Lead time in CNC manufacturing refers to the full duration from the moment a customer requests a quote to the moment finished parts arrive at their facility. This timeline covers quoting, programming, scheduling, machining, inspection, and shipping. In today’s competitive market, long lead times can slow growth, increase costs, and push customers toward faster suppliers. Shortening this cycle is therefore a direct advantage for both operational efficiency and client satisfaction.

This article explores practical strategies that help manufacturers reduce delays throughout the entire workflow. The focus is on digital quoting tools, optimized CAM methods, coordinated scheduling, integrated quality processes, and streamlined logistics. Each section highlights how small improvements at every stage create a faster, smoother path from inquiry to shipment.

Streamlining the Quoting and Order-Entry Stage

Speed at the quoting stage sets the tone for the entire manufacturing workflow. Many CNC projects lose days before a single toolpath is created because quoting relies on manual data entry, scattered communication, or unclear customer inputs. When the front end is slow or inconsistent, every downstream process must adjust. A faster and more structured quoting system reduces uncertainty and helps jobs reach programming and production without delays.

A strong quoting process focuses on three areas: digital tools that automate repetitive work, standardized information that eliminates confusion, and communication channels that keep both sides aligned. When these areas are optimized, lead times begin to shrink at the very first touchpoint.

Digital Quoting Platforms

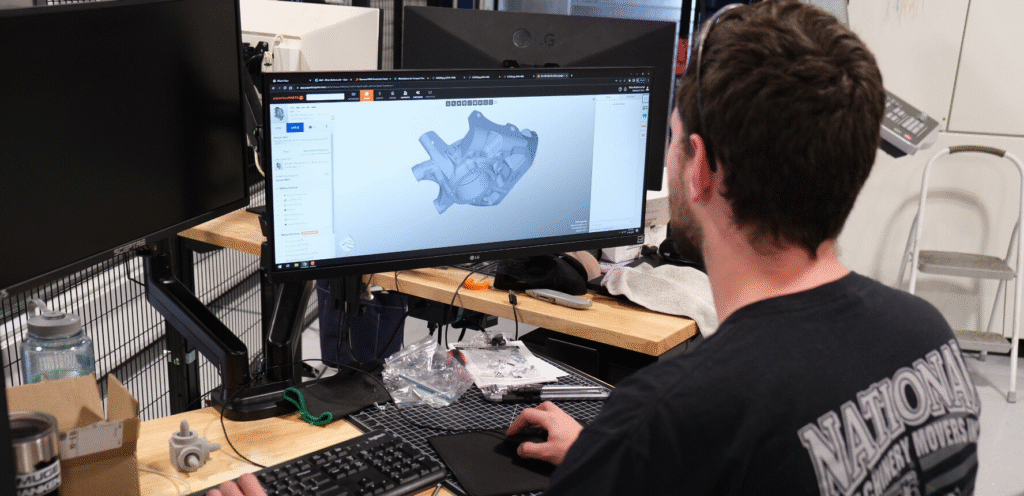

Modern quoting software can dramatically shorten the review and calculation stage. These systems analyze CAD files, extract features, and estimate time and cost far more quickly than a manual approach. Automated quoting also ensures that different engineers do not produce different pricing structures for similar parts.

Quoting Software for CNC Machining

Key advantages include:

- Faster response times

- Reduced risk of manual calculation errors

- Consistent pricing logic across materials and geometries

Using these platforms also helps sales teams give realistic delivery timelines because the software can connect with scheduling data or previous job records.

Standardized Data Inputs

Even the most advanced quoting system slows down when the incoming files are incomplete or inconsistent. Establishing clear requirements for CAD formats, material specifications, and tolerances prevents unnecessary back-and-forth and reduces the chances of quoting the wrong revision. Clear inputs also help engineering teams validate manufacturability without waiting for clarifications.

Practical steps include:

- Requesting uniform CAD formats for all quotes

- Asking customers to specify surface finishes, tolerances, and threads in one structured form

- Providing a checklist that customers must complete before submission

When customers follow a consistent format, the quoting team works faster and avoids revisions.

