In CNC machining, solution treatment can be a game-changer. It impacts material properties profoundly, unlocking potential performance improvements in metal parts.

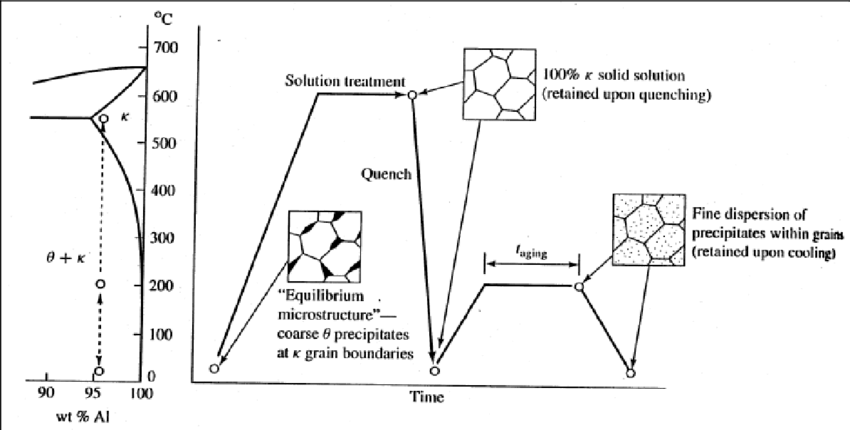

Solution treatment is a heat treatment process that dissolves precipitates to improve the uniformity and mechanical properties of machined components. It enhances strength, hardness, and durability, essential for high-performance applications.

Solution treatment isn’t just a post-process step. It’s crucial for achieving the mechanical characteristics needed in intense and demanding environments like aerospace and automotive industries.

How Does Solution Treatment Improve Material Properties of Machined Parts?

If performance is paramount, solution treatment can transform machined parts. It optimizes structural integrity, essential for durability and resilience.

By dissolving precipitates, the process increases tensile strength and resistance to stress corrosion cracking, making machined components safer and more reliable under load.

Understanding how solution treatment enhances properties helps in applying it effectively. It's about using precise heat cycles to achieve a uniform microstructure. Temperature precision and controlled cooling are vital. Solution treatment readies the metal’s crystal lattice for future hardening processes, ensuring longevity in service.

Which Alloys Benefit Most from Solution Treatment After CNC Machining?

