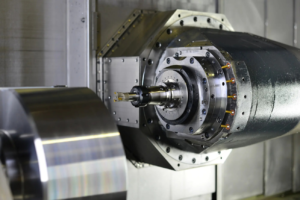

How Do CNC Machinists Select the Optimal Tool Steel for Custom Parts?

Selecting the optimal tool steel requires balancing material properties against application demands. By understanding classification systems, heat treatment effects, and property tradeoffs, we deliver superior custom machined parts that meet precise specifications while maximizing production efficiency.