1. Introduction

Although a maritime mast may appear simple in appearance, it is actually a product of careful engineering, particularly in its taper. Tapered masts are crucial to contemporary maritime architecture because they lower weight aloft, increase stability, and improve overall vessel performance. In the past, trial-and-error finishing, lengthy lead periods, and manual craftsmanship were crucial to the shape of these tapers.

The story has been altered by CNC (Computer Numerical Control) technology. Manufacturers may now produce precisely tapered marine masts with remarkable accuracy, smooth finishes, and reliable quality by fusing computerized design with high-precision machining. Tight tolerances, intricate geometries, and unique designs are now benefits rather than obstacles. In this blog, we discuss how CNC technology is revolutionizing the production of tapering maritime masts and why it is quickly becoming the norm in the marine sector.

2. Tapered Marine Mast Design Fundamentals

The goal of tapered maritime mast design is to strike the best possible equilibrium among aerodynamic performance, weight efficiency, and structural strength. In order to improve stability and handling, a mast must minimize mass aloft while withstanding complex loadings, such as bending from sail forces, compression from rigging, and dynamic loads from vessel motion. In order to select taper profiles that align strength where it is most needed and minimize weight where loads are lower, designers employ digital techniques to assess stress distribution and mast behavior under operating conditions. Before manufacture, advanced modeling techniques like finite element analysis (FEA) are frequently employed to optimize geometry and predict mast behavior.

Essential Ideas for Designing Tapered Masts

- Load Distribution & Structural Behavior: Determining taper designs that promote both safety and performance requires an understanding of how bending moments, axial compression, and dynamic loads impact mast stability.

- Aerodynamics: By improving airflow around sails and lowering aerodynamic drag, tapered profiles can increase responsiveness and speed.

- Material Influence: Taper choices and performance objectives are influenced by the stiffness, weight, and fatigue resistance of a material, such as carbon fiber composites or aluminum.

- Structural Analysis Tools: Engineers may assess stress concentration and deformation across tapered sections and refine design options with the aid of simulation tools like FEA.

3. Materials for Marine Mast Manufacturing

Strength, weight, durability, fatigue life, and corrosion resistance are all strongly impacted by the choice of material used in the production of naval masts. A marine mast must withstand cyclic loads from wind, rigging tension, and vessel motion while operating in challenging saltwater conditions. Materials with predictable structural behavior and good strength-to-weight ratios are given priority in modern mast designs.

1. Aluminum Alloys:

Aluminum alloys, due to their superior corrosion resistance, ease of machining, and affordability, especially marine-grade series like 6061 and 6082, are commonly employed. Aluminum masts are appropriate for cruising and commercial vessels because they provide a harmonious blend of rigidity and durability.

2. Composite Materials

High-performance and racing applications are increasingly utilizing composite materials, particularly carbon fiber-reinforced polymers (CFRP). Carbon fiber masts offer increased fatigue resistance, lower mass aloft, and better stiffness-to-weight ratios. Because of its anisotropic nature, designers can adjust strength and stiffness over the length of the mast, which works well with tapered designs.

3. Stainless Steel

Due to its weight, steel is rarely utilized for contemporary sailing masts, but it can still be used in certain military or utility applications where exceptional strength and durability are needed.

Material selection is a fundamental choice in mast design and manufacture since it has a direct impact on taper geometry, wall thickness, vibration behavior, and CNC machining approach.

4. Role of CNC Technology in Mast Production

Modern maritime mast manufacturing relies heavily on CNC (Computer Numerical Control) technology since it allows for great precision, repeatability, and design flexibility. Tight dimensional tolerances, consistent wall thickness, and smooth surface finishes are necessary for marine masts, particularly those with tapered designs, to guarantee consistent structural and aerodynamic performance. These specifications can be reliably fulfilled for both single prototypes and entire production runs due to CNC machining.

Complex mast shapes can be digitally modeled and instantly translated into machine instructions with CAD/CAM integration, which lowers manual variability and human error. Long, tapered profiles, accurate drilling for rigging attachments, and precision slotting for fittings can all be machined by multi-axis CNC machines while retaining alignment along the mast length.

Additionally, CNC technology allows manufacturers to modify mounting features, taper ratios, and mast diameters to suit various vessel types without the need for retooling. Furthermore, CNC machining shortens production cycles, minimizes waste, and enhances material use, making it a crucial facilitator of effective, superior maritime mast manufacturing.

5. CNC Machining Process for Tapered Masts

A precise digital model that specifies the taper profile, wall thickness, and mounting characteristics of the mast is the first step in the CNC manufacturing process for tapered marine masts. This model is transformed into exact toolpaths that direct machining operations along the length of the mast using CAD/CAM software. Maintaining alignment and dimensional accuracy during machining is crucial since masts are long, thin components.

Process Overview

- Design

- CAM toolpath Generation

- Multi-axis CNC machining

- Slotting/drilling for fittings

- Surface finishing

- Quality inspection.

