Cutting fluids play a critical role in CNC machining by improving both process efficiency and final part quality. These fluids are applied during metal cutting to reduce heat, friction, and tool wear while maintaining dimensional accuracy. Without proper cooling and lubrication, excessive temperatures at the cutting zone can cause rapid tool degradation, poor surface finish, and geometric distortion in the workpiece.

Cutting Fluids in CNC machining

The choice and condition of cutting fluids directly influence surface integrity and tool life. Factors such as fluid composition, concentration, and delivery method determine how effectively heat is removed and chips are cleared from the cutting area. When managed correctly, cutting fluids help extend tool performance, stabilize machining parameters, and ensure consistent part quality.

However, improper fluid selection, contamination, or inadequate maintenance can lead to reduced machining precision, corrosion, and health or environmental issues. Understanding how cutting fluids function, their types, and inspection methods is essential for optimizing machining outcomes and minimizing operational costs.

Fundamentals of Cutting Fluids

Cutting fluids are essential for maintaining thermal balance, lubrication, and cleanliness in CNC machining operations. Their effectiveness depends on chemical composition, application technique, and compatibility with both tool and workpiece materials. A well-chosen cutting fluid enhances tool performance, prevents premature wear, and improves part quality, while an unsuitable or poorly maintained one can cause dimensional errors and corrosion.

Purpose and Functions of Cutting Fluids

The main objectives of cutting fluids are to reduce heat generation, minimize friction, and aid in chip evacuation. Each function contributes to better surface integrity and longer tool life.

- Cooling: High cutting temperatures occur due to friction between the tool, workpiece, and chip. The cooling function removes heat from the cutting zone, maintaining a stable temperature that reduces thermal distortion and preserves tool hardness.

- Lubrication: Lubricants form a thin film between the cutting edge and material surface. This lowers friction, decreases cutting forces, and helps prevent built-up edge formation, which can damage surface finish.

- Chip Evacuation: Effective fluid flow assists in flushing chips away from the tool, preventing recutting and protecting the cutting edge from abrasion.

- Corrosion Prevention: Fluids contain additives that form protective films on the workpiece and machine components. This prevents oxidation and staining after machining.

By combining these functions, cutting fluids stabilize the machining environment, maintain process consistency, and minimize costly tool replacements.

Types of Cutting Fluids

Types of Cutting Fluids in CNC machining

The selection of cutting fluid depends on material type, cutting conditions, and environmental considerations. Each category provides specific advantages and limitations.

- Water-Soluble Fluids: These emulsions blend water and oil, providing strong cooling and moderate lubrication. They are commonly used in high-speed machining where temperature control is critical.

- Semi-Synthetic and Synthetic Fluids: Semi-synthetics balance lubrication and cleanliness, while synthetics contain no oil, offering excellent cooling and reduced residue. They are suitable for precision machining and automated systems that require low maintenance.

- Straight Oils: Also known as neat oils, these are undiluted petroleum or vegetable-based fluids with strong lubricating properties. They are ideal for low-speed, high-pressure cutting but generate more mist and heat compared to water-based alternatives.

Selecting the right fluid requires balancing cooling efficiency, lubricity, material compatibility, and environmental safety.

Mechanisms of Action

Cutting fluids function through two main mechanisms: lubrication and heat removal. Understanding these mechanisms helps optimize application methods and improve machining stability.

- Lubrication Effect: The lubricating film reduces direct metal-to-metal contact between tool and workpiece. This minimizes adhesion, wear, and surface tearing, especially in ductile materials like aluminum or copper alloys.

- Heat Dissipation: Fluids absorb and carry away heat generated by friction and plastic deformation. Efficient heat transfer lowers cutting temperature, reducing tool wear and maintaining surface quality.

A properly maintained cutting fluid system ensures that both mechanisms work in harmony, resulting in consistent machining performance, extended tool life, and superior surface finishes.

Impact of Cutting Fluids on Surface Integrity

Surface integrity is a key indicator of machining quality, influencing part performance, fatigue resistance, and dimensional stability. Cutting fluids play a direct role in shaping this outcome by controlling temperature, reducing tool–workpiece friction, and preventing microstructural damage. The correct type and concentration of fluid ensure a smooth finish and minimize defects such as surface burns, residual stresses, and cracks. Maintaining proper flow rate and nozzle positioning also helps keep the cutting area clean, which is critical for achieving consistent surface characteristics.

