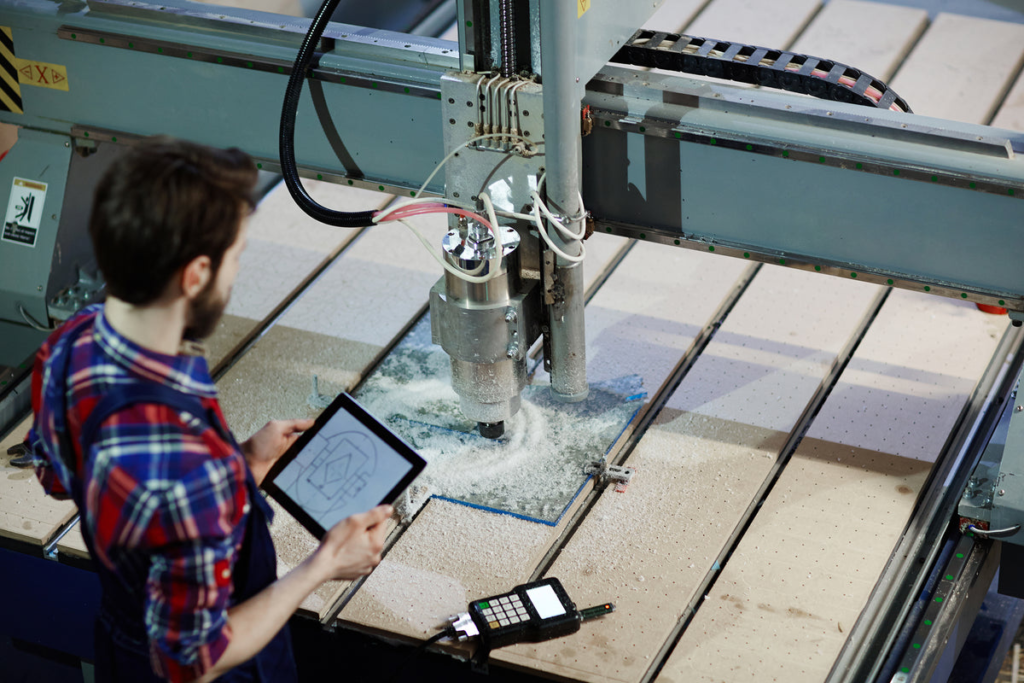

The industrial internet is revolutionizing the way how custom machining works. It’s not just about getting faster, and having more accurate outcomes; it’s also about being able to optimize every step of the process. The industrial internet enables custom machining companies to become far more efficient, gain better insight into their production process, and deliver superior results with less work and fewer resources. In this blog post, we will explore the many benefits that come with using the industrial internet in custom machining. Read on to learn how this technology can help you get the most out of your production operations.

what is the industrial internet of things?