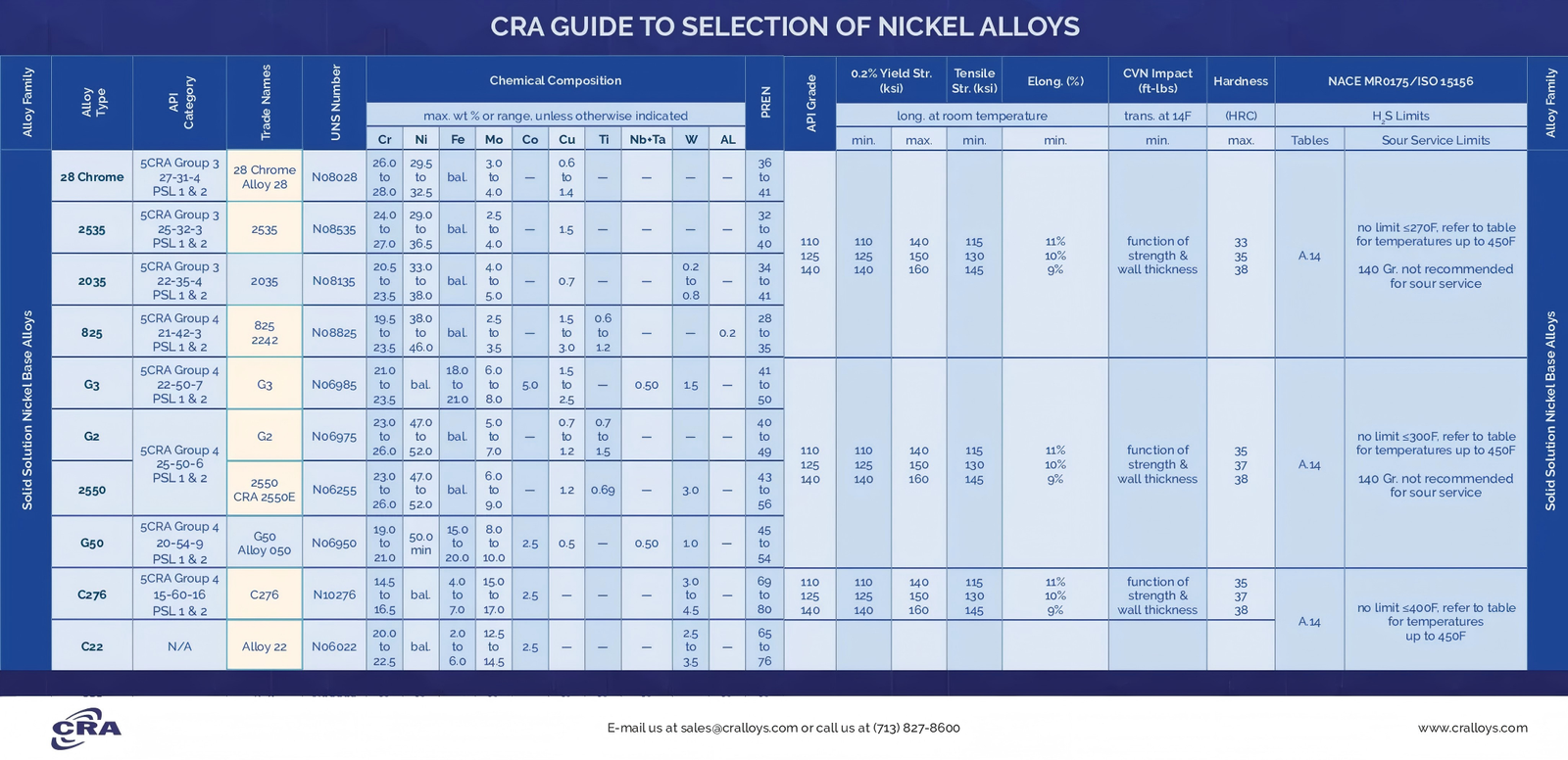

Every alloy has unique characteristics. Some respond better to solution treatment, offering significant property enhancements.

Aluminum and magnesium alloys typically show substantial improvements. Their increased ductility and strength post-treatment make them favorites in aircraft and automotive parts.

The aluminum series, particularly 2xxx, 6xxx, and 7xxx, benefit from solution treatment due to improved mechanical properties like strength and fatigue resistance. Magnesium alloys gain enhanced ductility and stability. Understanding which alloys thrive under solution treatment guides selecting materials that maximize performance post-machining.

