Are you struggling with gear selection for your mechanical system? Poor gear choice leads to inefficiency, excessive noise, and premature failure—potentially causing expensive downtime and repairs.

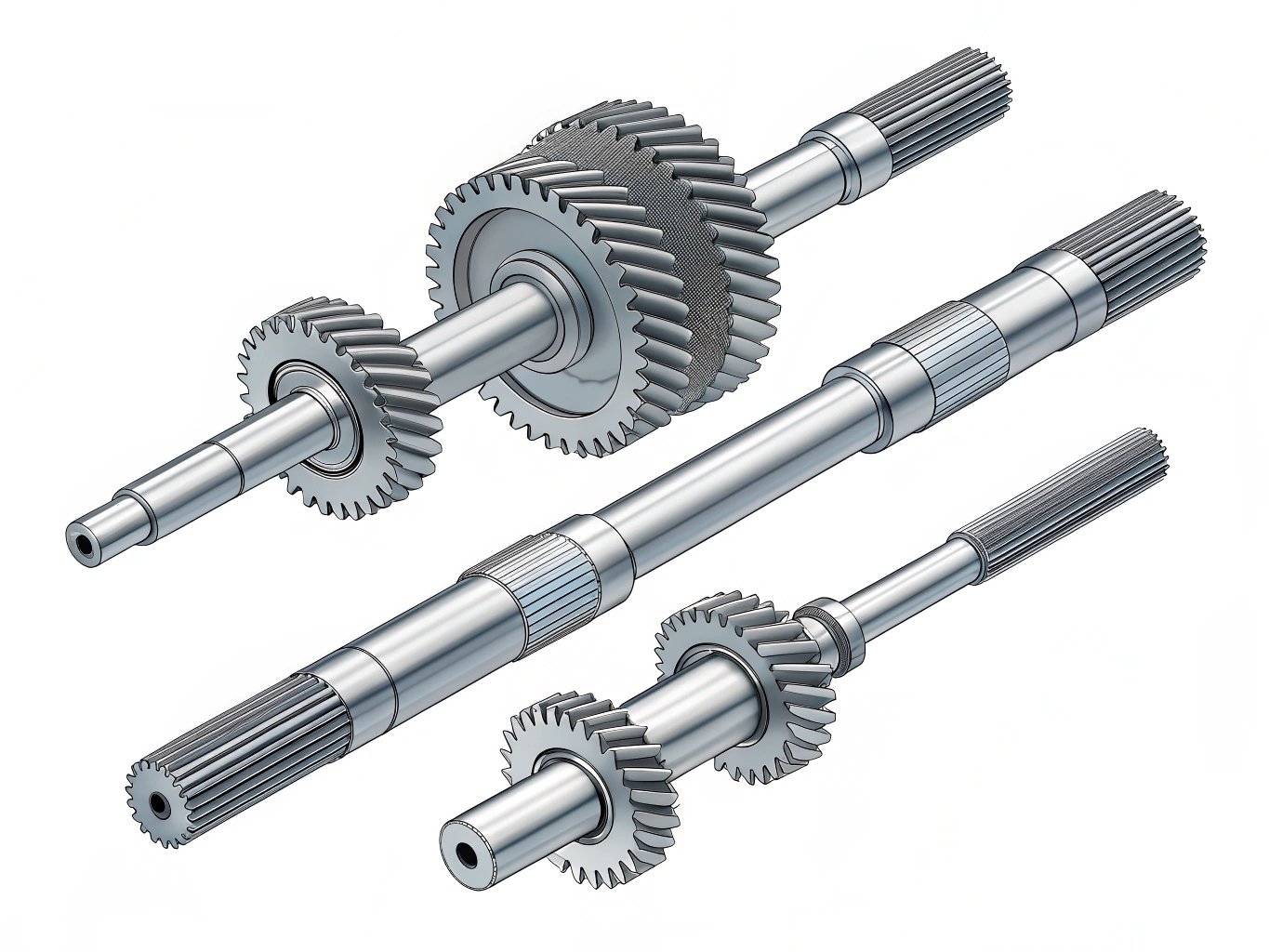

Gears transmit motion and power between rotating shafts, coming in various types including spur, helical, bevel, and worm gears. The right selection depends on shaft position, speed requirements, load conditions, and space constraints. Understanding each gear's strengths helps optimize your mechanical system's performance.