Tapered profiles are frequently machined using multi-axis CNC machines, which enable controlled material removal while preserving uniform geometry. External taper machining, internal boring for consistent wall thickness, fitting slotting, and precision drilling for rigging attachments are some examples of operations. To avoid vibration, tool deflection, or surface flaws, especially in aluminum and composite materials, controlled feed rates and cutting settings are crucial.

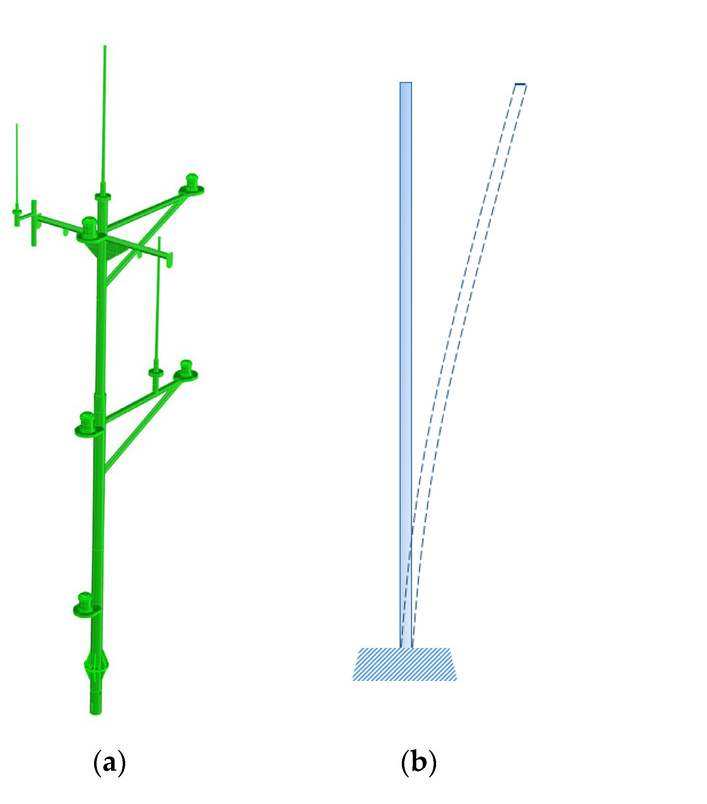

Mast on bridge top structural drawing.

Aerodynamic efficiency and structural performance are strongly impacted by the clean surface finishes and consistent taper precision that CNC machining guarantees. CNC machining is a dependable and scalable alternative for contemporary tapered mast manufacture because of the digital workflow's ease of design alterations and quick iteration.

6. Precision, Tolerances, and Dimensional Control

In order to guarantee structural integrity, aerodynamic performance, and safe operation, tapered maritime mast manufacture requires precision and stringent dimensional control. Stress concentrations, mast vibration, or rigging misalignment can result from even little variations in taper profile, wall thickness, or fitting locations. These tolerances are maintained in large part by CNC technology, which allows for consistent accuracy throughout several production runs.

Process Overview:

- CAD modeling,

- Tolerance specification,

- CNC machining with in-process measurement,

- Post-machining inspection, and

- Adjustment or finishing.

Tight tolerances are frequently needed for tapered masts, usually between ±0.1 and 0.3 mm, depending on the size and material of the mast. These tolerances are made possible by the use of multi-axis CNC machines in conjunction with real-time measurement tools like laser scanners or probe sensors.

Verifying wall thickness consistency, alignment along the mast length, and precise placement of drilled holes or fittings are further aspects of dimensional control. To ensure safety and performance in challenging marine settings, this degree of precision is crucial for both commercial vessels and high-performance racing yachts.

7. Surface Finishing and Post-Processing

In order to improve durability, corrosion resistance, and aerodynamic performance, surface finishing and post-processing are essential stages in the production of marine masts. Airflow, structural integrity, and coating adherence may be impacted by tool marks, micro-burrs, or uneven texturing on raw mast surfaces, even with exact CNC machining. In addition to ensuring a smooth surface and preventing environmental deterioration, post-processing gets the mast ready for final assembly.

Overview of the Process: CNC machining → deburring → sanding/polishing → surface treatment (coating or anodizing) → quality inspection.

Sanding, polishing, and anodizing are common finishing techniques for aluminum masts that increase corrosion resistance and create a smooth aerodynamic surface. Sanding and gel coat coating aid in achieving the appropriate stiffness, uniformity, and surface quality for composite masts. To increase their lifespan in challenging sea conditions, certain high-performance masts additionally go through electroplating, powder coating, or UV-resistant finishes.

In addition to improving appearance, post-processing eliminates drag, lowers stress risers, and increases longevity under cyclic loading and environmental exposure.

8. Quality Inspection and Testing Methods

In order to guarantee structural integrity, dimensional accuracy, and compliance with performance standards, quality inspection and testing are crucial in the construction of marine masts. Tapered masts must be able to sustain environmental stressors, torsional loads, and high bending moments without failing. Strict testing and inspection confirm that CNC-machined parts adhere to operating safety regulations and design parameters.

