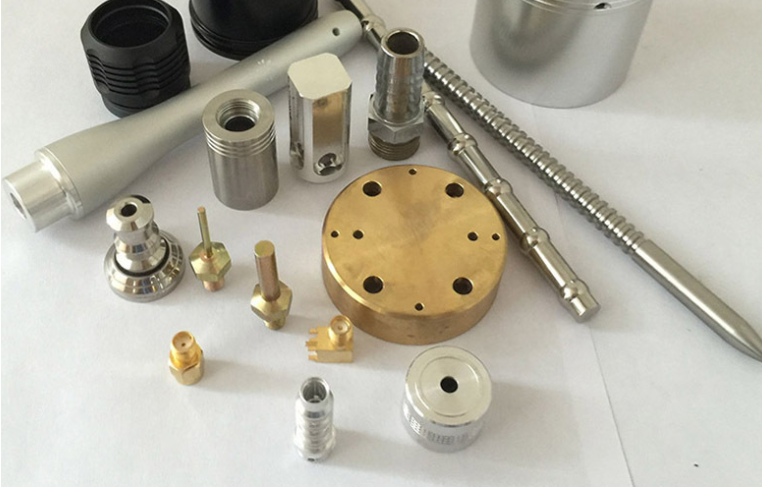

Metal processing

Hardware processing is raw materials (stainless steel, copper, aluminum, iron). ...) Use lathes, milling machines, drilling machines, polishing machines and other machinery to process various parts according to customer drawings or samples, such as screws, single-spin shaft products, automobile inspection profile accessories, CNC core machine 5G product series, automatic lathe aluminum profile stamping, etc. .

Process

The processing flow of hardware parts is to open materials according to the production needs. When you open some small parts and other small parts, you can go to the punching machine and then perform punching or CNC processing. This is a lot in the production of glasses parts and auto parts. And make the container: that is, after the material is opened and punched, it is burned, then sand and oil are sprayed, and then the accessories can be assembled before shipment. And for small hardware accessories, a lot of surface polishing, electroplating, or oil spraying are required. Then perform welding or screw assembly and shipment.

Classification

The subdivision of metal surface processing can be divided into: metal painting processing, electroplating, surface polishing processing, metal corrosion processing and so on.

Surface processing of hardware parts

- Paint processing: The hardware factory uses spray paint when producing large hardware products, and avoids rusting of the hardware through paint processing, such as daily necessities, electrical appliance casings, handicrafts, etc.

- Electroplating: Electroplating is also the most common processing technology in metal processing. The metal workpieces are electroplated through modern technology to ensure that the workpieces will not rust and mold for a long time. Common electroplating processing includes screws, stamping parts, and battery sheets. , Trinkets, etc.,

For mass production, use multi-tool semi-automatic lathe or automatic lathe. Machining large plate parts on vertical lathes. Machining large-scale long shaft parts on heavy-duty horizontal lathes.

For mass production, use multi-tool semi-automatic lathe or automatic lathe. Machining large plate parts on vertical lathes. Machining large-scale long shaft parts on heavy-duty horizontal lathes.

The characteristics of turning the outer surface are

- The tool is simple, easy to manufacture, easy to sharpen and install; 2. Stable cutting process, small cutting force fluctuations, high cutting speed, improved productivity;

3.Good machine tool versatility, outer circle, end face, inner hole, thread, chamfer Can be processed in one fixture. The accuracy of the mutual position of each side is easy to guarantee;

4. It is suitable for finishing of non-ferrous metal parts.