When I first started in the machining industry, I made the mistake of using standard spur gears for a high-load application that required smooth operation. The result was excessive noise and premature wear. This experience taught me that proper gear selection is fundamental to any mechanical system's success. Let's explore the different types of gears and how to select the most appropriate one for your specific needs.

In mechanical design, how do you choose the right gear type based on the position of the shaft?

Do your shafts keep changing position? Selecting the wrong gear for your shaft arrangement can lead to power losses, increased wear, and even complete system failure.

The relationship between shaft positioning and gear selection is straightforward: parallel shafts typically use spur or helical gears, intersecting shafts require bevel or miter gears, and non-intersecting, non-parallel shafts need worm gears or hypoid gears. This fundamental relationship determines initial gear selection.

Shaft positioning is the primary factor that determines which gear type will work in your system. Each configuration demands specific gear geometry to effectively transfer power while maintaining proper contact between teeth.

For parallel shafts, spur gears offer the simplest and most cost-effective solution. They feature straight teeth aligned parallel to the axis of rotation, making them easy to manufacture and maintain. When noise reduction and smoother operation are priorities, helical gears become the better choice despite their higher cost. The angled teeth of helical gears engage gradually, reducing impact forces and operating noise.

When dealing with intersecting shafts (typically at 90° angles), straight, spiral, or zerol bevel gears are the standard solutions. Straight bevel gears work well for low-speed applications, while spiral bevel gears handle higher speeds and heavier loads. Zerol bevel gears offer a middle ground with curved teeth but zero spiral angle.

For the most challenging configuration—non-intersecting, non-parallel shafts—worm gears or hypoid gears become necessary. Worm gears excel at high reduction ratios in a compact space but sacrifice efficiency due to sliding action. Hypoid gears, similar to spiral bevel gears but with offset axes, provide smooth operation and high strength at the cost of manufacturing complexity.

| Shaft Position | Recommended Gear Types | Key Benefits | Typical Applications |

|---|---|---|---|

| Parallel | Spur, Helical, Herringbone | Direct power transfer, efficiency | Conveyors, pumps, general machinery |

| Intersecting | Bevel, Miter | Change direction of rotation | Automotive differentials, hand drills |

| Non-intersecting, Non-parallel | Worm, Hypoid, Crossed helical | High reduction ratios, compact design | Elevators, steering systems, heavy machinery |

What are the differences in the working principle and technical characteristics of different types of gears?

Are noise, efficiency, and load capacity critical concerns in your system? Choosing a gear without understanding its working principles can result in premature failure, excessive power consumption, and unreliable operation.

Different gear types operate on unique principles: spur gears transfer motion through direct tooth contact; helical gears use angled teeth for smoother engagement; bevel gears change the axis of rotation; and worm gears provide high reduction ratios through sliding contact. These principles directly affect performance characteristics.

The fundamental differences between gear types stem from their tooth geometry and how they mesh together. This directly influences their performance characteristics including load capacity, efficiency, noise levels, and suitability for various applications.

Spur gears operate on the simplest principle—straight teeth engage directly along their full width simultaneously. This creates efficient power transfer (up to 98%) but also generates significant noise and vibration as teeth impact each other. Their straightforward design makes them the most economical option for many applications, though they're limited to parallel shaft arrangements and moderate speeds.

Helical gears, with teeth cut at an angle to the face of the gear, operate on a different principle. The angled design creates gradual engagement as teeth mesh progressively rather than all at once. This reduces noise and vibration substantially but introduces axial thrust forces that must be managed with appropriate bearings. The sliding action between teeth slightly reduces efficiency (typically 94-98%) compared to spur gears but allows for higher speeds and smoother operation.

