If you are familiar with the manufacturing process of some of the various products we employ in our everyday lives - from the simple utensils to the complex machineries - the term Custom CNC machining should not be strange to you.

CNC machining would easily make the top two of any lists ranking the different methods adopted in the manufacturing of custom parts. And, it wouldn't even settle for second position in any of them.

This is not an exaggeration.

With CNC machining, you can get your bespoke products delivered to you in a matter of days, wherever you are in the world. Thanks to the CAD modeling technology, and the fact that we can conveniently make and receive orders from anywhere in the world.

China is up there with the United States as the leading manufacturing countries in the world today. So, it is not a mere coincidence that it is the principal supplier of various CNC machining services across many countries. The several machining and prototyping services shops in China are designed to serve the needs of both the locals and the international manufacturing market.

Yet, many potential buyers from oversea still find it difficult to find the perfect Chinese machining company or trading factory to cater for their demands. Whether you are in this category or not, this post is sure to guide you to find a suiting partner for your Custom CNC milling services in China.

Read till the end!

What is CNC Machining?

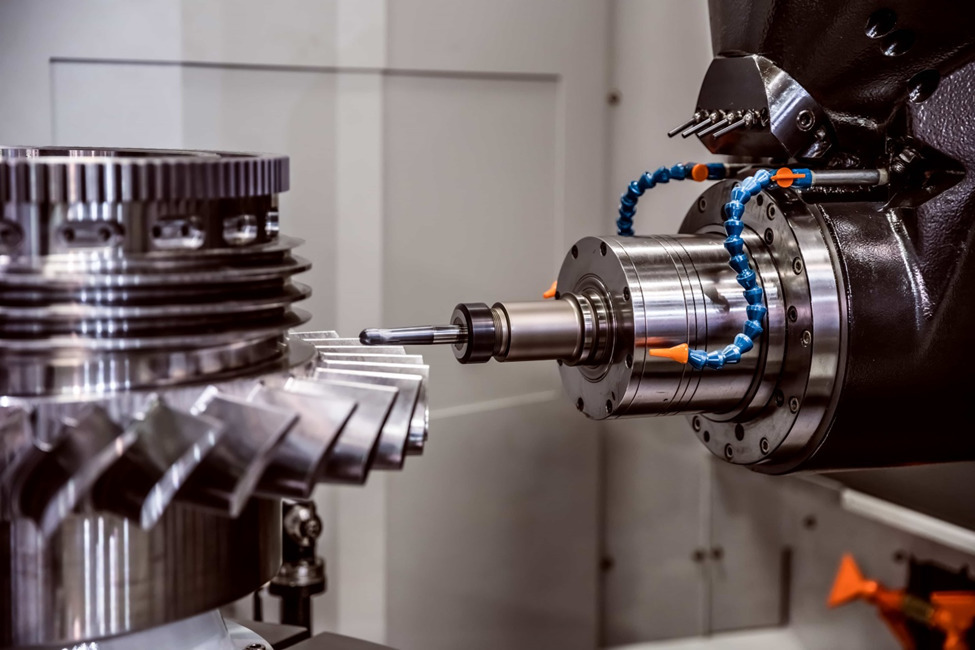

To begin with, Computer Numerical Control (CNC) is an automated method of manufacturing. This implies that, it requires little or no human effort to function. Instead, what it adopts is a set of programming codes, which when fed into the system will spur the repetitive motion of this custom-designed device to bring about the creation of useful components from a material.

Unlike the manual method where live operators are required to utilize operational buttons, levers, or wheels to make the system work, this process is automatic and functions completely personnel-free.

Rather, they operate with a numerical control system wherein computers are programmed with a software – known as G-code. What the G-code does is to regulate the corresponding velocity, feed rate, and overall coordination of the machine.

CNC machines are generally employed where highly consistent precision and pin-point accuracy are the main objectives. It is classified as a reductive method of manufacturing because it involves gradual chopping off the outer layer of the solid piece to be produced in a process that will culminate in a fine machined end-product.

In short, this how it works: Upon activation, the CNC system conceives a synchronized 2D or 3D drawing which ignites a positive feedback cycle that will translate the drawing to a computer code for the system to utilize on the corresponding component.

It is however necessary for the operator in charge to establish the assurance of an error-free coding process by running a check before inputting the program.

A CNC machine may look from a distance like an ordinary assembly of computer parts, but it is beyond that. Here are three highlights that separate it from all other types of computation:

- A unique set of software programs and consoles (that can be run repeatedly to produce the same effect on multiple devices),

- Revisable CNC codes, and

- Large computational capacity

The machine functions totally based on the code it receives. As such, the performance of the machine may be linked with the brilliance of the programmer.

