Precision machining is a procedure for accurately and precisely creating and shaping objects. Counterbore holes are one of the tools and methods utilized to get this level of accuracy. Counterbore holes are used in several applications across numerous sectors and are essential to precise machining. Counterbore holes are a crucial component of precision machining and have a number of benefits.

In this blog post, we shall examine the function, risk, and solution of counterbore holes in precision machining in detail. So, let's get started.

What is Counterbore?

Counterbore holes have a flat bottom that is larger than the hole's openings and is cylindrical in shape. These holes are employed to make a flat surface perpendicular to the hole's axis at the bottom of the hole. Counterbore holes can be utilized to make a site for a bearing or bushing in addition to creating a seating surface for a bolt head or nut.

It is intended to enable the bolt or screw head to be recessed below the outer layers of the product, creating a level and uniform surface. Drill bits, end mills, and specialized counterbore cutters are just a few of the instruments that can be used to make counterbore holes. The size of the bolt or screw head that the counterbore hole is intended to fit will determine the size of the hole.

Basically counterbore holes are designed to assist in distributing the weight more equally and avoiding the bolt or screw head from sinking into the material. As a result, The strength and stability of the joint may be enhanced.

There are some other similar types of holes, such as counter drill holes and Countersink holes in this blog we will discuss ahead. So, let’s move ahead.

How Significant Are Counterbore Holes in Machining?

The ability to precisely locate the object being machined is one of the main benefits of using counterbore holes in precision machining. A smooth, perpendicular surface can be made at the bottom of the hole to help locate the part being machined accurately and uniformly. This is crucial for applications where precise positioning of the item is required, such as aerospace or medical devices.

Counterbore holes may additionally be utilized to join two components together more firmly and securely. The broader flat surface at the bottom of the hole offers additional support than a typical through-hole when a bolt or screw is inserted into it. In cases where safety is an issue, this can help to prevent the bolt or screw from gradually becoming looser.

Utilizing counterbore holes to conceal the head of a bolt or screw results in a more visually appealing appearance, which is another benefit. This is especially crucial in fields like consumer electronics and automotive applications, where aesthetics play a big role.

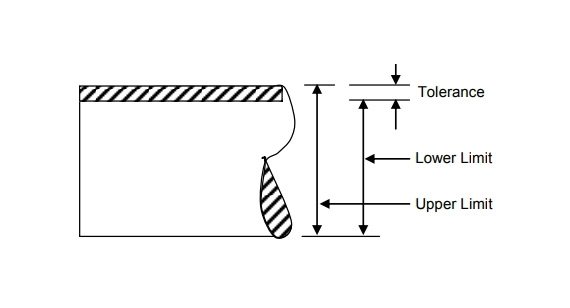

The dimensions and placement of the counterbore hole are crucial in precision machining. To guarantee that the bolt or screw will fit firmly and securely, the size of the counterbore hole must be properly measured. The proper location of the counterbore hole is also necessary to ensure that the part being machined is positioned accurately and consistently.

Counterbore vs Countersink Hole

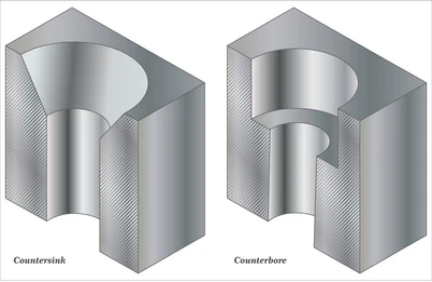

Counterbore and countersink are two different styles of holes drilled into materials, typically metals, to enable the insertion of screws or bolts to smooth the surface.

A counterbore is a cylindrical depression, usually larger and deeper than the screw or bolt head. It is employed when the screw or bolt's head requires to be recessed below the surface of the material. In cases where the screw or bolt will be covered by a decorative stopper or cap, a counterbore might be used.

For the screw or bolt head to have a chamfered opening, a countersink is employed to form a conical recess. This kind of hole enables the screw or bolt head to rest flush with the material's surface. A countersink is frequently utilized in applications where the material needs to be flushed or when the screw or bolt head has to be hidden.

In a nutshell, a countersink generates a tapered hole so that the screw or bolt head sits flush with the material surface, whereas a counterbore creates a broader and deeper hole.

Why Counterbore Holes are Used?

Enabling a screw, bolt, or other fastener's head to rest flush with or below the surface of the material being fastened to. This could lessen the chance of snagging, material damage, and component interference.

