Stainless steel is a popular material for a wide range of industrial and manufacturing applications. It’s all due to its properties like high strength, durability, toughness, surface hardness, and corrosion resistance. It is widely used in the production of medical devices, automotive parts, spacecraft, and a diverse range of industrial applications. There are several ways to manufacture products from stainless steel material, including CNC machining and casting.

But here’s a question rises, which manufacturing technique is ideal for Stainless steel manufacturing? In industrial applications both methods have their own set of benefits and drawbacks, CNC machining has some key advantages over casting, in high precision, tight tolerance, bulk production, and ease of complex designing, which makes it a superior choice in certain situations. In this article, we will go over all the arguments that answer this question. But, before we get into that, it’s important to understand how both techniques work.

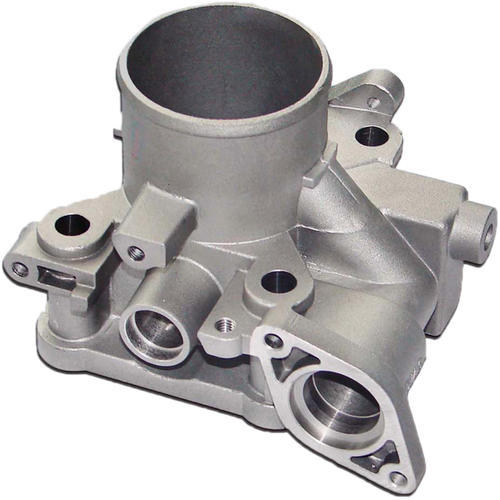

Stainless Steel Casting: How it Works?

Stainless steel casting is a process in which stainless steel is melted and cast into a specific shape or form. The procedure entails pouring molten metal into a mold and allowing it to cool and solidify into the desired shape. The mold is usually made of a material that can withstand high temperatures and is resistant to corrosion, such as ceramic or graphite. After the metal has cooled and solidified, the mold is broken or cut open to reveal the finished part.

The casting is then cleaned and polished to remove any excess material or imperfections. Finally, the casting is inspected for quality and any necessary machining is performed to achieve the desired tolerances and finish. Engine heads, bus accelerators, turbine blades, and train wheels are a few examples of frequently cast components. Most of the industry, including the car manufacturer, aerospace industry, and medical device sectors, use cast parts.

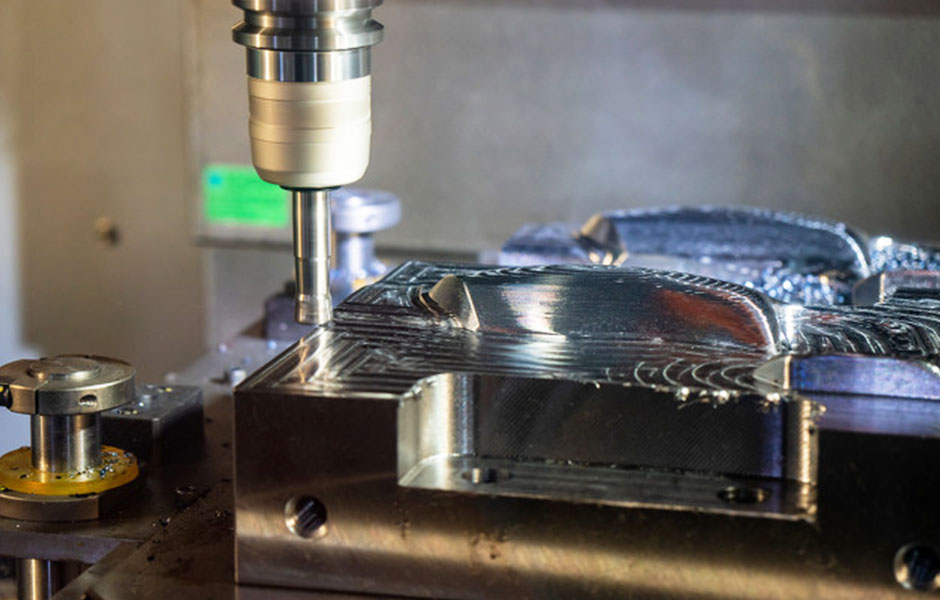

CNC Machining: How it works?