Real-Time Communication

Communication gaps can increase lead times more than the machining process itself. Integrating quoting tools with a CRM or messaging platform creates a single place to track updates, approvals, and questions. Instead of waiting for long email chains, both sides can finalize requirements quickly.

Useful practices include:

- Automated notifications for quote status and approval

- A centralized chat thread for technical clarifications

- Quick response policies for both internal teams and customers

A fast and predictable communication loop helps confirm details early, which prevents delays when the job moves into CAM programming and production.

Workflow Optimization and Data Integration

Once a job enters the production system, the next source of delays often comes from disconnected workflows. When departments use separate software, manual updates, or paper-based communication, it becomes difficult to maintain real-time visibility. Small uncertainties, such as unclear machine availability or missing tooling, can quickly add hours or days to a project. Integrating data and aligning digital workflows allows teams to see issues earlier and coordinate decisions with fewer interruptions.

CNC machining: integrating Big Data and predictive analytics

A strong workflow depends on synchronized information between planning, programming, machining, quality, and shipping. Centralized data eliminates unnecessary handoffs and helps every team understand the status of each job without relying on constant check-ins.

Connected ERP–MES Systems

Linking ERP and MES platforms creates a continuous flow of information from scheduling to machine-level execution. With this connection, planners know which machines are free, which tools are available, and which orders are behind schedule. Operators can also see job priorities and required setups without searching for the latest update.

Key benefits include:

- Real-time visibility of machine status

- Automatic prevention of double-booked machines

- Early alerts for material shortages or missing tools

Integrated systems help management make faster decisions and reduce idle time across the shop floor.

Job Prioritization and Batch Management

Even with accurate data, production slows down when priorities are unclear. Visual scheduling tools such as digital dashboards or Kanban boards help teams track job movement from quoting through machining. When every operator can see the same information, there is less confusion about which parts should run first.

Batch management is another important element. Grouping similar materials or setups reduces the time spent changing fixtures, swapping tools, or adjusting machine parameters. For example, running all aluminum parts together or completing all operations that require the same cutter helps maintain momentum and improve predictability.

Effective practices include:

- Categorizing jobs by material or complexity

- Running families of parts together when possible

- Setting visual rules for urgent or high-value orders

Clear priorities keep machines engaged and reduce unnecessary downtime.

Eliminating Manual Handoffs

Paper travelers and handwritten notes slow down production and introduce room for errors. Digital job packets provide a more reliable way to transfer information between teams. These packets can include CAD files, setup sheets, tool lists, inspection plans, and shipment details in one structured location.

Barcode or QR code tracking adds another level of efficiency. Scanning updates the system instantly, which helps managers see where each job is at any moment. This reduces the need for phone calls or walkthroughs to locate parts.

Digital handoffs improve traceability and create a consistent workflow from station to station. As a result, fewer tasks wait in queues, and lead times naturally shrink.

Advanced CAM Programming Strategies

Once a job enters programming, the quality of the CAM process has a direct influence on machining time and overall lead time. Inefficient toolpaths, unclear setups, or outdated libraries can slow production before the part even reaches a machine. Strong CAM strategies shorten cycle time, reduce tool changes, and prevent rework. They also help programmers work faster because common decisions are already standardized. When CAM is optimized, machining becomes predictable, and parts move through the shop with fewer delays.

advanced CAM software capabilities for CNC programmers

A mature CAM workflow focuses on standardization, intelligent toolpaths, and thorough verification. These three elements work together to reduce programming time, cut machining hours, and minimize the risk of restarting a job after discovering an error.

Template-Based CAM and Feature Recognition

Creating a new program from scratch for every part leads to long lead times. CAM templates allow programmers to reuse proven setups, tools, and strategies. These templates can include material-specific cutting parameters, standard roughing operations, finishing strategies, and tool libraries. With this structure in place, a programmer only needs to adjust the details that are unique to the part.

