Lead-Time Reduction Strategies in CNC-Machined Parts: From Quote to Shipment

Reducing lead time in CNC machining is not a single improvement but a coordinated effort across every stage of production.

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

Reducing lead time in CNC machining is not a single improvement but a coordinated effort across every stage of production.

CNC machining and die casting serve distinct purposes. Your choice should consider precision, volume, and material needs.

Design for Manufacturability in CNC machining is about shaping a part so it can be produced efficiently without compromising function. When a component is designed

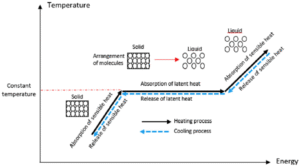

Material behavior influences every stage of CNC machining, from tool selection to inspection. Plastics, aluminum, steels, and superalloys each react differently to heat, pressure, and chip formation, which means a single approach can never deliver consistent results across all materials.

Understanding machining tolerance and allowance impacts manufacturing success, directly influencing cost, efficiency, and product quality. Accurate selection is paramount in meeting industrial demands.

Achieving consistent quality also relies on careful attention to toolpath strategies, chip evacuation, and process monitoring.

Automated quality inspection inside CNC machines has moved from being an optional upgrade to becoming a core part of modern machining. By measuring parts during production instead of waiting for offline checks, manufacturers gain faster feedback, better accuracy, and a more stable machining process overall.

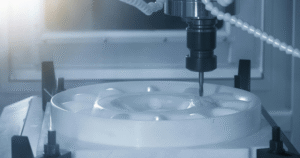

Profile milling’s precise, flexible approach suits high-tolerance industries by creating complex geometries, expanding its significance in various manufacturing sectors.

Solution treatment is essential in enhancing machined parts, offering improved strength and performance. By understanding its nuances, you can leverage it for high-quality, durable components.

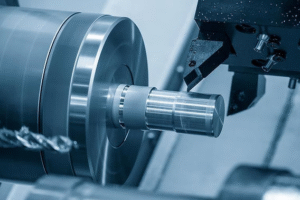

Effective chip control in CNC turning is essential for maintaining safety, surface integrity, and tool longevity, especially when working with difficult materials such as titanium, Inconel, and stainless steels. Achieving this requires a deep understanding of chip formation mechanics, tool geometry, and the influence of process parameters.

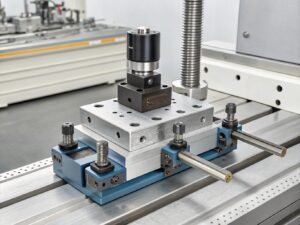

Properly securing a workpiece during CNC machining is vital. Any movement can lead to inaccuracies, affecting the final product’s quality. Workholding ensures parts remain stable,

Equally important is the maintenance and inspection of cutting fluids throughout their service life. Monitoring key parameters such as pH, concentration, and contamination ensures that the fluid continues to perform as intended.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.