-T6 offers better machinability for above-waterline components. Proper surface treatments are essential for maximizing component lifespan in harsh saltwater environments.