Feature recognition tools take this one step further. They automatically identify holes, pockets, threads, and bosses, then apply the correct machining strategy. This reduces manual decisions and helps maintain consistency across jobs.

Practical advantages include:

- Faster programming for recurring geometries

- Reduced the chance of overlooking small features

- Consistent tool selection and feeds across materials

This approach creates predictable outputs that align well with scheduling.

Adaptive Toolpaths and High-Efficiency Milling

Modern toolpath strategies reduce cycle time by keeping the cutter engaged at a constant load. Traditional toolpaths often produce heavy engagement in corners and light engagement in straight sections. Adaptive strategies avoid these fluctuations by controlling step-over, tool engagement, and chip thickness. This results in smoother machining, higher removal rates, and longer tool life.

High-efficiency milling builds on this concept. It focuses on deeper axial cuts with small radial engagements, allowing the machine to remove material quickly with less heat buildup. This reduces air cutting and keeps the machine productive throughout the operation.

When used correctly, these strategies can:

- Cut cycle time across most materials

- Reduce tool wear and improve surface consistency

- Allow higher feed rates without compromising accuracy

These benefits directly shorten machining hours and free machines for additional work.

Simulation and Verification

Simulation is one of the most effective ways to prevent delays caused by programming errors. Digital twins and verification tools allow programmers to test toolpaths virtually. They can identify collisions, gouges, or unsafe moves before the part reaches the machine. This reduces the need for on-machine adjustments and saves operators from restarting jobs when issues appear mid-cycle.

Virtual CNC software for 3D CNC machine simulation

Simulation also helps optimize feeds and speeds based on real machine capability. By refining parameters before the first cut, programmers can shorten setup time and reduce the risk of scrap.

Strong verification practices provide:

- Early detection of programming issues

- Lower rework and scrap rates

- Smoother handoff to machine operators

This stage protects the schedule and keeps machines cutting instead of troubleshooting.

Maximizing Machine Utilization

Once programming is complete, the next major factor influencing lead time is how well the machines are used. Even the best toolpaths cannot compensate for avoidable idle hours, slow changeovers, or unplanned maintenance. Many shops lose more time through underutilization than through actual cutting processes. Improving utilization requires balanced scheduling, reliable machines, and efficient setups. When these elements work together, each machine contributes more productive hours, and jobs flow through the shop with fewer delays.

A strong utilization strategy aims to reduce every form of downtime, including waiting for materials, waiting for operators, and waiting for tools. By improving predictability and removing interruptions, a shop can increase throughput without adding new equipment.

Smart Scheduling and Predictive Maintenance

Scheduling affects utilization more than any single machining technique. When jobs are matched to the wrong machine or queued without clear planning, production slows. Smart scheduling systems analyze job complexity, required tolerances, and machine capability to assign work efficiently. They also help balance workloads so that no machine sits idle while others are overloaded.

Predictive maintenance supports this effort by preventing unexpected stoppages. Instead of waiting for breakdowns, sensors and software monitor spindle load, vibration, and tool wear. Early alerts help teams schedule maintenance during low-impact periods.

Core benefits include:

- More accurate job assignments

- Fewer interruptions from machine failures

- Improved reliability across the production line

Together, these practices create stable output and protect delivery timelines.

Multi-Axis and Lights-Out Machining

Increasing machine capability directly contributes to shorter lead times. Multi-axis machines can complete multiple operations in one setup, which reduces fixture changes, refixturing errors, and handling time. They also allow more complex geometries to be machined without multiple machines or additional setups.

Lights-out machining pushes utilization even further. With robotic loading, pallet changers, or automated workholding, machines can run unattended during nights or weekends. This extends production hours without increasing labor requirements. Even partial automation can significantly expand available spindle time.

Shops often gain:

- Reduced operator dependency

- Higher throughput during off-hours

- Fewer setup interruptions between cycles

This strategy is especially valuable when managing high-volume or repeat work.