This machining process was employed specifically in vital areas like aerospace, automotive, agriculture, and plastic production but it is now of great use throughout the manufacturing sector of the economy.

Other areas that utilize CNC machines include: mining, food & beverage, and the clothing sector where the machines are equipped to drill holes, slit the fabric and sew the clothing. It is almost impossible to make a list of all the applicable functions of CNC machines.

Concept of Custom CNC machining

Custom CNC machining is what makes many of our everyday cutting, carving, broaching, lapping and drilling operations possible. It has profound applications in several large sectors including; Aerospace, Automotive, Construction, and Agriculture.

This method, which started out by using punched tape cards, has now grown into a specialized process that literally robotize the fabrication process of constructive machine parts, by adopting a set of programming codes.

It employs a reductive method of manufacturing that involves chopping off and assembling the outer layer of a solid piece in creating a fine machined end-product. The reverse method is employed in alternatives like liquid injection moulding and 3D printing. Here, the methods adopted are additive or formative in nature.

Regardless of the diverse approach employed by different Custom CNC machining companies, the underlying principle remains the same:

- The fabricator initiates the process by creating the computer-aided design (CAD),

- He feeds the design into the system,

- The system converts it to a set of CNC programs,

- The CNC machine accepts this set of computations,

- The final product is created.

Custom CNC machining is a sought-after method of manufacturing mainly because it makes it possible to create quality, accurate and precise bespoke components through a penny-wise process that is enticing to customers all over the world. But it shouldn't always come down to the fineness of the products.

Let's have a brief look at some applicable areas of custom CNC machining, and why it is a preferred method of manufacturing in those areas over the available alternatives:

- Custom machining is applicable where the products to be produced are novel or one of a kind. In many cases, these components are scarce to find. Sometimes, they aren't even available at a reasonable price. Custom CNC machining is sure to get the job done whether the intended creation is a simple or complex one.

- Alternatively, the component may be quite common, but needs an extra feature, like an engraving of unique words or designs. It is quite common to see businesses turn to custom CNC machining for these custom designs on their products.

- Custom machining is used to produce specialized components that are intended for a particular project or pertaining to a particular field.

- In cases of emergency, quality parts can be made quickly from their pre-existing digital files through custom machining. Whether it is plastic machining or metal machining (of aluminum, bronze, brass, stainless steel, etc.), custom machining is equipped to perform the exact functions of the sought-after CNCs.

- Custom machining is sometimes used as an alternative to CNC machining because it is cost-effective. With a fixed budget, a product designer may struggle to pay the cost incurred from ordering a batch of 500 plastic components via an injection molding company. In this case, he would prefer to opt for a more cost-effective method in order to boycott the expensive cost of CNC machining companies.

- Aside the cost, if the product designer is ordering in small quantity, and thus, desires a significantly fast method of order, then, custom machining should be the go-to option over alternatives like casting, molding, sheet metal fabrication, or 3D printing, since it is very fast and easy to setup.

Any CNC shop that's planning to set up custom machining parts would have to be prepared to cater for the range of materials that comes with the process. These materials include equipments like some versatile machines, toolheads and ancillary equipment that suits the corresponding products.

Moreso, each customer's needs require a unique operational approach to match them. Therefore, machine shop would also be required to offer a range of options that meet the customer's specific needs.

As such, machine shops require a consistent flow of supply of materials that applies to a wide range of customer's needs. They will have to come up with new ideas, dabble with new models, and sometimes they are required to create new programs for different jobs. As each job can vary so wildly, the client's ideas in the development are necessary.

Generally, the means of customization can be grouped into four parts depending on the level of input from the machine shop and the client:

In the first group: The buyer would provide a drawing or a draft of the specification of the intended output, and the manufacturing company will act on it. In such cases, the client knows clearly the part he desires, and can provide a 3D sketch of it.

The second group: Involves a buyer that is not very clear about the part he desires. The buyer may have the conceivable idea but cannot provide a 3D sketch of it. This is where the machine shop comes in. It acts on the customer's ideas to create the custom design.

The third group: The manufacturing company creates a base part that can be modified to suit the customer's specific design. The edge this method has over other methods is that the company can produce a good number of a product within a short time just by tweaking the base point. The limitation is however that, while it makes the job of manufacturers easier, it has restricted the buyers' choice.

In the last group: The company creates a number of tailor-made options for the customers to choose from. The variation in the products may be as simple as an aesthetic re-packaging, or simply changing the colors. This method may be seen as fast but it reduces the level of customization to the minimum.

What are the types of custom CNC machining?

