Are you wondering what the fuss is about when it comes to the tight fit and loose fit in CNC machining?

You're not alone!

In this post, we'll go over the advantages and disadvantages of both a tight and a loose fit, and what you should keep in mind when making your final decision.

So read on!

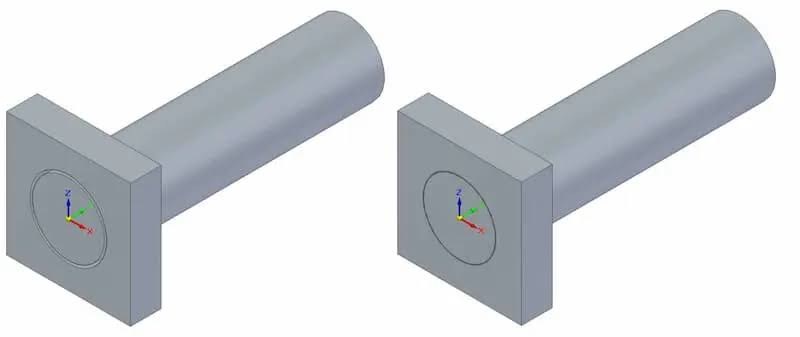

What is Tight Fit?

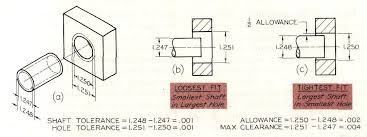

A tight fit in CNC machining is a form of fit in which two mating parts are intended to fit together with very little space separating them. This indicates that there is not much space between the two parts, and as a result, in most cases, it is necessary to press or force them together in order to achieve a proper fit.

Wherever there is a need for a great deal of accuracy and precision, such as in precision equipment, tight fits are frequently employed. Because of their tight fit, the components are kept in place without any wiggle. It is challenging to achieve a tight fit when the components must be manufactured with such minor tolerances.

What is Loose Fit?

A loose fit is a form of fit in CNC machining where there is more space between the mating parts. In other words, the tolerance between the two components is greater, and assembly doesn't require much muscle.

When a little bit of wiggle or play is desired, as in furniture or consumer products, loose fittings are the way to go. They allow for some wiggling and moving around of components, so you can bend and move with ease. Yet, they might not be as reliable or safe as a snug one.

Benefits of Tight Fits

CNC machining relies on precise and accurate fittings to produce high-quality results in a variety of contexts. Tight fits in CNC machining have many advantages, some of which are discussed below. These include higher productivity, greater dependability, and enhanced durability.

Improved Performance

A better fit often means better efficiency. When two parts that go together fit tightly, they don't move or play with each other in ways that aren't intended. This makes sure everything operates efficiently and without wasting any power. This is especially crucial in fields where precision and accuracy are essential, such as in aircraft, medicine, and the manufacturing sector.

Increased Reliability

Additionally, a tight fit can improve a system's dependability. If two pieces are a snug match, they will be less likely to wear out over time. Therefore, there is less chance of malfunction or breakdown, making for a more stable and durable option. In high-performance contexts, such as medical equipment, aircraft, and others, reliability is crucial; this is especially essential.

Better Resistance to Wear and Tear

Additionally, tight fits can offer superior durability. The risk of wear and tear from movement and friction is reduced when two components match snugly together. This may increase the components' durability and reduce the frequency with which they require maintenance or replacement. This is crucial in situations involving high loads, automobiles, and heavy machinery, among others, where wear and tear is a major worry.

Greater Stability

Greater stability is another advantage of tight fits. When two pieces fit together tightly, they are less likely to move or shake against each other. Consequently, the outcome may be more precise, and the system's stability may increase. This is of vital importance in fields where a great deal of stability is needed, such as medicine, aircraft, and precision machinery.

Enhanced Safety

Last, tight fits can make people safer. A close fit between two components reduces the possibility of separation or disengagement during use. This can offer a safer option and help avoid accidents and injuries. This is especially crucial for high-performance uses like medical equipment, aircraft, and others where user safety is essential.

Benefits of Loose Fits

Even though tight fits have a lot of benefits, loose fits can also be useful in CNC machining for a variety of tasks. Several advantages of loose fits will be discussed here, such as their adaptability, simplicity of construction, and low potential for mechanical failure.

Flexibility

Flexibility is one of the main advantages of a loose fit. There is some movement or play when there is some space between two sections. Useful in places where motion is required, like on hinges, moving doors, and other household items. As a result of their ability to accommodate thermal expansion and contraction, loose fittings are also useful in structural uses.

Ease of Assembly

Loose-fitting parts are also easier to put together. When there is some space between two components, it is much simpler and quicker to put them together. This can speed up and make easier the assembly process, also cutting down on labor costs altogether.

Reduced Risk of Damage to Parts

Loose fittings can prevent components from being damaged as well. There is less risk of wear and tear from movement and friction when two components fit together loosely. This can lengthen the components' service life and cut down on maintenance costs. In consumer goods, where parts tend to wear out quickly and be expensive to replace, this is of utmost importance.

Cost-Effective

Additionally, loose fits can save money. A loose fit between two components means less precision manufacturing is required, which lowers production costs. This may be useful in situations where accuracy is not essential, such as in consumer goods and non-essential structural uses.