CNC (computer numerical control) machining is a manufacturing process in which computer software is used to control the movement and operation of machine tools, such as lathes and mills. The Process starts with the development of a 3-D model of the desired product using specific engineering softwares like CAD- CAM, solid works, and PTC Creo. This 3-D model is then converted to a G-code computer language, which is understandable by the CNC machine’s control unit. Once the Coded program is saved, the cutting tool follows the encoded command. The machine may make multiple passes over the workpiece, removing material in layers until the final shape is achieved.

The machined part is then inspected to ensure that it meets the required tolerances and specifications. Any necessary touch-ups or finishing processes are performed, and the part is cleaned and ready for shipment. The machining process is typically automated, with the CNC equipment being controlled by the CAM software. However, a skilled operator is still needed to set up the equipment and troubleshoot any problems that may arise during the machining process. Top of FormCNC machining is used to create metal laptop casings, the car industry, the accessory of cell phones and aerospace parts, holding setups, and casting setups.

Factors that make Stainless Steel CNC Machining Superior to Stainless steel Casting:

Overall, CNC machining can offer several advantages over stainless steel casting, particularly for applications that require high levels of precision, speed, or versatility. Several factors can make CNC machining superior to stainless steel casting for certain applications including:

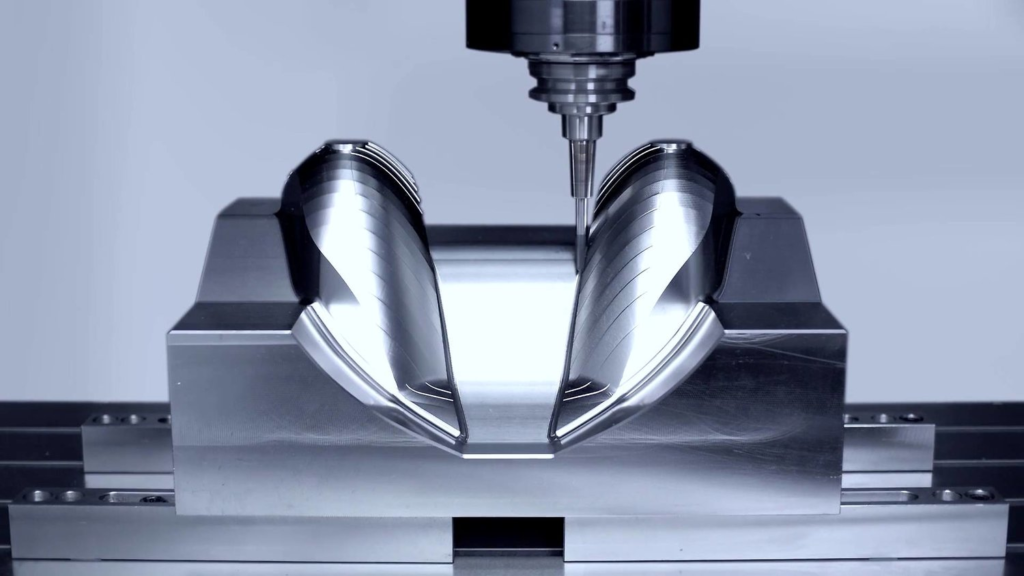

Greater design flexibility:

The geometry of the part should be considered before selecting the best production method. CNC machining allows great design flexibility during the production process, as the computer program can be quickly modified. CNC machines can produce complex shapes and geometries, particularly undercuts and grooves.

However, the casting makes it more challenging to achieve some features. More challenging elements like undercuts or interior details need intricate molds with inserts and cores. Cast pieces need a draught angle for every feature, and sharp edges or corners are also not suited for casting. Because these geometries are challenging to fill and settle down properly during the process of casting, large or unusually shaped components with thick walls are also better suited to CNC machining.

Machining Repeatability:

In manufacturing, repeatability is crucial, the process of casting creates repeatable pieces. Every part is produced identically once the mold and process are optimized. For precisely cast, the usual range is.002″ per 1 and 0.01″ to 1″.

CNC metal machining has a lot higher tolerance than that casting and is a highly repeatable, precise operation. A fair estimate is 0.025mm (0.001″) for ordinary metal machining. Parts may be produced using precision machining with tolerances as fine as 0.0002 inches. Which makes CNC machining whey superior.

Accuracy and Precision:

CNC machining allows for high levels of precision and accuracy in the finished product. The cutting tool is operated by the G-code and follows the pattern with tight tolerance and precision. CNC machining can produce parts with a much smoother surface finish compared to casting. CNC machining allows precise control over the machining process, while casting often results in a rough surface finish and dimensional errors are significant in it.