It is worth noting again that CNC machining has profound applications in several industries including: Aerospace, Automotive, Construction and Agriculture. As such, examples of the finished products that have been formed through the process over the years include the following:

- Aeroplane engines

- Automobile frames

- Hydraulic components

- Screws

- Shafts

- Surgical tools

- Surgical tools

Custom CNC machining employs either a chemical, mechanical, thermal, or electrical process to carry out the gradual removal of the outer layer of the solid piece.

These processes can be broadly classified into the milling, drilling, and turning operations.

Milling: Some movements cause the CNC machine's cutting equipment to cut out some layers of the materials.

Drilling: Involves drilling of vertically aligned cylindrical holes of similar diameters in the workpiece as part of chopping off the outer solid layer. Alternatively, CNC machine shops can also employ operations like countersinking, counterboring, tapping, and reaming to drill the material angularly.

Turning: Involves feeding the piece with a tool that removes the layers by rotating holding bars of material in a chuck until the desired product is obtained.

CNC machining services in China

CNC machining is a complex and a relatively expensive method of manufacturing. This is why it is very common to see new or small businesses seeking opportunities to access and utilize the CNC machines without having to incur a huge debt in the process. What they do is to outsource this service to big machining factories in a contractual agreement that circumvents the cost of skilled labor and machine acquisition for these businesses.

China boasts of a good number of swift simulation and prototyping shops that allows you to get free estimation and expert advice on your manufacturing design through their 24/7-active customer service. All you have to do is to simply upload your design files and highlight your goals for the project, and they will respond immediately.

By the end of this article, you would have seen why partnering with a custom CNC milling company in China for production of custom parts and swift prototyping is the best option. But firstly, I have complied a list of factors to consider when choosing a company to partner with for your custom CNC milling in China. Have a look:

1. Certifications:

It is important to check out the certification history of the company before you outsource your custom CNC milling service to them. For instance, if you intend to serve the medical industry with your order, it is advisable that you contact a company with relevant history and testimonials in that field.

2. Communication:

Secondly, it is important to establish a good rapport with the company before diving into the contract. It pays to straighten out every of the contract's detail and intricacy before endorsing it.

3. Production Capabilities:

It is pointless to partner with a company that does not have the required equipment and facilities to cater for your needs. Whether it is custom milling or CNC turning you need, ensure that the company is well-equipped with the production hardware to carry out the job.

4. Quality Control:

As part of ensuring your machined end-product are of the highest standard, it is advisable to choose a partner that practice some quality inspection protocols before sending these prototypes out to you.

5. Prototype trial:

Lastly, you can order a prototype of the part you want as a trial to enable you ascertain the standards of the machining company and test if they meet the requirements for your specific product.

The Advantages of customizing CNC milling parts from China

Having understood the basic concept of custom milling, you might start to wonder why you should outsource your custom milling needs to China.

Firstly, custom production is generally affordable in China. This is why foreign companies around the world particularly across Europe and USA turn to rapid prototyping shops in China for a cost-effective service. Although some countries like Vietnam offer prices that are even cheaper than China's, their two decades of active service in the industry, and the significant amount of 'best brains' the country affords various areas of the technology sector are some of the reasons it is usually the preferred option.

Also, custom milling companies in China are reputable for fast turnaround time. When coupled with the fact that their services are not bank-breaking, it implies that you can acquire less expensive prototypes within a short period.

However, I cannot but consider the logistical challenges that comes with outsourcing your custom cnc milling services to a Chinese company:

The diversity of language is usually a major problem that exists between swift prototyping companies in China and English buyers. Perhaps the miscommunication challenge is only a minor problem. Some licensing and copyrights complications can constitute a serious legal problem in a foreign country where you are not very familiar with their custom.

Additionally, you cannot be assured of standard and quality products from all custom milling companies in China. While some prototyping companies employ sophisticated facilities that will yield good quality products some others are still very much in the business of supplying low-quality products to buyers.

In short, outsourcing your CNC custom milling service to China comes with a lot of benefits and challenges. Therefore, weigh your options appropriately before opting for any custom milling company in China.

CONCLUSION

Some of China's leading rapid prototyping companies have the traditional advantage of affordable cost and fast turnaround time. But, not all of these companies go extra miles to proffer solutions to some of the common problems associated with outsourcing custom CNC milling parts to China. However, some of these companies have an array of 4-axis and 5-axis machines that an average Chinese company does not have access to. These machines allow the companies to consistently create complex and highly precise products.

They also have employees that are fluent in English. Thus, allowing them to overcome any language barrier militating against successful partnership.

Thirdly, you need to be aware that security is not promised with some of these companies. Only those who employ a third-party security agency can guarantee safety in every aspect of production and transportation.

In general, what outsourcing custom milling service to China offers is outstanding value for products across a wide range of industries.