Using Cutting Fluids in CNC Machining

Factors Affecting Surface Finish

A well-controlled cutting fluid system stabilizes temperature and reduces mechanical stress during cutting. Both these aspects have a strong influence on the final surface finish.

- Temperature Control and Thermal Stability: Excessive heat during machining can cause thermal distortion and oxidation, leading to rough or uneven surfaces. Cutting fluids absorb and carry away this heat, maintaining uniform temperature across the cutting zone. This thermal stability helps preserve tool geometry and prevents thermal cracks on the part.

- Reduced Friction and Built-Up Edge Formation: High friction can cause the material to adhere to the cutting tool, forming a built-up edge (BUE). This phenomenon tears the surface layer, increasing roughness. Cutting fluids lower the friction at the contact interface, preventing BUE and ensuring a clean cutting action that improves texture and appearance.

A consistent surface finish reduces post-processing requirements, such as polishing or grinding, and helps maintain part precision.

Effect on Surface Roughness, Microstructure, and Residual Stress

Surface integrity extends beyond roughness; it includes microstructural changes and stress distribution beneath the surface. Cutting fluids influence all these parameters through temperature regulation and lubrication.

- Influence on Tool–Workpiece Interface: Stable lubrication decreases shear strain and adhesive wear at the interface. This results in lower tool vibration and better micro-finish. Smooth cutting reduces surface tearing and ensures uniform texture.

- Prevention of Surface Burns and Cracking: Without adequate cooling, the surface can overheat, causing localized melting or phase transformation. Cutting fluids maintain controlled thermal conditions, avoiding heat-affected zones or metallurgical alterations that compromise part durability.

- Control of Microhardness Variation: Excessive heat can harden or soften the material surface unevenly, creating stress gradients. Fluids distribute heat more evenly, maintaining consistent microhardness and improving fatigue strength.

Residual stresses are a hidden threat to precision components. Proper fluid management minimizes thermal gradients and tool pressure that induce such stresses.

Role in Dimensional Accuracy and Part Tolerance

Precision machining depends on maintaining close dimensional tolerances. Cutting fluids contribute to this by stabilizing both the cutting tool and the workpiece during operation.

- Reduction of Thermal Expansion and Distortion: As temperature rises, materials expand, leading to dimensional deviation. Cutting fluids reduce the temperature gradient between the tool and workpiece, limiting expansion and preserving geometry.

- Better Control of Surface Deviations: Consistent lubrication reduces tool wear, preventing cutting edge rounding that causes gradual dimensional drift. Regular fluid flow also removes chips effectively, avoiding recutting that can scratch or deform the surface.

By maintaining optimal cutting conditions, fluids ensure the final dimensions match design specifications and minimize the need for corrective machining.

Influence of Cutting Fluids on Tool Life

Tool life is one of the most critical performance factors in CNC machining. Every cut generates heat, pressure, and friction that gradually wear down the cutting edge. Cutting fluids reduce these effects by providing cooling and lubrication, directly influencing how long a tool maintains its geometry and cutting efficiency. A properly selected and maintained fluid can extend tool life significantly, allowing for longer production runs, fewer tool changes, and more stable part quality.

The effectiveness of cutting fluids depends on the machining operation, material type, and cutting parameters. Excessive heat or lack of lubrication accelerates wear, while correct fluid delivery ensures a controlled cutting temperature and smoother chip removal. This balance determines the durability and economic efficiency of the machining process.

Wear Mechanisms Reduced by Fluids

Cutting fluids act as a barrier between the tool and the workpiece, reducing the intensity of various wear mechanisms that occur at the cutting zone.

- Adhesive Wear: Occurs when the tool and workpiece material adhere under high temperature and pressure. The fluid minimizes adhesion by forming a lubricating film, reducing metal transfer and surface damage.

- Abrasive Wear: Hard particles in chips or the workpiece can scratch the tool surface. Cutting fluids help flush away these particles, minimizing abrasion and preserving tool sharpness.