To give a fastener head or nut a greater bearing surface so that the load can be distributed over a broader area and the possibility of the fastener pulling through the material is diminished.

To create a recess to accommodate a cap or plug, which may be used for protection or decoration. Counterbores are used to make space for a bushing or bearing that can be used to provide support to spinning components.

To make it possible to install a threaded insert, which can offer a more reliable and long-lasting fastening option in materials that cannot directly support threads.

How is a Counterbore Made?

The head of a screw or bolt can lay flush with or below the surface of a material by having a counterbore, which is a cylindrical flat-bottomed hole that is drilled or machined into the material. A counterbore is typically created as follows:

- Choose Material: The first step is to choose the material that will be used to make the counterbore. The most widely used materials are plastic, wood, and metal.

- Select the Tool: After deciding on the material, select the appropriate tool to create the counterbore. A counterbore drill bit, a milling cutter, or a lathe are the most often utilized devices.

- Workpiece setup: After that, fix the workpiece in place so that it won't move while being cut. A clamp, a vice, or another holding fixture can be used for this.

- Drill the Hole: Drill a pilot hole into the material using the chosen tool. The required counterbore should have a little larger diameter than the pilot hole.

- Set up the machine: Create the Counterbore by enlarging the pilot hole with the same tool to the required counterbore diameter. The flat-bottomed hole will be carved by the tool, leaving a smooth surface behind. By shifting the tool's location and drilling deeper, the depth of the counterbore can be changed.

- Clean the Counterbore: After the counterbore has been made, use a deburring tool or sandpaper to smooth out any burrs or jagged edges.

- Test the Fit: Make sure the screw or bolt head fits snugly in the counterbore so that it rests flush or just beneath the material's surface.

What Tools Are Used for Counterbore Holes?

Counterboring is a machining technique that produces a stepped cylindrical hole, usually to enable a fastener head, like a screw or bolt, to lay flush with or below the surface of a material. In metalworking, woodworking, and other manufacturing applications, counterbores are frequently utilized. A variety of tools, including the following, can be used to accomplish a counterboring operation:

Counterbore Tool: A cutting tool made expressly for counterboring is a counterbore tool. Its end features a cutter to make the counterbore and a pilot to help the tool enter the hole.

Drill Bit: A counterbore tool is used to expand the initial hole that was made with a drill bit.

End Mill: A milling cutter that can be used for counterboring activities called an end mill.

Lathe: By utilizing a boring bar or a counterbore tool, a lathe can be used to drill counterbores into cylindrical objects.

CNC Machine: Counterboring activities can be carried out precisely and consistently using a computer-controlled CNC machine.

Making the Correct Tap Selection for a Counterbore Hole

There are a few things to take into account when choosing a tap for a counterbore hole in order to make the right choice:

Thread size:

The bolt or screw that will be used in the hole should have a thread size that corresponds to the tap size. By doing so, the threads will be adequately produced and will fit securely.

Material:

When choosing a tap, the material of the object should also be taken into account. A high-speed steel tap might be adequate for softer materials like aluminum or brass. It could be necessary to use a cobalt or carbide tap for tougher materials, including stainless steel.

Hole depth:

The depth of the counterbore hole will also influence the tap choice. For small holes, a shorter tap might be adequate; for larger holes, a bigger tap might be required.

Chamfer:

The tap's chamfer should also be taken into account. While a tap with a smaller chamfer may be better for more precise threading, one with a larger chamfer might be more effective for beginning threads in hard-to-reach places.

What is Counterbore Callout Symbol?

A counterbore symbol is a cylindrical hole with a flat bottom that broadens a coaxial hole(⌴), or the instrument used to make that feature.

Application of Counterbore Hole in Machining

The machining process of counterboring is frequently employed in a variety of sectors, including engineering, automotive, and aerospace. Here are a few machining scenarios where counterboring is used:

Installation of fasteners:

The main purpose of counterboring is to create a flat-bottomed hole for a fastener head. A secure and solid bond is created when the fastener head is level with the outermost layer of the material due to the counterbore hole.

Installation of Bearings:

Counterboring can also be utilized to make a bearing seat. The bearing may be simply pressed into place and will provide the necessary alignment and assistance if a flat-bottomed hole is made that is bigger in size compared to the bearing.

Making a Chamfer:

A chamfer can be made around a hole using counterboring. A chamfer is a beveled tip that offers a seamless transition between two surfaces, lowering the possibility of sharp edges that might injure someone.

