Searching for a trustworthy and effective means to construct your sailboat?

Look no more!

CNC machining is a cutting-edge machining approach that can aid you in developing a high-performance sailboat in less time and effort.

Let's discover the utilization of CNC machining in sailboat building and discover how it can be beneficial for you.

Benefits of CNC Machining in Sailboat Building

CNC machining provides various advantages for sailboat building. Automation ensures improved accuracy and quality of production. Plus, the precision through CNC is far greater than manual processes. What's more, the speed of production is often much faster.

Precise dimensions mean no human error when producing parts. Hull shape or performance won't be compromised due to faulty construction materials or techniques. Cuts are made quickly, leading to shorter production periods with full sheet construction or sew-and-glue applications.

CNC machining also offers safety benefits compared to manual operations. Operators can run multiple machines simultaneously while reducing personnel and skilled labor costs. Complex cutting tasks become much simpler with the computer-controlled operation. This reduces personnel costs without compromising performance benefits from varnishing or buffing operations.

Challenges of CNC Machining in Sailboat Buildings

CNC machining is the use of computers for controlling machine tools like lathes, mills, and routers. It has revolutionized boat building, offering more precise, repeatable cuts and shapes. But CNC also presents challenges.

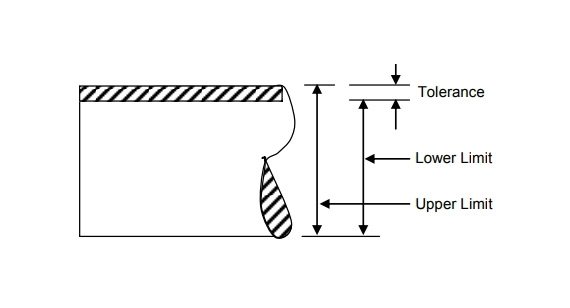

Material selection and design optimization are a big challenge since CNC machines have limited tolerance. Tight tolerances increase weight, so designers must be careful not to add too much pressure to stressed sections of the hulls and components.

Plus, aluminum is tougher to work with on CNC machines. It can cause thermal drift, resulting in variations in depth or width. This weakens parts. Modern machines provide real-time feedback to help, but an expert operator must monitor for accuracy, especially for complex sailboat components. Imperfections can cause wind drafts during races or even leaks on long trips.

Types of CNC Machines Used in Sailboat Buildings

CNC machining is the go-to for sailboat building. It's new, but it has lots of advantages. Accuracy, precision, and control over the whole fabrication process are improved.

Milling machines, router tables, laser cutters, and plasma cutters are some of the types of CNC machines used. They provide cost-effective production solutions.

Milling machines use rotating cutting tools to shape faces, slots, holes, and contours. Routers use spinning router bits and are great for masts and spars. Laser cutters can make precise cuts up to 1/4 inch thick, and plasma cutters use electric arcs to cut thicker steel.

Design Considerations for CNC Machined Sailboats

CNC machining for sailboat building is an awesome way to boost accuracy and productivity. Before starting any project, it's important to think about the boat design and how it should work with the technology.

When creating a sailboat with CNC machining, designing for strength and weight is essential. Strength should be available everywhere, particularly in stress or vibration-prone areas. Weight matters, too - lighter boats go faster on the water.

Measuring and tolerances must be taken into account when designing a sailboat for CNC machining. Precision helps parts fit together well and quickly, while too much precision means double-checking and delays.

Aesthetics are key! Balancing materials and surfaces affect performance and make the whole thing look good. 3D modeling software can help visualize designs before production, which is really useful.

CNC Machining Technologies for Sailboat Building

CNC machining technology has improved sailboat construction with precision, speed, and consistency. CNC machining in sailboat construction technologies includes:

5-Axis CNC Machining

5-axis CNC machining can create complex shapes with five axes of movement. This technology creates molds for hulls, decks, stringers, and bulkheads.

Waterjet Cutting

Waterjet cutters can cut metal, plastic, and composites. This technology cuts complicated forms and patterns on inner and exterior pieces like rudders and keels.

CNC Routing

CNC routing removes material by rotating the cutting tool. Wooden cockpit flooring and storage cupboards are often cut with complex designs using this process.

CNC Milling

CNC milling cuts material with a spinning tool. Keel bolts and winches employ this technology to generate complex forms and geometries.

3D Printing

3D printing creates three-dimensional things layer-by-layer from digital files. This method is used to make prototypes and small batches of deck hardware.

Laser Cutting

Laser cutting employs a powerful laser beam to cut metal, plastic, and wood. Laser cutting creates precise mast parts and bulkheads for sailboats. Sailboat parts with elaborate designs and patterns are laser cut.