Bevel gears work by transferring motion between intersecting shafts. Their conical design with teeth that taper toward the apex allows force to be distributed over a larger area. Spiral bevel gears add a curved tooth pattern for even smoother operation and higher load capacity, making them ideal for automotive differentials and other high-load applications requiring direction changes.

Worm gears operate on a completely different principle, with a screw-like worm driving a wheel. This sliding action enables extremely high reduction ratios in a single stage (often 20:1 to 300:1) but results in lower efficiency (typically 40-85%) due to friction. The inherent sliding creates a self-locking mechanism in high-ratio configurations, preventing backward driving—a useful safety feature in lifting applications.

| Gear Type | Working Principle | Efficiency | Noise Level | Load Capacity | Speed Capability |

|---|---|---|---|---|---|

| Spur | Direct tooth contact | 98-99% | High | Moderate | Low to Medium |

| Helical | Gradual angled contact | 94-98% | Low | High | Medium to High |

| Bevel | Conical tooth engagement | 95-97% | Medium | High | Medium |

| Worm | Sliding screw action | 40-85% | Very Low | Moderate | Low |

| Planetary | Multiple path load sharing | 95-97% | Medium | Very High | High |

What are the advantages and disadvantages of standard gear and custom gear? When to choose which?

Is budget your only concern when choosing between standard and custom gears? This shortsighted approach can lead to poor system performance, compatibility issues, and ultimately higher long-term costs through inefficiency and premature replacement.

Standard gears offer cost efficiency, immediate availability, and known performance characteristics but may require design compromises. Custom gears provide optimal performance, perfect application fit, and proprietary advantages at higher cost and longer lead times. The choice depends on application criticality and budget constraints.

The decision between standard and custom gears represents one of the most consequential choices in mechanical design, affecting everything from performance to project timelines and budgets.

Standard gears, available from catalogs with predefined specifications, offer significant advantages in terms of cost and availability. These mass-produced components benefit from economies of scale, typically costing 30-60% less than their custom counterparts. With immediate or short-lead availability, they enable faster project completion and simpler replacement strategies. Their standardized dimensions and performance characteristics are well-documented, removing uncertainty from the design process.

However, standard gears often force designers to compromise on optimal performance. I recall a project where using standard gears required us to modify other components and enlarge the housing—ultimately negating the initial cost savings. Standard options may not offer the ideal tooth profile, material, or precision grade needed for specialized applications. This can lead to reduced efficiency, increased noise, or shortened lifespan in demanding environments.

Custom gears, while more expensive and time-consuming to obtain, provide optimized solutions for specific applications. They allow precise specification of tooth profiles, materials, heat treatments, and tolerances. For a recent high-precision automation project, we designed custom gears that increased system efficiency by 12% and extended maintenance intervals by 40% compared to standard options—delivering significant long-term value despite higher initial costs.

When deciding between standard and custom options, consider these factors: application criticality, performance requirements, space constraints, load characteristics, and budget limitations. For non-critical applications with standard loads and sufficient space, catalog gears often make perfect sense. For mission-critical systems, tight spaces, unusual loads, or specialized environments, the investment in custom gears typically pays dividends through improved performance and longevity.

| Factor | Standard Gears | Custom Gears | Decision Point |

|---|---|---|---|

| Cost | Lower initial investment | Higher initial cost | Budget constraints vs. long-term value |

| Lead Time | Immediate to weeks | Weeks to months | Project timeline flexibility |

| Performance | Good for typical applications | Optimized for specific needs | Application criticality |

| Design Flexibility | Limited to available options | Nearly unlimited options | Unique requirements |

| Replacement | Simple, predictable | May require custom reorder | Maintenance strategy |

| Knowledge Required | Catalog selection skills | Extensive engineering expertise | Available technical resources |

Conclusion

Selecting the right gear type requires understanding shaft positions, working principles, and whether standard or custom options best suit your application. Proper gear selection maximizes efficiency, extends system life, and optimizes performance for your specific mechanical needs.