- Diffusion Wear: At elevated temperatures, chemical elements may diffuse between tool and workpiece materials, weakening the cutting edge. Effective cooling from cutting fluids lowers the diffusion rate, maintaining tool hardness.

- Oxidation Wear: Oxygen in the air reacts with hot tool surfaces, forming brittle oxides that lead to chipping. Fluids act as a thermal and chemical shield, limiting oxidation and edge breakdown.

By addressing these wear modes, cutting fluids stabilize cutting conditions and ensure consistent tool performance throughout production cycles.

Heat Reduction and Tool Edge Stability

Controlling heat is essential for tool longevity. Excessive temperature softens cutting materials, alters coating adhesion, and leads to mechanical failure. Cutting fluids remove heat rapidly from the cutting zone, keeping both tool and workpiece within safe operating limits.

Consistent cooling ensures that tool edges maintain their designed hardness and shape, preventing early wear or plastic deformation. It also reduces thermal cycling, which can cause microcracks along the cutting edge. As a result, tools retain their geometry for longer periods, supporting precise, repeatable cuts even in high-speed operations.

Extended Tool Life and Cost Efficiency

Longer tool life translates directly into operational savings. Reducing tool change frequency minimizes downtime and improves productivity across the workshop. Stable tool performance also reduces scrap rates, ensuring uniform part quality from batch to batch.

In large-scale production, the cost of cutting fluids is relatively small compared to the savings from extended tool service. Proper fluid maintenance and delivery methods provide a high return on investment through reduced tool purchases, improved cycle times, and consistent machining output.

A well-managed fluid system, therefore, supports both technical and economic efficiency, forming a key part of sustainable CNC machining practices.

Flood vs. MQL vs. Dry Machining Performance

The application method of cutting fluids greatly affects heat removal, tool wear, and overall machining efficiency. Traditional flood cooling, modern Minimum Quantity Lubrication (MQL), and dry machining each have distinct advantages depending on the operation type, material, and production priorities. Understanding how these systems perform helps machinists balance cooling efficiency, environmental impact, and cost control.

Choosing the right approach requires analyzing factors such as cutting speed, tool material, chip load, and thermal behavior of the workpiece. While flood cooling offers superior temperature control, MQL and dry machining focus on sustainability and cost reduction. The right decision often lies in matching the process with material properties and desired part quality.