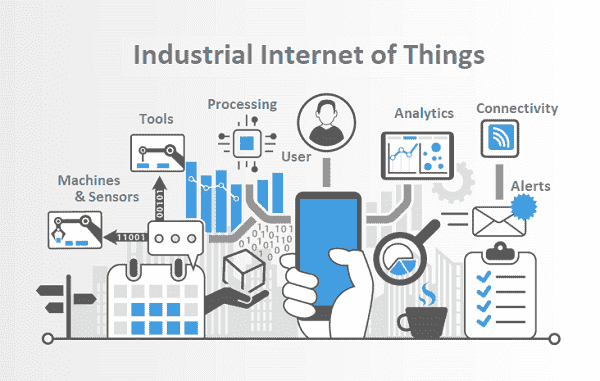

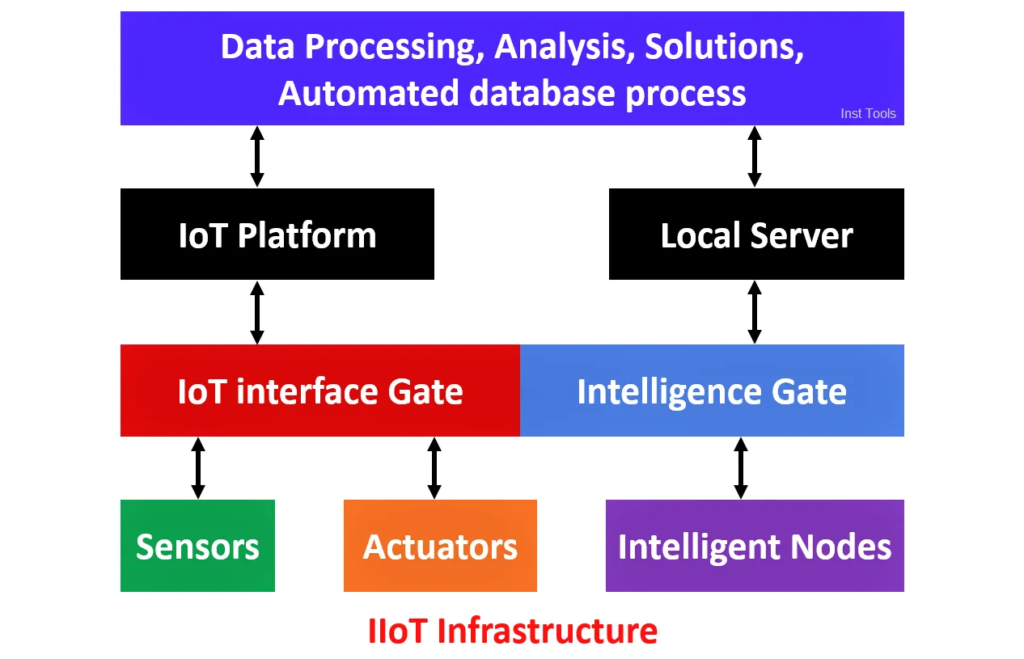

The industrial internet of things, or IIoT, is a term used to describe the network of physical objects and devices that are connected to the internet. This includes everything from factory machines to vehicles to medical devices. The IIoT has the potential to revolutionize the way we live and work, by making it possible for us to interact with the physical world in ways that were never before possible.

One of the key benefits of IIoT is that it can help us to better manage and understand complex systems. For example, consider a manufacturing plant that uses hundreds of different machines to produce products. Traditionally, each machine would need to be monitored separately, and any issues would need to be addressed one at a time. With the IIoT, all of these machines can be connected and monitored from a central location. This means that problems can be identified and fixed more quickly and that the overall efficiency of the plant can be increased.

Another benefit of the IIoT is that it can help us to make better use of data. In many cases, data collected by various devices is not used effectively because it is difficult to analyze manually. With the IIoT, this data can be collected automatically and analyzed using artificial intelligence or other methods. This analysis can then be used to improve processes or decide where resources should be allocated.

Industrial Internet of Things: Why It's Important (IIoT)

The effective use of smart sensors, transmitters, and actuators to improve industrial production and manufacturing processes is the focus of the industrial internet of things (IIoT). The Industrial Internet of Things (IIOT) employs real-time analytics and smart devices to make use of the data that "dumb old machines" have been producing in industrial settings for years. This data can be modified to maximize business process efficiency as well as used for predictive maintenance.

The industrial internet of things (IIoT) is based on the premise that smart machines are more effective than humans in collecting and analyzing data in real-time. They also communicate vital information more efficiently, correctly, and quickly, which can be leveraged to accelerate corporate choices.

Lean Manufacturing and a smooth production cycle can be easily achieved by implementing the collected data, non-uniform behavior of machines, preventive maintenance requirements, identifying the faulty part, and giving a bird's eye view of the entire mechanism. Particularly when it comes to machine shop performance, CNC machine parts exhibit incredible behavior in terms of temperature, performance, vibration, and other technical data. Storing this data using an IIOT mechanism and incorporating it into the production process can have a significant impact on the manufacturer's bottom line.

What benefits IoT Can bring to the industry?