Temperature management:

Because of its high melting temperature, stainless steel is more difficult to melt. The melting temperatures of stainless steel can range from 1375°C for grade 316 steel to 1510°C for grade 430 steel. Casting at this elevated temperature is difficult to manage and whey costly.

However, the processing of parts in CNC is a bit easy as the cutting temperature is manageable with cutting tools and coolant. The cutting of stainless-steel material with help of carbide and HSS is easy and manageable at room temperature.

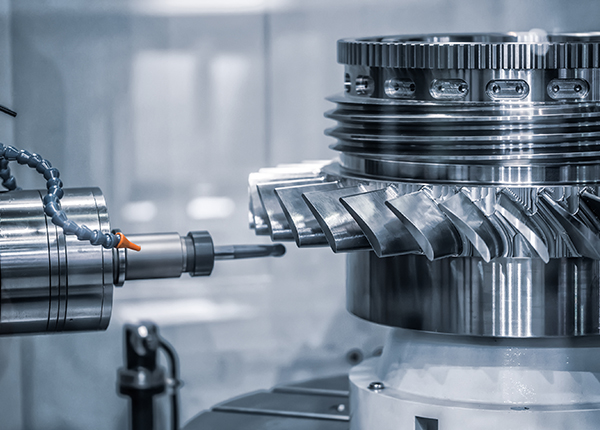

Complex geometries and Surface finishing:

CNC machining can be used to produce parts with complex geometry and intricate details that may be difficult or impossible to achieve through casting.

Casting for intricate and complex parts may result in dimensional errors and rough surface finishing. However, through CNC machining we can achieve consistent feed, appropriate tooling, tight tolerance, and accurate precision.

CNC machining allows for precise control over the surface finish, as the machining process can produce a wide range of finishes from rough to very smooth, depending on the tooling and processes used. Cast parts may require additional finishing steps to achieve the desired surface finish.

For Prototyping:

If you are in the prototype stage of the part process, casting is not a good option. You will have to change the mold dimensions every time your design changes, which increases the process time and costs. In that way, a lot of money will be spent on a prototype die cast.

With the greater flexibility of altering a CNC metal machining process, CNC machining is a preferable option for prototyping. Instead of building a new mold or attempting to alter an existing mold when the concept is still in development, you just have to update the model and start over using the CAM application.

Material Options and versatility:

Casting is typically restricted to metals and alloys that can be cast, whereas CNC machining can be used with a wide variety of materials, including stainless steel, metals, plastics, aluminum, brass, and composites. CNC machining can produce parts with a high-quality surface finish, as the cutting tools can produce smooth and precise surfaces with no need for post-processing requirements.

Fast manufacturing Cycle:

In some cases, CNC machining is generally more expensive compared to casting, due to the high cost of the machining equipment and the skilled labor required to operate it. However, for complex parts or low-volume production runs, the higher precision and accuracy of CNC-machined parts can justify the higher cost in some applications.

The lead time for the process of casting is normally a couple of days. Once the mold is prepared, the casting procedure itself proceeds quite quickly, which makes it suitable for making large quantities of components. But it takes some time to develop and machine a mold. Despite the fact that certain casting techniques employ disposable molds, the mold still has to pass assurance tests for quality and maintenance. Die casting, on the other hand, utilizes a long-lasting mold, thus as the quantity of parts grows, and cost of the part reduces and also the time.

On the other hand, with the higher manufacturing speed offered by CNC machining, small batches of parts may be finished more quickly. To start creating components is a CNC machine, a CAD model, and a CAM application, there is no need to wait for the mold to be made.

Casting or Machining Whom to choose?

Overall, CNC machining is a superior choice for the production of stainless steel parts in certain situations due to its precision, flexibility, and ability to produce small batch sizes and high-quality surface finishes. However, the choice of manufacturing technique always depends upon your design, production quality and lead time, Surface finishing required, and project cost. So, one should consider all key, parameters, before deciding, as an accurate decision leads you toward smooth and lean manufacturing. Expert advice is something that is always needed, if you have a project, in your mind and confuse about how to convert your idea to reality, you can consult our experienced staff for a piece of expert advice.

CNC machining is typically the better choice for producing complex and precise parts or for companies that need the flexibility to produce small batch sizes or prototypes. However, there are some cases where stainless steel casting may be a better choice, such as when producing very large parts or when the quantity of parts needed is very high. In these cases, the cost savings of casting may outweigh the benefits of CNC machining.