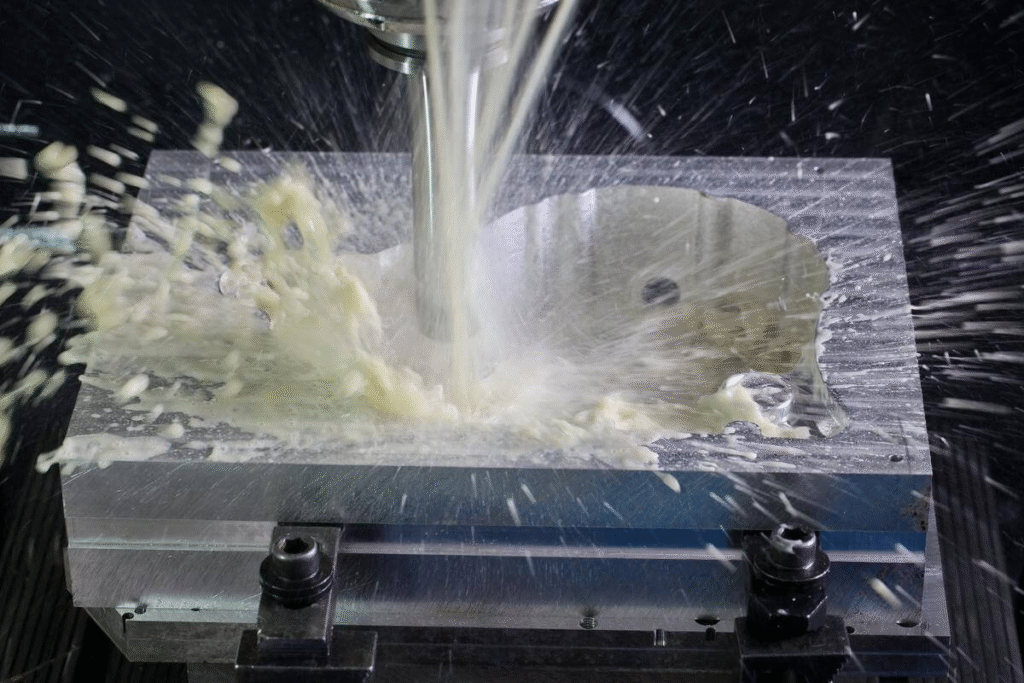

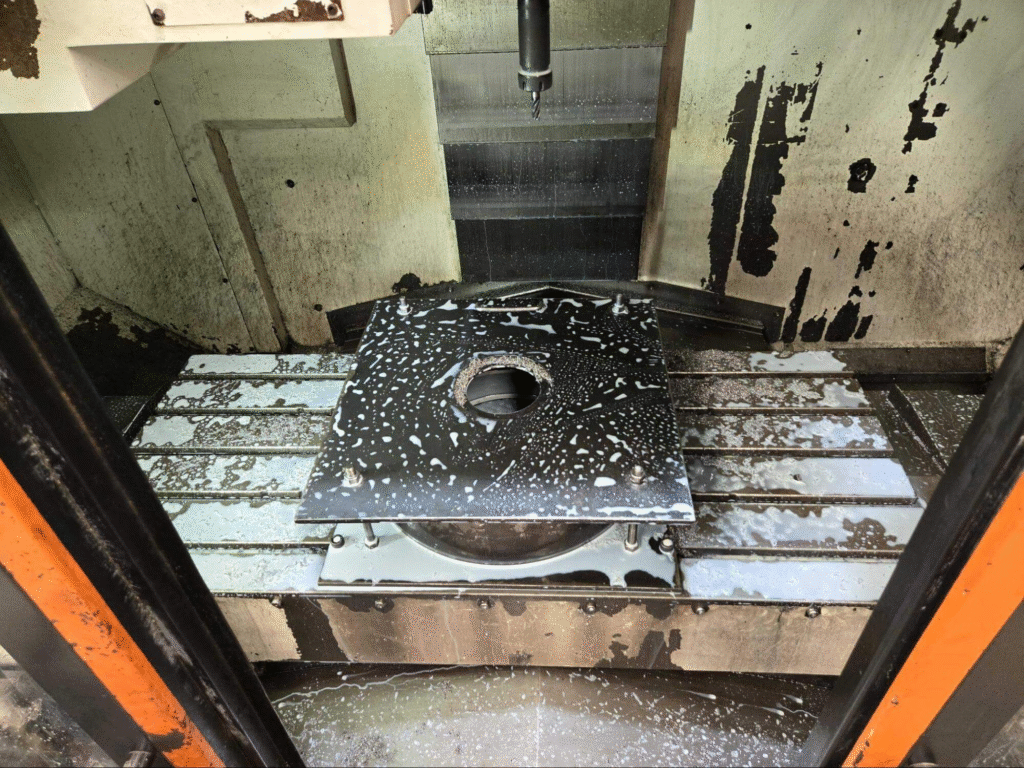

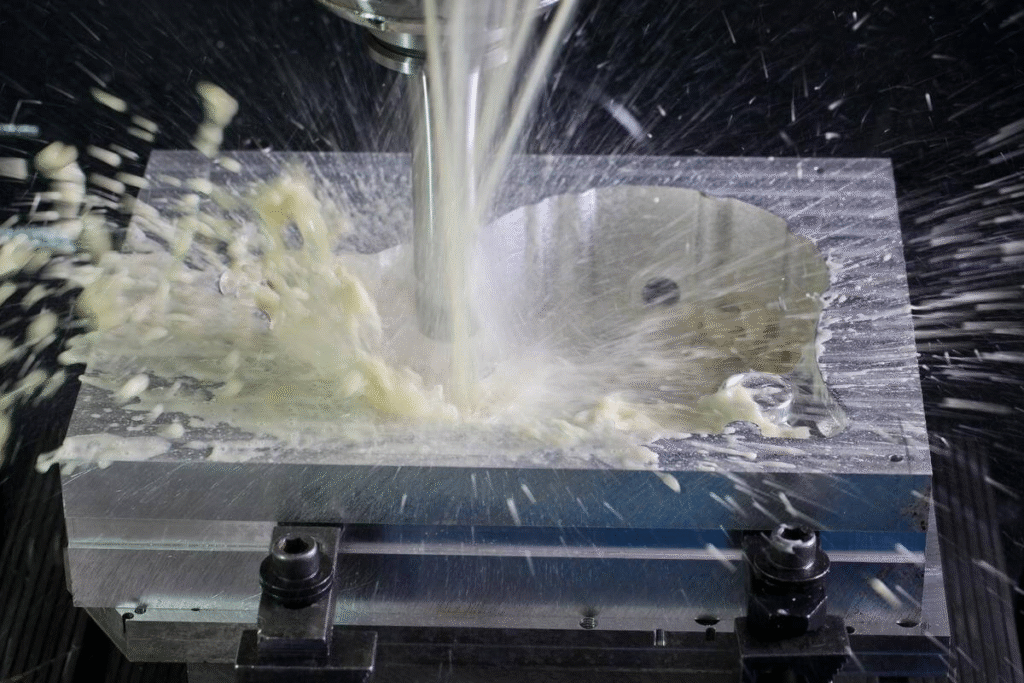

Flood Cooling

Flood cooling is the most common method in CNC machining, where a large volume of fluid is continuously directed onto the cutting zone. This approach is particularly effective for dissipating heat and flushing chips from deep or enclosed cutting areas.

Application of the cutting fluid by flooding over the tool-workpiece

Advantages:

- Maintains stable temperature across the tool and workpiece.

- Ensures efficient chip removal and a cleaner surface finish.

- Reduces tool wear by providing consistent lubrication under heavy loads.

Limitations:

- High fluid consumption and maintenance costs.

- Environmental and disposal concerns due to large waste volumes.

- Potential mist formation that affects operator health and visibility.

Flood cooling works best in continuous operations involving hard materials or long tool engagement times, where maximum cooling is necessary to prevent tool failure.

