The complexity and connectivity of supply chains are rising in today’s globalized world. Although they make it easier for products and services to be moved efficiently, they are also prone to a variety of dangers that could have an adverse effect on organizations and operations.

Only 21% of organizations claimed to have a highly resilient supply chain network that involves strong visibility and the flexibility to move sourcing, production, and distribution operations reasonably quickly, as shown in a recent Gartner poll. Thus, with sufficient resilience, organizations can avoid risks that would otherwise have a long-term negative effect on them.

These risks comprise natural disasters, geopolitical conflicts, economic changes, cyber threats, and pandemics. It happened in recent events like the COVID-19 pandemic. Organizations must put strong risk mitigation plans into place to protect their supply chains and guarantee business continuity. This post will examine five crucial measures to reduce supply chain risk. But, before we move ahead it is necessary to know why supply chain management has worth in the industrial sector. Thus, let’s explore this in more detail here.

1. Why is Supply Chain Management Worthwhile in the Industry?

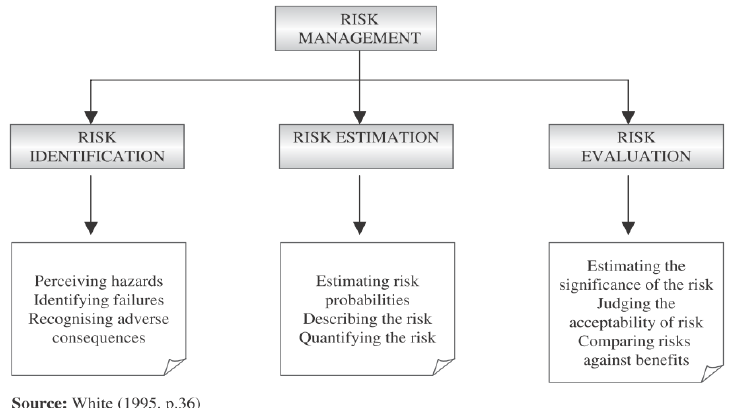

Supply chain risk management is implementing proactive measures that assist supply chain planners in locating, evaluating, and eventually mitigating the significant risks associated with supply chain interruption. There are numerous convincing reasons why supply chain management is crucial to the sector: Let me elaborate in more detail below.

A. Efficiency & Cost Reduction:

A supply chain that is well-managed may improve the flow of information, materials, and resources, increasing the effectiveness of both manufacturing and delivery. Companies can lower operational expenses and increase overall profitability by streamlining operations and reducing waste.

B. Better customer service:

A well-planned supply chain guarantees that goods arrive at customers’ locations promptly and in excellent condition. Customer satisfaction and loyalty are cultivated when demands are met swiftly and properly, which boosts sales and improves the credibility of a company.

C. Risk Reduction:

Natural disasters, geopolitical unrest, and economic changes are just a few of the many potential causes of supply chain interruptions. Businesses may detect and evaluate potential risks with the help of good supply chain management, put emergency plans into place, and increase resilience to lessen the effects of such interruptions.

D. Versatility & Adaptability:

Businesses can react swiftly to shifting market conditions, client preferences, and new trends with effective supply chains. In dynamic markets, adaptation is essential for maintaining competitiveness and capturing emerging possibilities.

E. Inventory management:

Good supply chain management assists in preventing stockouts and surplus inventory. Keeping the proper amount of inventory on hand helps to improve cash flow by ensuring that the right products are available when they are needed.

F. Collaboration:

Supply chain management encourages collaboration across a range of participants, particularly suppliers, retailers, distributors, and producers. Effective connections based on transparency and trust result in better collaboration, more efficient operations, and outcomes that are win-win for all parties.

Supply chain management is beneficial to the sector since it helps firms to increase productivity, save costs, boost client satisfaction, decrease risks, adjust to changing conditions, and conduct themselves responsibly in the age of globalization. The aforementioned benefits add up to a company’s long-term viability and profitability.

Now, Discuss the 5 essential steps to mitigate supply chain management. So, let’s begin.

2. 5 Steps to Manage Supply Chain Management

Assuring the effective flow of goods and services from the supplier to the consumer, in the end, requires a number of strategic activities. The following are five stages for managing supply chains successfully:

A. Identify and Assess Risks:

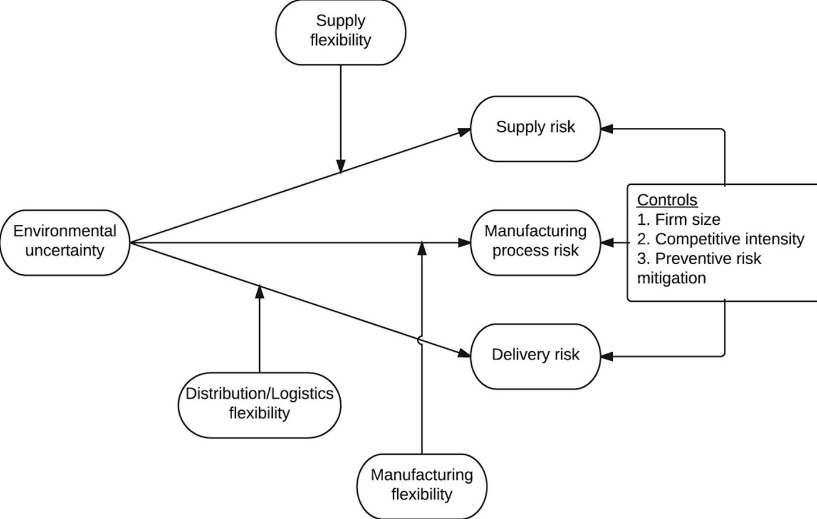

Although the primary goal of supply chain risk management is clearly stated as safeguarding the supply chain from any hazards that could negatively impact its capacity and consistency, the issue frequently arises from the challenge of initially identifying the risks. Supply chain professionals then have to evaluate the risks in order to come up with the best risk management plan after they have been discovered. The following are some typical risks and variables to take into account while performing a risk assessment:

a. Supplier Risks

Examine your suppliers’ dependability and stability. Take into account elements like capacity, financial stability, ability to produce, and location. Supply shortages may result from the operational or financial problems of a crucial supplier.

b. Supply Anticipation Risks

Stockouts or excess inventory can stem from inaccurate demand projections. Forecasting accuracy may be affected by shifts in consumer preferences, market demand, or unanticipated events.

c. Logistics and Transportation hazards:

Accidents, delays, or disruptions in the transportation system can have a big impact on the supply chain. Consider potential problems with shipping lanes, customs, taxes, and the accessibility of methods of transportation.

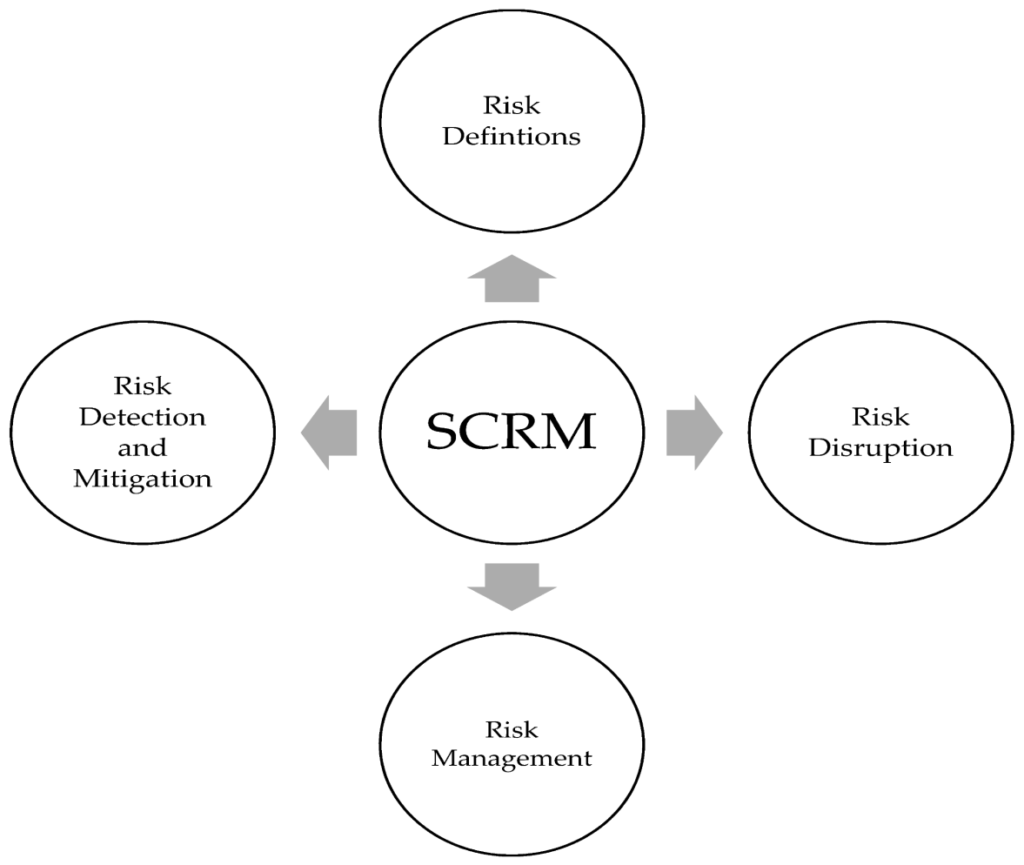

B. Develop a Risk Management Plan (SCRM):

To reduce supply chain risk and ensure a seamless and effective flow of goods and services, a thorough risk management plan must be developed. The essential steps in creating a supply chain risk management plan are listed below:

a. Determine Any Potential Risks:

To find any possible hazards in the supply chain, accomplish a complete risk assessment. Risks associated with suppliers, transportation, inventories, demand, geopolitical concerns, natural disasters, economic swings, etc. may fall under this category. Participate in this procedure with the necessary parties.

b. Risk Disruption:

Risk disruption is the idea that a system, process, or sector could be disrupted or interfered with by an event, condition, or innovation, potentially having unanticipated and unfavorable effects. Technology advances, market shifts, natural disasters, legislative changes, or unforeseen events like pandemics are just a few examples of the many factors that might cause this disruption.

c. Prioritizing risks:

Sort and rank the detected hazards according to how they might affect the supply chain. Concentrate on the risks that pose the greatest danger to the operations.

d. Develop a Risk Management Team

Create a specialized staff that will be in charge of managing the risk. Incorporate experts from several areas, such as senior management, operations, finance, and logistics.

C. Diversify Suppliers and Partners:

To reduce supply chain risk, it is important to diversify your partners and suppliers. Natural disasters, geopolitical events, economic changes, and even unforeseeable events like the COVID-19 pandemic can all cause supply chain interruptions. You may lessen the effects of future interruptions and create a more resilient supply chain by diversifying your sources of supply and working with numerous partners. The following are some major advantages and techniques for diversifying partners and suppliers:

a. Decreased Dependency:

If a single partner or supplier has problems, relying on them at all costs can be disastrous. By reducing dependence, diversification keeps your activities from coming to a total stop if one of your suppliers has issues.

b. Supply Continuity:

Having several suppliers or partners guarantees a constant supply of products and services, regardless of whether some sources are temporarily unavailable.

c. Increased Negotiation Authority:

By diversifying your business, you can take advantage of the increased competition among your suppliers and business partners to get better terms and prices.

d. Exposure to New Markets:

Forming alliances with other providers can give companies access to new clientele and potential markets.

D. Insurance Cooperative Partner:

Partnering with an insurance cooperative can be a smart move to reduce supply chain risk. Members of insurance cooperatives, who are often policyholders or parties who are insured, own and run these organizations. These cooperatives work for the interests of their members and seek to give members affordable access to risk management and insurance services.

Following are some methods for reducing supply chain risks by cooperation with an insurance cooperative:

a. Customize Insurance coverage:

Insurance coverage that is specifically customized to particular industries or sectors is a common area of expertise for insurance cooperatives. You can get insurance policies made to properly manage potential supply chain interruptions by working with a cooperative that is aware of the specific risks associated with your industry.

b. Common Risk Pooling:

When joining an insurance cooperative, you and the other member organizations make contributions to a collective risk pool. With the use of this pool, the cooperative is able to distribute the risk among its participants, making sure no one party suffers the whole weight of a significant supply chain interruption.

c. Risk Evaluation and Management:

Services for risk assessment and management are frequently provided by insurance cooperatives. Your supply chain’s weaknesses can be found, and you can put plans in place to reduce any possible risks.

d. Collaborative Network:

Network of Like-Minded Businesses Facing Comparable Hazards: As a member of an insurance cooperative, you are a part of this network. As a result, there are chances for collaboration, best practice exchange, and mutual learning.

E. Establish Contingency Plans:

A key component of effective risk management and preparation for any organization or person is the creation of contingency plans. Plans for contingencies assist in identifying potential hazards and providing solutions to reduce or address issues. A comprehensive guide for making backup plans is provided below:

Photo by Scott Graham on Unsplash

a. Establish aims:

Thoroughly state the goals of the backup strategy. What exactly do you intend to accomplish with the plan of action? This could entail protecting data and assets, guaranteeing business continuity, or reducing financial losses.

b. Create Strategies:

Create targeted strategies to address and mitigate each risk that has been identified. Your solutions can involve risk transfer, avoidance, reduction, or prevention, depending on the type of risk.

c. Resource Allocation:

Determine the resources (financial, personnel, and equipment) required to successfully implement the contingency plan.

Keep in mind that every business is different, so customize your backup plans to match the particular supply chain risks that your company is exposed to. To make sure that these strategies are effective, evaluate and test them frequently.

Conclusion

Supply chain risk reduction is no longer a choice but rather a requirement for companies seeking long-term success and sustainability in today’s volatile business environment. Organizations may create a solid and resilient supply chain that can survive a variety of difficulties by completing extensive risk assessments, diversifying suppliers, adopting technology, increasing redundancy, and keeping constant monitoring and review.

Businesses that take a proactive stance towards supply chain risk management will not only be shielded from potential setbacks but will also be better positioned for expansion and competitive advantage on a global scale. This blog was helpful for you? Do you have any queries about this blog? Let us know by commenting below.