Some possible benefits of the coupling of CNC machining with IIoT are particularly notable as a potential driving force for the growth of CNC machining:

The advantages of IoT in Industry Process Monitoring & Quality Assurance Make Simple

Another advantage of IoT in the industry is that it can alter based on changes in weather or temperature, humidity, and other conditions that may affect how equipment work. This is especially important for delicate activities, where machines can detect and compensate for changes. This could include talking with the thermostat or air conditioning to maintain a sufficient level of warmth in the workplace.

In terms of process optimization, devices connected to the Industrial Internet can communicate with M2M systems. This allows devices in the same workflow to share information regarding anomalies or variances in a product on the assembly line or during the machining process. As a result, they can modify to compensate for weaknesses in one or both areas. This improved level of communication throughout segments of the production workflow can increase end-product quality while also ensuring uniformity between units.

Robotic Labor

It's crucial to note that, although this is a significant aspect that may be the subject of a separate discussion, the IoT has the potential to make it possible for other robotic systems to collaborate with CNC machining. Take the straightforward task of sorting things once they are produced as an example. Now that the Internet of Things (IoT) enables various machines and systems to connect, we can also observe that this classification and organization are fully automated. Even though this is still largely thought of as human work. This can lower labor expenses and stop accidents at the workplace.

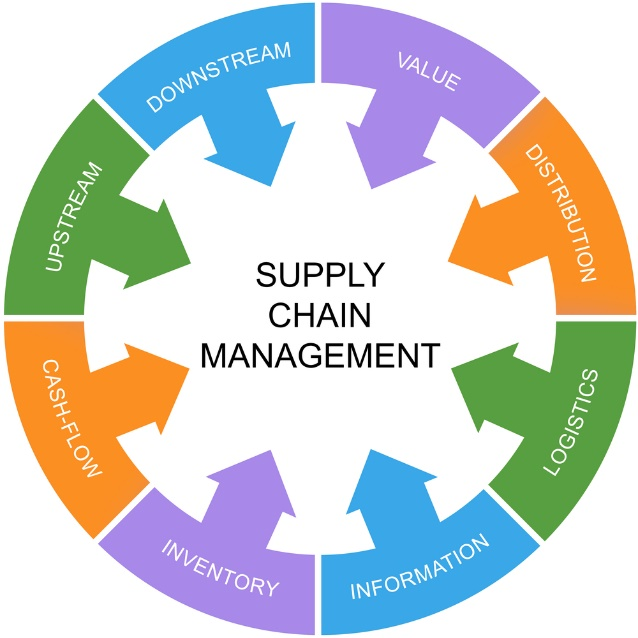

Consolidated Supply Chain

The entire supply chain now functions more efficiently thanks to IIoT. Key staff members can access inventory records and product information using nearly any Internet-enabled device because to the system's interconnectedness. Sensors make it simple and quick to track the products that are being carried. These sensors can display data about their present location, surroundings, and even physical ailments.

Boost Sustainability :

IIoT improved factory sustainability. IIoT makes cheaper, greener hardware, data analysis, and power consumption control solutions possible. IIoT-enabled robotic production saves money. By automating tedious production tasks, manufacturing businesses may focus on cultivating top talent and minimize their concerns about regular people. IIoT devices' enhanced sustainability and energy efficiency may save even more money.

Manufacturers might help machine shops remotely by tracking their assets without having to look at the machine or request an inspection from the owner. As a result, the organization can provide input and handle difficulties much more quickly. Furthermore, machine shops could profit greatly from an internet machine shop by requiring fewer maintenance inspections of their own.

Heighten competition :

IIoT increases a company's competitiveness. In a few years, this may be a commercial standard. Early adopters of the new strategy and IIoT's benefits will have an advantage over their strongest competitors. A recent study found that these infrastructure formation stages benefit the most significant and first IIoT integrators.

CNC machine tools are good beginning points since they use computers. As shown, productivity, security, and leaner, more proactive production is affected. It's many advantages are astounding. As technology improves, everyone may guess what changes will be made and their benefits.