Counterbore Hole magnet

Some tips to get the perfect counterbore hole

Here are some suggestions for creating the ideal counterbore hole:

Select the proper tool:

The size and depth of the required hole will determine the appropriate counterboring tool. It is crucial to pick a counterbore tool that corresponds to the hole's required size and depth.

Choose the appropriate Material:

For the counterbore tool, choose the appropriate material. The tool's material should be tough and hard enough to cut through the material without wearing out too soon.

Prior to starting the counterboring procedure, make sure the hole is centered. To serve as a guide for the counterbore tool, make a small indentation in the center of the hole with a center punch.

Use the proper speed and feed rate:

The counterbore tool's speed and feed rate are essential for obtaining a precise hole. A tool may become hot and wear rapidly at excessively high a speed or feed rate, whereas a hole of poor quality will be produced if the speed or feed rate would be low.

Maintain the tool:

To keep the counterbore tool in good shape, make sure it receives routine maintenance. After each usage, wash the tool, and replace it if it starts to seem worn or damaged.

Finally, periodically throughout the process, check the depth of the counterbore hole to make sure it corresponds to the required depth. To measure the depth precisely, use a depth gauge.

Counterbore Hole Risk and Solution

Counterbore holes have the potential to weaken the material surrounding the hole, particularly when the counterbore hole is excessively big or too deep. This may cause the material to crack or perhaps lose its structural integrity.

The size and depth of the counterbore hole should be carefully chosen depending on the material being utilized and the load that will be delivered to the fastener in order to reduce this danger. Generally speaking, the counterbore hole shouldn't be greater or wider than what's required to fit the fastener's head.

The material's precise stability surrounding the counterbore hole must be ensured as well. This can be accomplished by employing a backing plate or by enclosing the hole in more material to add support.

Ultimately, to prevent loosening or failure over time, it's critical to select high-quality fasteners which are suitable for the purpose and are put in properly. Regular checks and upkeep can aid in detecting any potential issues before they arise.

Other Types of Holes in the Machining Industry

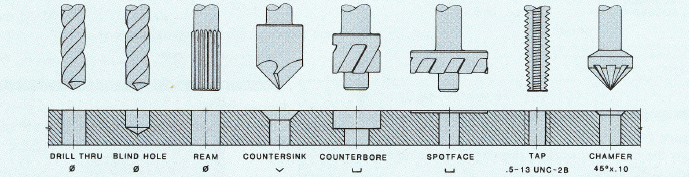

There are several sorts of holes that can be created in the machining sector utilizing different machining techniques. Here are a few instances:

Counterbore Hole:

A counterbore is a cylindrical hole with a flat bottom that enlarges the top of an already-existing hole. A bolt head or nut is frequently seated with it to ensure it lies flush with the surface of the object.

Countersink:

To enable a screw head to sit flush with the surface, a countersink is a cone-shaped hole that has been bored into a material. It is frequently used to enhance the completed product's look and lower the possibility of snagging or sticking on the screw head.

Tapered Hole:

A tapered hole is one that gradually gets smaller in diameter as it goes along. To make a snug fit for a pin or other cylindrical component, it is frequently utilized.

Blind Hole:

A hole that partially penetrates a substance is referred to as a blind hole. It is frequently employed to make a pocket into which a screw or other fastener can be threaded.

Thru-Hole:

A thru-hole is a hole that goes all the way through a substance. It is frequently employed to make a passageway for a pin, bolt, or other component.

Reamed Hole:

A hole that has been completed using a reamer, a cutting tool intended to remove a small number of substances and provide a precise diameter and surface polish, is referred to as a "reamed hole."

Drilled Hole:

The hole that has been created with a drill bit is referred to as a drilled hole. Simple holes for fasteners, electrical wires, or fluid passages are frequently made using this technique.

Conclusion:

Counterbore holes are cylindrical in shape and have a flat bottom that is larger than the hole openings. Different types of tools such as drill bits, counterbore tools, and end mills are used to create counterbore holes. Precision machining relies significantly on counterbore holes, which also provide a variety of advantages. In this blog, we discussed in detail counterbore holes' functions and how it is created.

Unfortunately, there are some risks associated with counterbore hole production. By comprehending the dangers associated with counterbore holes and implementing the necessary remedies, engineers and machinists may produce precise, reliable parts that adhere to the greatest criteria of quality and performance.