Dimensional Analysis to Production-Ready Models

●High-precision 3D scanning (accuracy up to 0.003mm)

●Structured light and laser metrology systems

●CMM verification with certified measurement reports

●Full material composition analysis

●Complete dimensional documentation

●Production-ready engineering drawings

Reverse engineering is the general process of analyzing a technology specifically to ascertain how it was designed or how it operates. This kind of inquiry engages individuals in a constructive learning process about the operation of systems and products. Reverse engineering as a method is not confined to any particular purpose, but is often an important part of the scientific method and technological development. The process of taking something apart and revealing the way in which it works is often an effective way to learn how to build a technology or make improvements to it.

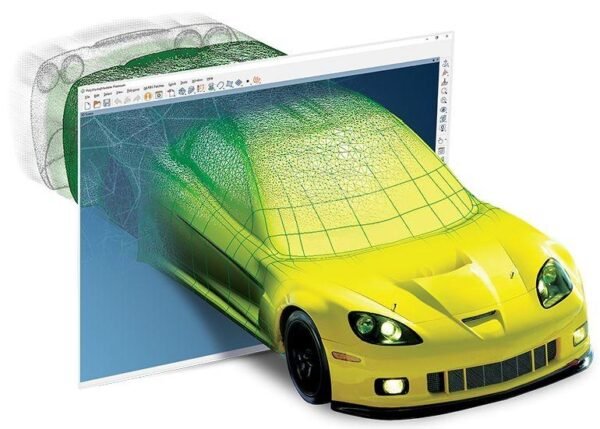

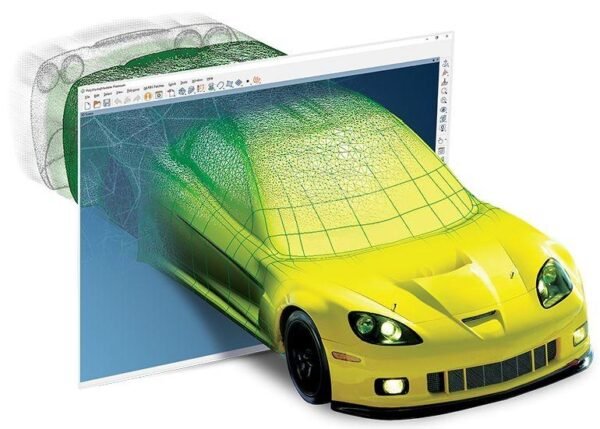

Reverse engineering in manufacturing refers to the generation of 3D images of manufactured parts when blueprints are not available to remanufacture parts. To reverse engineer a part, the part is measured by a coordinate measuring machine (CMM). As it is measured, a 3-D wire frame image is generated and displayed on a monitor. After the measuring is complete, the wire frame image is dimensioned. Any part can be reverse engineered using these methods

Under normal circumstances, we produce according to customers’ drawings. A set of rigorous 2D drawings and 3D drawings can ensure that the finished product achieves the design purpose. If you only have one sketch, then our experienced engineers can help you complete the drawing together. As long as you can provide complete data, it can be achieved.

But there is a situation, if you only have a physical product, how can you make the same product based on it? If the actual product is worn out, can you still make the same product as before it was worn out? Reverse engineering can solve these problems perfectly.

The role of reverse engineering:

Many customers’ designs are unique, so we attach great importance to confidentiality. Any of your designs and ideas will not be disclosed to third parties. We are also willing to sign a confidentiality agreement. We respect everyone’s intellectual property rights.

Under normal circumstances, we produce according to customers’ drawings. A set of rigorous 2D drawings and 3D drawings can ensure that the finished product achieves the design purpose. If you only have one sketch, then our experienced engineers can help you complete the drawing together. As long as you can provide complete data, it can be achieved.

But there is a situation, if you only have a physical product, how can you make the same product based on it? If the actual product is worn out, can you still make the same product as before it was worn out? Reverse engineering can solve these problems perfectly.

Reverse engineering is the general process of analyzing a technology specifically to ascertain how it was designed or how it operates. This kind of inquiry engages individuals in a constructive learning process about the operation of systems and products. Reverse engineering as a method is not confined to any particular purpose, but is often an important part of the scientific method and technological development. The process of taking something apart and revealing the way in which it works is often an effective way to learn how to build a technology or make improvements to it.

Reverse engineering in manufacturing refers to the generation of 3D images of manufactured parts when blueprints are not available to remanufacture parts. To reverse engineer a part, the part is measured by a coordinate measuring machine (CMM). As it is measured, a 3-D wire frame image is generated and displayed on a monitor. After the measuring is complete, the wire frame image is dimensioned. Any part can be reverse engineered using these methods

The role of reverse engineering:

Many customers’ designs are unique, so we attach great importance to confidentiality. Any of your designs and ideas will not be disclosed to third parties. We are also willing to sign a confidentiality agreement. We respect everyone’s intellectual property rights.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.