Given these benefits and their positive impact on connected sectors, we strongly believe that the IIoT will help improve CNC machining and other new manufacturing processes.

Reduced manual labor and improved safety

Its benefits in the industry include less manual labor and improved safety.

One of the most significant advantages of IoT in business is that it reduces the amount of work necessary at any given time. As a result, businesses can rely on data from an internet machine shop within the IoT process to carry the load. This allows employees to focus on other tasks.

Similarly, machines may keep track of their own status. They can forewarn employees about overheating, mechanical issues, or future power outages. These can reduce occupational injuries and make repairs less reliant on guesswork. Another advantage of regular monitoring is that it reduces workplace dangers. This is due to the absence of physical workers because monitoring is done remotely. As a result, with fewer personnel present, there are fewer possible workplace safety infractions.

Many organizations are already developing repair and maintenance robots based on IoT concepts. Using pre-programmed protocols, these robots can identify and manage other devices. This would further eliminate the need for human intervention and assure immediate fixes in most cases. These IoT solutions would be beneficial.

Because technology is continually evolving, these functions are simply scraping the surface of what is conceivable. However, the convergence of IIOT's growth, CNC machining, and 3D printing is casting light on a variety of workflow improvements and production modalities. Furthermore, these technologies are anticipated to merge soon, providing new opportunities for machine shops around the world.

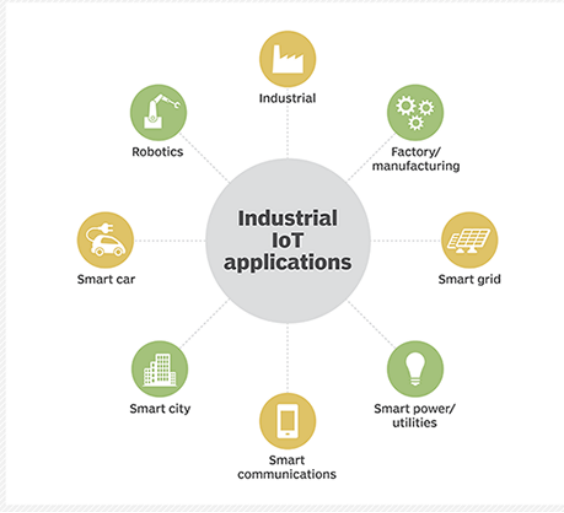

Applications of industrial IoT :

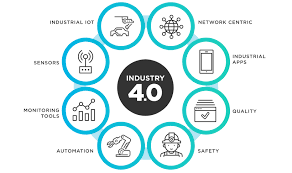

IIoT technology has several uses in contemporary industry sectors due to its real-time monitoring and reporting capabilities, especially when combined with AI-powered analytics, automated procedures, and a best-in-class ERP.

Smart Manufacturing:

Companies collect information from the worldwide market, media trends, and customer feedback. AI-powered systems can combine this information with other pertinent data to help with product creation and quality assurance. Such insights can be used to automate an IIoT network of machines and robotics to optimize product manufacturing in smart factories.

Resilient supply chains

IIoT networks give supply chain managers access to information such as the location of their items, the suppliers that have them, and the quantity on hand. IIoT machines and devices can also be instantly designed to adjust to real-time events and disturbances, giving organizations built-in contingency planning and a competitive edge.

Agriculture

Modern agriculture combines IoT technologies for precision farming that distributes water and other resources as needed. Smart gadgets and sensors give facility managers unprecedented operational data to reduce costs, extend infrastructure life, and boost energy efficiency. IIoT sensors monitor and regulate zone heating in real time. In older buildings, sensors can detect vibrations, cracks, wetness, and structural issues. Early leak detection prevents flooding.

Conclusion

People, processes, and technology that communicate with smart sensors and actuators are all part of the Industrial Internet of Things (IoT). Industrial automation is the new way of manufacturing, it gives marvelous results in production, maintenance, and product durability. Implementing IIOT will reduce the burden of the manufacturer and increase bulk production with precise results.