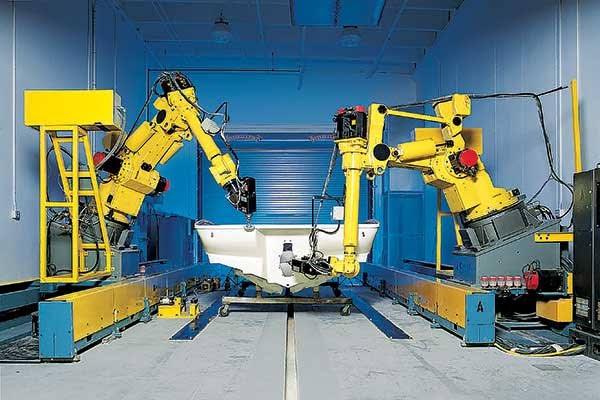

Robotic Machining

CNC robotic machining employs robots to create sailboats. Robotic machining produces accurate, consistent sailboat hulls and decks. Robots boost productivity and accuracy.

Future of CNC Machining in Sailboat Buildings

As long as it continues to provide boat builders with so many advantages, CNC machining in sailboat construction has a bright future. As technology improves, CNC machines are becoming more complex and flexible. This lets them work more precisely, quickly, and efficiently.

The utilization of high-tech materials like carbon fiber composites, which are increasingly popular for sailboat construction, is an area where CNC machining is projected to make considerable strides. These materials are robust, lightweight, and long-lasting, and CNC machines can precisely generate complicated shapes and structures, allowing boat builders to make sailboats that are more effective and perform better.

Additionally, it is expected that the incorporation of machine learning and artificial intelligence technology into CNC machines would significantly improve their capacity for sailboat construction. By learning from past operations and adapting to new ones, these technologies can boost efficiency, minimize errors, and optimize the machining process.

The utilization of additive manufacturing processes, such as 3D printing, which can quickly and cheaply make intricate and complicated parts, is another area of development for CNC machining.

Although CNC machining has advanced, it's vital to remember that traditional boat-building methods will always have a place in the production of sailboats. While traditional methods will still be used, CNC machining will complement them and give sailboat builders more alternatives for producing high-quality, personalized vessels.

In conclusion, the use of CNC machining in the construction of sailboats has a promising future. As technology advances, it will be possible to develop better, more innovative, and more efficient sailboats.

Frequently Asked Questions (FAQs)

What are the limitations of using CNC machines in sailboat buildings?

CNC machining has some drawbacks in sailboat building. CNC machines are expensive to buy and install. CNC machines are not good at making curved or asymmetrical designs, which conventional boatbuilding methods can do better. Some boat builders find CNC machines difficult to use since they require expert operators to program and run them. Finally, CNC machines may manufacture parts that lack the creativity and artistry of traditional boatbuilding.

How has CNC machining technology revolutionized sailboat production?

CNC machining has changed how sailboats are made by making it easier for builders to make complicated shapes and structures more accurately and with less waste. It has also made using more advanced materials like carbon fiber composites possible. A wider variety of sailboats may be built because of the increased efficiency and lower cost of production made possible by CNC machines.

Can CNC machining replace traditional boatbuilding techniques?

CNC machining has many benefits, but sailboat builders will still use hand shaping and woodworking. These approaches offer a unique beauty and skill that CNC machines cannot match. CNC machining will supplement traditional methods to help boat builders produce high-quality, personalized yachts.

How does CNC machining help in producing customized sailboats?

Boat builders can rapidly and accurately make complex and precise pieces with CNC machining. Boat builders can make custom designs using their molds and blueprints for boat part fabrication. CNC equipment can make one-off boats and limited manufacturing runs.

Can CNC machining be used for sailboat repairs and maintenance?

Yes, CNC machining is a viable option for fixing sailboats since it can precisely replicate worn or broken pieces. This will ensure that the fixed piece will be a perfect fit for the boat's original design.

What types of parts can be made using CNC machining in sailboat building?

CNC machining allows for the production of a wide variety of sailboat components, such as hatch covers, bulkheads, rudder parts, and other fixtures.

How precise is CNC machining in sailboat building?

Making sure the parts of a sailboat all fit together precisely requires a level of precision that can only be achieved with CNC machining, which can attain tolerances of a few hundredths of an inch.

How does CNC machining benefit the environment in sailboat building?

CNC machining's capacity for optimizing material utilization can significantly cut down on scrap, making for greener sailboat manufacturing processes.

Conclusion

Examining CNC machining in sailboat building reveals it is a valuable asset. It provides precision, faster production, cost savings, waste reduction, and better product quality. This enables more effective and efficient designs. Safety is increased due to accuracy. Engineers and manufacturers can trust their products.

Implementing CNC machining technology in sailboat building provides superior quality vessels from precision parts and design optimization.