Important techniques for quality inspection consist of:

- Dimensional Inspection: Verifying taper profiles, wall thickness, hole location, and overall alignment using laser scanners, micrometers, or coordinate measuring machines (CMM).

- Non-Destructive Testing (NDT): Methods such as dye penetrant examination, X-ray, and ultrasonic testing are used to find internal flaws, cracks, or delamination in aluminum or composite masts.

- Load and Structural Testing: The mast's ability to safely support operational loads is confirmed by simulated bending, torsion, and fatigue tests.

- Surface and Coating Verification: Verifies that anodizing, powder coating, or gel coat finishes adhere to corrosion resistance, thickness, and adhesion requirements.

9. Benefits of CNC-Manufactured Tapered Masts

The construction of tapering marine masts has been transformed by CNC manufacturing, which offers unparalleled accuracy, efficiency, and repeatability. These advantages directly result in increased vessel safety, aerodynamic performance, and structural integrity.

Benefits:

- Accuracy and Precision: CNC machines create intricate tapered profiles with tight tolerances, guaranteeing accurate fitting locations, consistent wall thickness, and correct alignment.

- Repeatability and Consistency: All masts are made using the same digital design, which reduces variation and flaws between production runs.

- Material Efficiency: CNC machining maximizes the use of materials, cutting waste and allowing for lightweight masts without sacrificing strength.

- Customizability: CAD software makes it simple for designers to change taper ratios, lengths, and fitting positions, enabling quick prototyping and adaption for various vessels.

- Better Surface Finish: Smooth aerodynamic surfaces are ensured by CNC machining and post-processing, which lowers drag and increases sail efficiency.

- Improved Structural Function: Accurate machining guarantees the best possible load distribution, increasing the fatigue life, vibration resistance, and stiffness of the mast.

- Shorter Production Times: Manufacturers can scale effectively thanks to automation's reduction of manual labor and acceleration of production.

10. Manufacturing Challenges and Solutions

Tapered marine mast production presents a number of manufacturing issues, particularly for high-performance or custom vessels. Long, thin components require the maintenance of precision, structural integrity, material management, and surface quality. To guarantee durability, safety, and aerodynamic efficiency, these issues must be resolved.

Common Problems and Fixes:

- Keeping Dimensional Accuracy Over Extended Lengths:

Problem: During machining, long masts may vibrate or deflect, resulting in errors.

The solution is to use multi-axis CNC machines with real-time monitoring systems, support jigs, and sturdy fixturing.

- Material Stress and Deformation:

Problem: When machining forces are applied, thin walls or tapered portions may distort.

Optimize toolpaths and cutting speeds, and employ stress-reduction strategies either during or after machining.

- Surface Finish Quality:

Problem: Aerodynamics and coating adherence are impacted by tool marks, burrs, or uneven finishes.

Solution: Use post-processing methods like gel coating, polishing, sanding, and anodizing.

- Custom Designs with Complicated Taper Profiles:

Challenge: High-performance masts frequently feature integrated fittings or distinctive tapers.

Solution: Use CAD/CAM software to create accurate toolpaths and create digital simulations prior to manufacturing.

11. Future Trends in CNC Marine Mast Manufacturing

Automation technologies, sophisticated materials, and digital innovation are shaping the future of CNC maritime mast manufacturing. CNC technology keeps developing to suit the demands of the marine industry, which calls for masts that are stronger, lighter, and more aerodynamically efficient.

New Developments:

- Advanced Composite Materials: To reduce weight while improving stiffness and fatigue resistance, carbon fiber, graphene-reinforced polymers, and hybrid composites will gradually take the place of conventional aluminum.

- Multi-Material and Functionally Graded Masts: Additive manufacturing in conjunction with CNC machining may enable masts with integrated conduits, embedded sensors for real-time performance monitoring, and variable stiffness.

- Automation and Robotics Integration: Automated finishing and robotic handling will lower human error, increase reproducibility, and allow for more intricate taper geometries.

- Digital twins and simulation: Engineers will be able to reduce trial-and-error and material waste by simulating load situations, vibration, and aerodynamic performance prior to machining using virtual mast duplicates.

- Smart Quality Control: AI-driven flaw identification, laser scanning, and real-time in-process monitoring will improve accuracy, cut down on rework, and guarantee that safety regulations are constantly fulfilled.

- Sustainability: Mast production will become more ecologically friendly through waste reduction, material optimization, and energy-efficient CNC operations.

12. Conclusion

The manufacturing of tapering marine masts has been transformed by CNC technology, which offers accuracy, reliability, and efficiency. CNC procedures provide lightweight, robust, and aerodynamically optimized masts from design and material selection to machining, finishing, and quality inspection. The future of contemporary marine engineering will be shaped by CNC-manufactured masts, which are expected to become even more dependable, high-performing, and inventive due to new trends like improved composites, automation, and smart inspection.