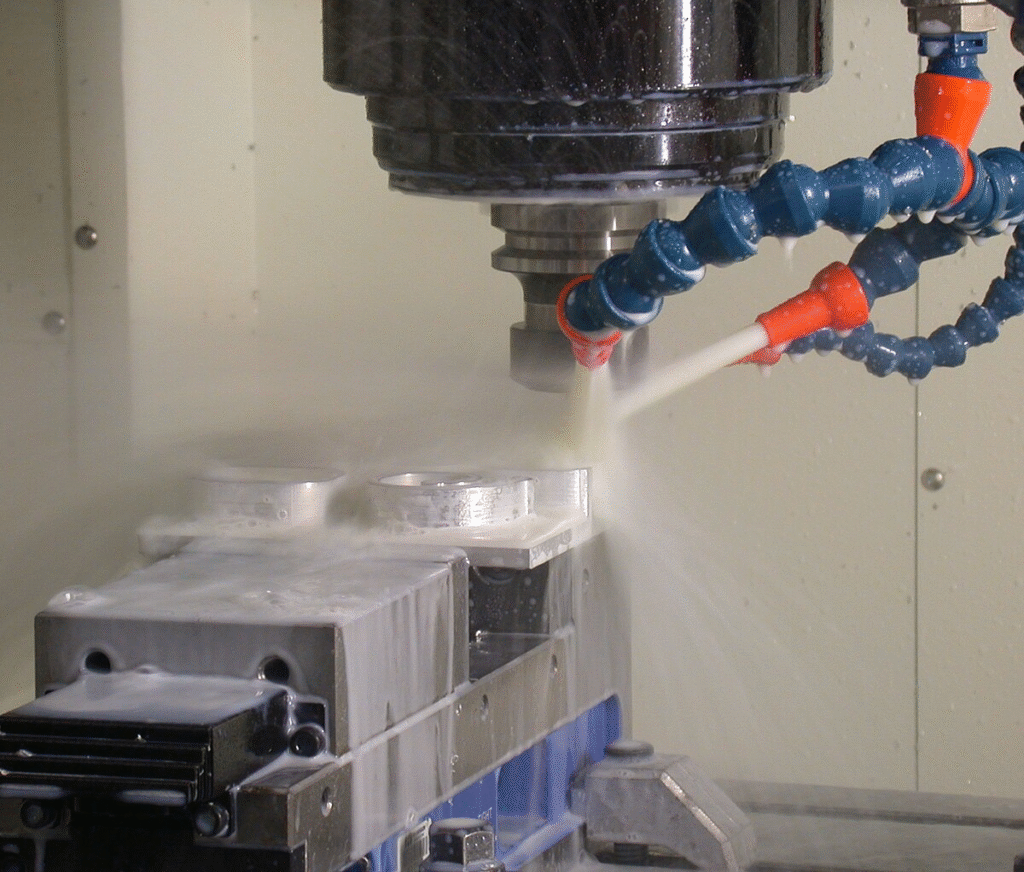

Minimum Quantity Lubrication (MQL)

MQL is an advanced lubrication method that delivers a small amount of fluid in aerosol form directly to the cutting interface. Instead of cooling through bulk fluid flow, MQL relies on precision lubrication that minimizes friction and heat generation.

How MQL Works: Compressed air carries a fine mist of lubricant to the tool–chip interface. The fluid forms a thin boundary layer that reduces contact temperature and cutting force.

Benefits:

- Significantly lower fluid usage and a cleaner working environment.

- Reduced waste handling and improved operator safety.

- Extended tool life in materials like aluminum, brass, and low-alloy steel due to targeted lubrication.

Limitations:

- Less effective in heavy-duty roughing or deep-cut operations that require strong cooling.

- May lead to thermal accumulation in high-speed steel cutting tools or during long-duration machining.

MQL is most suitable for precision or semi-finishing processes where moderate cooling and clean chip evacuation are sufficient.

Dry Machining

Dry machining eliminates cutting fluids entirely, relying on optimized tool materials, coatings, and cutting parameters to manage heat and friction. It is increasingly used in eco-conscious manufacturing and automated environments.

When Dry Machining is Appropriate:

- When materials produce short, easily manageable chips, such as cast iron.

- When tool coatings like TiAlN or DLC provide adequate heat resistance.

- When surface finish requirements are moderate and secondary finishing is acceptable.

Benefits:

- Eliminates coolant costs and waste disposal issues.

- Improves environmental sustainability and operator safety.

- Reduces corrosion and fluid contamination risks on machines.

Limitations:

- Higher cutting temperatures can degrade tool coatings and accuracy.

- Surface quality may decline without proper parameter control.

- Thermal expansion can affect tight tolerances in precision machining.

Dry machining is effective when process stability and material properties allow temperature control through cutting speed and tool geometry adjustments.

Performance Comparison for Key Materials

The optimal cooling method varies with material type due to differences in heat conductivity, hardness, and chip behavior.

- Steel: Flood cooling provides the best balance of heat control and surface finish. MQL can work for mild steel with coated carbide tools, while dry machining often leads to excessive wear.

- Aluminum: MQL offers excellent performance because of aluminum’s high thermal conductivity and tendency to adhere to tools. Flood cooling is useful for deep-pocket operations where chip evacuation is critical.

- Titanium: Flood cooling is almost mandatory due to titanium’s poor heat conductivity and high cutting temperature. MQL and dry machining may cause tool failure from rapid edge softening.

- Superalloys: Require high-pressure flood systems to maintain tool life and dimensional control. MQL or dry conditions are rarely suitable for these tough materials.

Each method has its niche, and the best results are achieved when the cooling strategy aligns with material behavior, cutting conditions, and production goals.

Inspection Methods for Cutting Fluid Quality

Cutting fluids gradually degrade during operation due to heat, chip contamination, bacterial growth, and dilution. As fluid quality declines, its cooling, lubricating, and corrosion-preventing properties weaken, directly affecting machining accuracy and surface finish. Regular inspection ensures that the fluid maintains the correct chemical balance and physical condition. Monitoring these parameters also helps prevent costly downtime caused by tool damage or part rejection.

In high-precision environments, even slight variations in pH, concentration, or cleanliness can lead to surface inconsistencies or corrosion on machined parts. A well-structured inspection routine keeps the machining process predictable and extends the usable life of both the fluid and the equipment.