Tool Management and Setup Reduction

Tooling delays are one of the most common causes of machine downtime. Standardized tool libraries, presetting systems, and quick-change fixtures help operators begin production faster. When tools are prepared in advance, machines spend more hours cutting and fewer hours waiting.

Setup reduction also depends on consistent fixturing and documentation. Clear setup sheets, accurate offsets, and repeatable workholding allow operators to replicate setups across shifts without trial and error. This improves accuracy and lowers the risk of mistakes that require rework.

Effective practices include:

- Using presetters for faster tool offsets

- Creating standard fixture plates for recurring jobs

- Maintaining organized tool carts with verified inventory

With fewer interruptions between tasks, machines stay productive and lead times naturally improve.

Inspection and Quality Planning

Quality control has a significant influence on lead time, often more than machining itself. Even when parts are produced quickly, delays occur if inspection creates a bottleneck or if quality issues force rework. A strong quality plan starts before the first setup and continues throughout production. Integrating inspection into the workflow allows teams to detect deviations early, prevent scrap, and keep parts moving without unnecessary pauses.

Quality Control in Manufacturing

A reliable quality strategy focuses on three areas: early detection, continuous monitoring, and data-driven improvements. When inspection is aligned with machining instead of operating as a separate stage, lead times shrink, and final approvals become much more predictable.

In-Process Inspection

In-process inspection allows manufacturers to measure features while the part is still on the machine. Probing systems, laser sensors, and touch probes can verify dimensions quickly without removing the part. This approach catches small deviations early, often before they affect downstream features.

In-process checks help operators adjust parameters such as tool offsets or wear compensation in real time. This reduces the likelihood of producing an entire batch of nonconforming parts and avoids the long delays that come from restarting a job.

Key advantages include:

- Immediate detection of machining errors

- Lower scrap rates

- Reduced time spent on post-machining corrections

By identifying issues during cutting, production remains steady and predictable.

Parallel Quality Workflows

Traditional inspection workflows often create a queue where parts wait for CMM availability or manual measurements. Running an inspection in parallel with machining prevents these delays. When parts are measured as they move through each stage, the final inspection becomes a confirmation rather than a full evaluation.

Optical scanners, portable CMMs, and shop-floor gauges support faster checks and allow multiple operators to inspect parts without interrupting the main quality room. This helps maintain momentum and reduces bottlenecks at the end of production.

Effective practices include:

- Scheduling inspections alongside machining

- Using fast measurement tools suitable for in-process checks

- Establishing clear acceptance criteria for each stage

Parallel workflows keep quality aligned with production rather than following behind it.

Data-Driven Quality Control

Inspection data gains value when it is recorded, organized, and analyzed. Tracking measurement trends across batches helps identify recurring problems such as tool wear patterns, unstable fixturing, or programming inconsistencies. This information supports long-term improvement and helps prevent repeated delays.

Data-driven quality also improves communication between programmers, machinists, and inspectors. When teams see where errors originate, they can adjust toolpaths, refine cutting parameters, or modify workholding.

Practical benefits include:

- Faster root-cause identification

- Improved process stability

- Reduced time lost to repeated quality issues

With structured data, shops move from reactive correction to proactive planning.