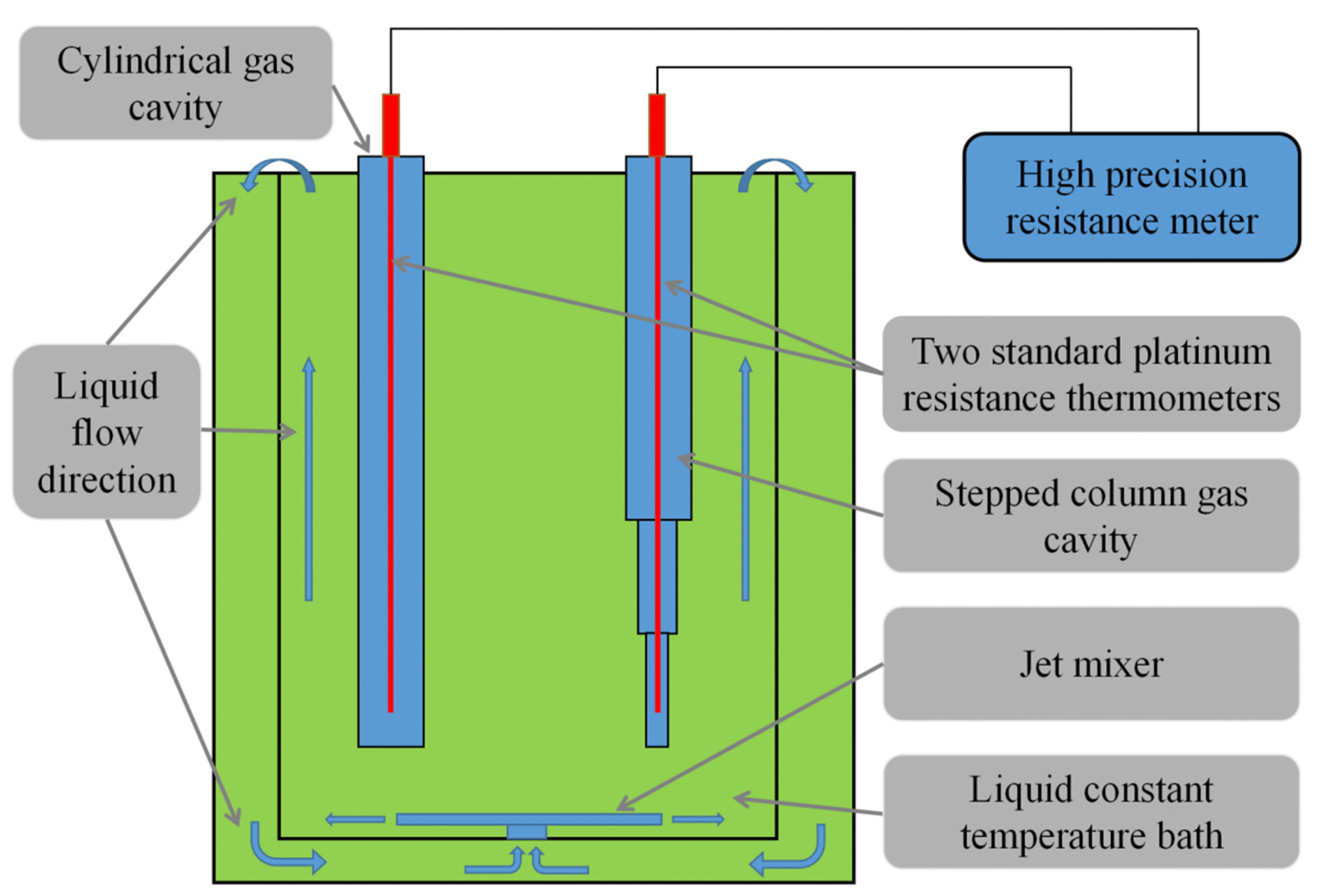

What Temperature and Cooling Parameters Are Critical for Effective Solution Treatment?

Temperature precision plays a pivotal role. Getting it right means the difference between success and failure.

Effective solution treatment requires carefully regulated temperatures based on the alloy. Incorrect settings can lead to uneven material properties or undesirable distortions.

Understanding critical parameters is key. For instance, aluminum alloys require specific temperature ranges between 940°F and 980°F, followed by rapid quenching. This prevents precipitate reformation, maintaining enhanced metal properties. Cooling methods, whether water or air quenching, affect the final material structure, making precise control essential for achieving desired outcomes.

How to Select the Right Solution Treatment Process for Your CNC Machined Components?

Selecting the right solution treatment process isn’t arbitrary. It requires understanding the components’ operational demands and material behaviors.

Each application demands specific properties. Matching these with the right treatment ensures optimal performance, longevity, and reliability.

Establish criteria based on the application's stress factors, environment, and material composition. For systematic selection, use a table to compare:

| Alloy Type | Temperature Range | Cooling Method | Benefits |

|---|---|---|---|

| Aluminum 2xxx | 940°F - 980°F | Water Quench | Increased strength |

| Magnesium Alloy | 700°F - 750°F | Air Quench | Enhanced ductility |

It exemplifies how each parameter influences material properties, guiding you in making informed decisions for your CNC machined parts.

Conclusion

Solution treatment is essential in enhancing machined parts, offering improved strength and performance. By understanding its nuances, you can leverage it for high-quality, durable components.