Key Parameters to Monitor

Several parameters determine the performance of cutting fluids and should be measured consistently. These indicators reflect the fluid’s chemical stability and mechanical effectiveness.

- Concentration: Determines the balance between cooling and lubrication. Low concentration reduces protection and increases tool wear, while overly rich mixtures cause residue buildup. Regular refractometer checks help maintain the correct ratio.

- pH Level: Indicates fluid alkalinity or acidity. A pH between 8 and 9 is generally ideal. A drop in pH suggests bacterial growth or chemical degradation, while a high pH may corrode machine components.

- Bacteria and Fungus Count: Microbial contamination reduces fluid performance and produces unpleasant odors. Test kits or dip slides help detect growth early, allowing for timely biocide treatment.

- Tramp Oil Level: Oil that leaks from machine hydraulics or spindles can form a surface film, blocking oxygen and encouraging bacterial growth. Skimmers or absorbent pads should be used to remove it.

- Visual Clarity and Odor: Cloudiness or foul smell indicates contamination, oxidation, or excessive fines in the fluid. Visual inspection remains a simple yet valuable quality check.

Consistent tracking of these parameters maintains stability across long production runs and prevents unplanned fluid replacement.

Inspection Tools and Testing Techniques

Monitoring fluid condition requires simple but reliable instruments. Using these tools regularly provides early warning signs of degradation.

- Refractometer: Measures fluid concentration by analyzing light refraction through a small sample. Readings are compared with calibration data to ensure correct dilution.

- pH Meter or Test Strips: Used to verify acidity levels. A sudden pH change often indicates contamination or biological activity that must be corrected immediately.

- Microbial Test Kits: Detect bacterial or fungal presence within 24 to 48 hours. Early identification helps avoid fluid spoilage and unpleasant odors in the workshop.

- Filtration and Oil-Removal Inspection: Filters and skimmers should be checked for clogging or ineffective operation. A blocked filter can allow fine debris to recirculate, causing abrasion and affecting tool performance.

Routine testing using these tools provides measurable data for maintenance decisions and fluid life optimization.

Recommended Monitoring Frequency and Records

The frequency of inspection depends on production volume and machine usage. High-speed or multi-shift operations require closer monitoring than occasional machining tasks.

- Daily: Check fluid level, appearance, and odor. Clean skimmers and ensure no foaming or excessive residue.

- Weekly: Measure concentration and pH, and record values for trend analysis. Inspect filtration systems and clean sumps if necessary.

- Monthly: Conduct bacterial tests and review historical data to predict when fluid replacement or treatment will be needed.

Maintaining accurate records helps identify gradual deterioration and supports preventive action before machining quality declines.

When to Replenish vs. Replace

The decision between replenishing and replacing a fluid depends on inspection results and contamination levels.

- Replenish: If concentration or pH deviates slightly from specifications, adjustments with clean concentrate or water can restore balance. Filtration and aeration may also revive mildly degraded fluids.

- Replace: When microbial growth, tramp oil, or metal fines exceed acceptable limits, full replacement is required. At this stage, cleaning the sump and lines ensures the new batch performs optimally.

A disciplined inspection program not only maintains fluid quality but also ensures consistent part finish, extended tool life, and improved shop hygiene.

Conclusion

Cutting fluids remain an indispensable part of CNC machining, directly influencing surface integrity, dimensional accuracy, and tool longevity. Their ability to cool, lubricate, and protect both the tool and workpiece ensures that machining operations run efficiently and consistently. Proper fluid selection, concentration control, and delivery methods help achieve cleaner cuts, smoother finishes, and longer tool life while maintaining tight tolerances. Neglecting these factors can quickly lead to increased wear, poor surface quality, and higher production costs.

Equally important is the maintenance and inspection of cutting fluids throughout their service life. Monitoring key parameters such as pH, concentration, and contamination ensures that the fluid continues to perform as intended. By integrating structured inspection routines, sustainable application methods like MQL, and responsible fluid management, manufacturers can reduce waste and operational costs while protecting both equipment and the environment. Ultimately, consistent fluid care is not only a technical requirement but also a key contributor to efficient, sustainable, and high-quality CNC machining.