Coordinated Shipping and Logistics

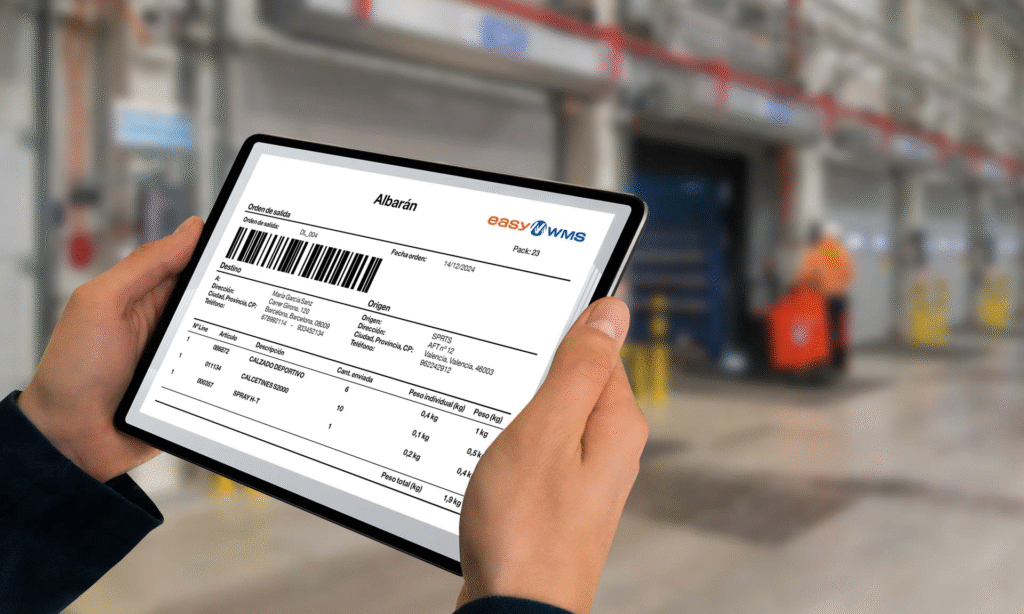

Even when machining and inspection run smoothly, delays at the shipping stage can undermine the entire lead-time improvement effort. Packaging, documentation, and courier coordination often remain manual and inconsistent, which leads to last-minute bottlenecks. A structured logistics plan ensures that finished parts leave the facility without unnecessary waiting periods. By preparing packaging, tracking, and communication earlier in the workflow, manufacturers avoid the final-day rush that frequently slows delivery.

A coordinated logistics process prioritizes early planning, digital integration, and clear communication. These elements work together to ensure that once a job is approved, it moves out of the facility quickly and reaches the customer on time.

Early Packaging Planning

Packaging should be prepared long before the machining stage ends. Many delays occur because teams only begin packing once parts are finished, which introduces additional handling and decision-making. Creating standardized packaging procedures helps eliminate this unpredictability.

Practical steps include:

- Preparing boxes, foam inserts, labels, and protective wraps during production

- Using predefined packaging rules based on part size and fragility

- Storing packaging materials near the shipping area to reduce walking time

Early planning ensures that parts are ready for dispatch as soon as they pass inspection.

Digital Shipment Tracking

Digital tools help reduce manual paperwork and speed up coordination with shipping partners. When ERP systems are integrated with courier APIs, labels, tracking numbers, and dispatch forms can be generated automatically. This reduces administrative time and lowers the chance of shipment errors.

Automation also helps teams provide more accurate delivery estimates. Customers can receive immediate tracking links once the shipment is created, which improves transparency and reduces follow-up requests.

Key advantages include:

- Faster creation of shipping documents

- Automatic tracking updates

- Fewer manual data entry steps

This creates a smoother transition from production to delivery.

Customer Communication

Clear communication at the shipping stage helps maintain customer confidence and minimizes support requests. Automated notifications can inform customers when the shipment is prepared, dispatched, and in transit. This removes uncertainty and provides a complete view of the order status.

Practical communication strategies include:

- Sending delivery estimates through email or a customer dashboard

- Providing tracking details immediately after label creation

- Updating customers proactively if courier delays occur

Strong communication ensures that the final stage of the job is as reliable and predictable as the machining process itself.

Conclusion

Reducing lead time in CNC machining is not a single improvement but a coordinated effort across every stage of production. When quoting is fast, workflows are synchronized, CAM strategies are optimized, machines run efficiently, and inspection is integrated into daily operations, the entire process becomes more predictable. Small efficiencies at each step compound into significant reductions in overall turnaround time, allowing manufacturers to deliver parts faster and with greater consistency.

Digital integration, standardized inputs, and proactive scheduling form the foundation of a reliable lead-time strategy. Shops that adopt these practices gain more than operational speed. They build customer confidence, strengthen long-term relationships, and create a competitive advantage in a market that values fast and dependable delivery.