Reduced Risk of Binding

Last but not least, looser suits can lessen the possibility of binding. When two parts are forced too closely together, there is a possibility that they will combine, which can result in a malfunction. This risk can be lessened if there is some space between the parts.

Examples of Applications for Tight and Loose Fits

Both tight and loose fits are useful choices in CNC machining, each with its own benefits and drawbacks. Here we will look at some typical uses for both tight and loose fittings.

Examples of Applications for Tight Fits

- Aerospace Applications: When precision is of the greatest priority, such as in aerospace uses, tight fits are frequently used. For optimum performance in applications like jet engines, it's necessary to have components that fit together tightly.

- Medical Devices: Precision and dependability are essential in the design of medical equipment, so tight fits are commonly used in this industry. This covers a range of issues where the components must closely fit together to ensure optimum performance and avoid failure, such as implantable devices.

- Precision Machinery: Tight fits are frequently used in precision equipment, where stability and accuracy are crucial. Applications like high-precision measuring devices and mechanical tools fall under this category.

- Automotive and Heavy Equipment: Tight fits are commonly used in the automotive and heavy-equipment industries because of the high frequency with which these components experience wear and strain. Engines, transmissions, and drivetrains are all examples of useful uses.

- Robotics: In robotics applications, where precision and reliability are paramount, tight fits are frequently used. Examples of this are robotic limbs and grippers.

Examples of Applications for Loose Fits

- Consumer Products: Loose fittings are frequently used in consumer goods because of the importance of adaptability and quick assembly. Hardware like door hinges and cabinet slides are examples of this category.

- Structural Applications: Loose fittings are frequently used in structural applications because of the potential for heat expansion and contraction. This includes uses for things like houses, bridges, and other structures.

- Bearings: When a certain amount of mobility or play is required, such as in a bearing application, a loose fit is typically used. Ball bearings and roller bearings are just two examples.

- Electrical Connectors : In order to allow for growth and contraction due to temperature changes, electrical connectors are typically designed with a loose fit.

- Piping and Plumbing: Loose fittings are frequently used in the plumbing and piping industries because of the potential for thermal growth and contraction. Water, gas, and sewage line construction tasks are just a few examples where this could be useful.

Factors to Consider When Choosing a Fit

When using computer numerical control (CNC) tools, it is crucial to have a good fit. Most factories today use CNC machines, and it's crucial to use the correct one for the job. We'll discuss how to select the ideal fit for CNC machines in this post.

Tolerance Requirements

When deciding on a fit for CNC machines, tolerance standards are the primary consideration. The term "tolerance" is used to describe the range of allowable variance in the dimensions of a given component. To ensure that the final product is of high quality, CNC machining requires that the fit be within the designated tolerance. So, it's important to choose a fit that works within the design's tolerances.

Material Properties

When picking a substance to use in CNC machines, the material's properties are also crucial. A material's rigidity, ductility, and elasticity can all have an impact on how well it fits. Different materials have different fitting requirements. For example, a softer material might need a looser fit, while a more rigid material might need a tighter fit. To get the best results, it's important to choose a size that fits the material.

Environmental Factors

The selection of a suitable fit for CNC machines can also be affected by environmental variables. Changes in temperature, humidity, and other environmental factors can cause the material to either grow or shrink, which can make it not fit right. It is therefore essential to choose a fit that is suitable for the operating circumstances in which the component will operate.

Manufacturing Process

How a product is made can also play a role in determining the best CNC machine settings. Machining factors that can impact fit include machine type, cutting tools, and machining speed. Therefore, it is crucial to think about the production process when choosing a fit to make sure it is suitable for the process.

Design Considerations

Last but not least, design should be considered when choosing a fit for CNC machines. Depending on the part's construction, its intended use, and its practical requirements, a suitable fit can be selected. It is crucial to choose a fit that satisfies the design specifications for optimum performance and usefulness.

To ensure high-quality finished products, CNC machines need to be fitted appropriately to ensure a good fit. You can choose the best fit by considering these factors.

Frequently Asked Questions (FAQs)

How does a loose or tight fit affect the finished product's performance?

The functionality of the final product may be greatly affected by how well its components work together. An improper fit can increase friction and make assembly more challenging, while a too-loose fit can lead to premature wear or a loss of accuracy. Choosing the right size is crucial for peak efficiency and effectiveness.

Why is it important to select the right fit in CNC machining?

Picking the correct size and shape is crucial for successful CNC machining. Properly fitting components improve a product's efficiency, longevity, and dependability, while loose ones compromise its performance and safety. It's important to take into account all relevant factors and choose the most suitable option for each application.

How does the choice of fit affect the cost of CNC machining?

CNC milling prices can vary widely depending on the selected fit. A tighter fit could require more accurate machining or extra post-processing steps, which could raise the production cost. A cheaper production cost may be achieved through a looser fit, which requires less precision and possibly fewer post-processing stages.

Final Words

Tight fit and loose fit are terms used to describe the amount of tolerance or clearance between two mating components in CNC machining.

In a tight fit, there isn't much space between the pieces. In a loose fit, there is more space between the pieces.

In order to decide whether you need a tight fit or a loose fit for your application, you must determine what your needs are.

Tight fits are used when parts need to line up perfectly and move very little. Loose fits are used when parts need to be flexible or move around.

To find the right fit for a given application, you must consider the design and tolerance requirements carefully.