Hybrid manufacturing brings additive manufacturing and CNC machining into a single, connected workflow. Instead of choosing one process over the other, engineers can print a near-net shape and finish it with precise machining. This approach removes many limitations found in using either method alone, which is why it continues to gain interest across advanced industries.

Hybrid Manufacturing Technology

Many companies are adopting hybrid methods because they offer higher precision, lower material waste, and the ability to produce geometries that traditional machining cannot reach. The combination also reduces the number of setups and shortens the path from concept to finished part. When used correctly, it delivers both flexibility and accuracy.

This article focuses on the practical side of hybrid manufacturing. You will see how to design parts for print-first and machine-later workflows, how to choose suitable materials, how to manage printed to machined interfaces, and how to apply the right inspection and quality control strategies.

Why CNC Machining and Additive Manufacturing Work Better Together

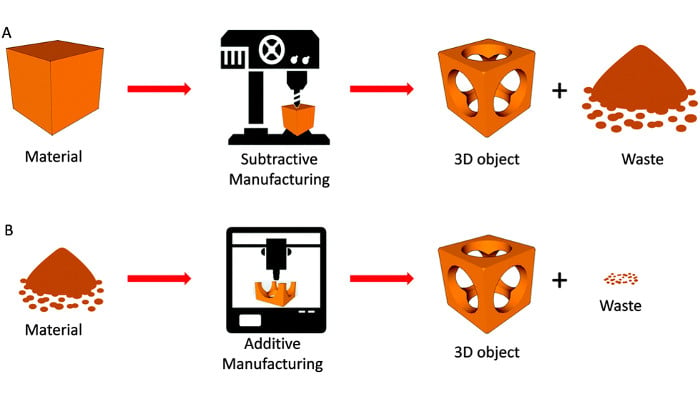

Combining CNC machining and additive manufacturing creates a workflow that uses the strengths of both methods. Additive manufacturing builds complex geometries with minimal material waste, while machining delivers the final accuracy, surface finish, and reliability required for production parts. When these capabilities are connected in a single workflow, manufacturers can create components that were previously difficult or too expensive to produce.

Hybrid manufacturing works well because each process covers what the other lacks. Additive methods create internal features and lightweight structures that would normally be impossible to reach with cutting tools. Machining then corrects tolerances, improves surface quality, and ensures consistent performance.

Benefits of the Hybrid Approach

Once both processes are used together, several advantages become clear. These benefits support everything from early prototypes to high-value production parts.

- Improved dimensional accuracy

Printing the near net shape and machining the final surfaces allows tighter tolerances and consistent part quality.

- Reduced material waste

Most of the geometry is printed close to its final form, so machining removes only minimal stock, which lowers material consumption.

- Ability to manufacture complex internal features

Internal channels, lattice structures, and organic forms can be printed with ease, then refined with machining only where accuracy is needed.

- Shorter prototyping and iteration cycles

Design changes can be reprinted quickly, while machining ensures that critical interfaces, fits, and surfaces still meet specifications.

These benefits create a workflow that is both flexible and precise, leading to more efficient development and stronger control over final performance.

Typical Applications

Hybrid manufacturing is most valuable in industries where complex geometry, reliable performance, and lightweight structures matter. The combination of printing and machining gives engineers the freedom to create advanced shapes without sacrificing accuracy.

- Aerospace and turbine components

Turbine blades, housings, and airflow components often require internal channels for cooling. These channels can be printed, while machining ensures precise aerodynamic surfaces and tight-fitting interfaces.

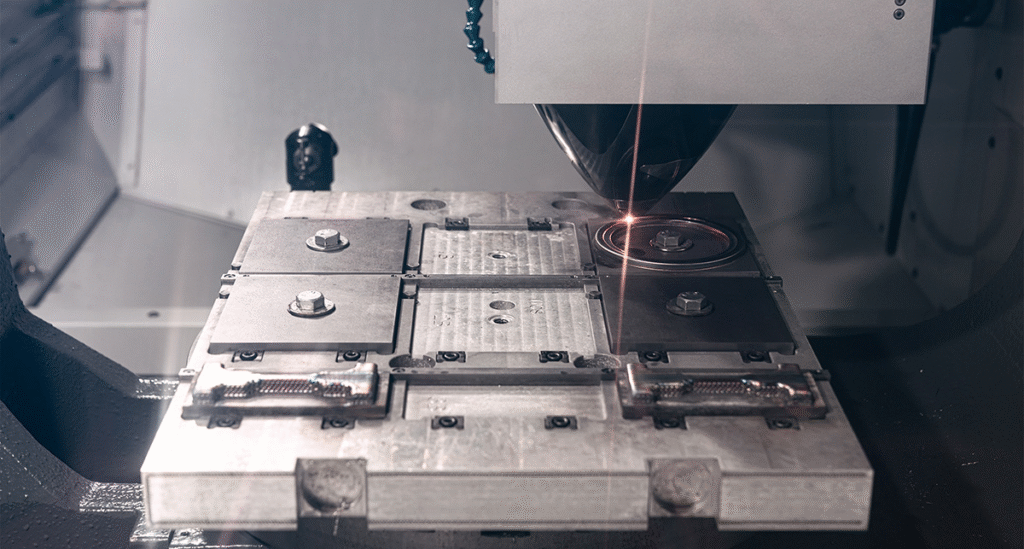

- Conformal cooling mold inserts

Additive manufacturing allows cooling lines to follow the exact shape of the mold cavity. Machining then finishes the key surfaces that contact the molded part. This combination improves cycle time and product quality.

- Titanium medical implants

Implants benefit from printed porous structures that support bone integration. Machining is used to finish the connection points, mounting features, and any surfaces that require high accuracy.

- High-performance prototype components

Racing, robotics, and aerospace teams often need lightweight prototypes that still meet exact functional requirements. Printing creates the optimized structure, while machining delivers the final precision.

These applications show how hybrid workflows solve real engineering challenges by combining geometric freedom with dependable finishing quality.

Designing Parts for Hybrid Manufacturing Workflows

Designing parts for hybrid manufacturing requires careful planning. Engineers must consider which features are best printed and which should be machined. Effective design ensures that the final part meets functional requirements while minimizing unnecessary machining and material waste. Proper planning also reduces production errors and simplifies post-processing.

The design phase focuses on three main aspects: creating near-net geometries, assigning features to the appropriate process, and planning machining allowances and fixturing. These considerations are critical to achieving a workflow that leverages the strengths of both additive and subtractive methods.

Design for Near-Net Geometry Printing

Printing a part close to its final shape reduces the amount of machining required. Near-net designs also help conserve material and shorten lead times.

Key considerations include:

- Minimize machining stock

Leave only the material necessary for final finishing. Avoid overbuilding unnecessary thickness that will later be removed.

- Plan internal features and channels

Design channels, cavities, or lattice structures during the printing stage. Ensure these features are accessible and maintain structural integrity.

- Consider print orientation and structural load paths

Orientation affects surface finish, strength, and support requirements. Align critical features to optimize load-bearing capacity and reduce post-processing.

Assigning Features to AM vs CNC

Identifying which features are printed and which are machined improves efficiency and accuracy.

- Printed features

- Internal channels

- Organic or lattice structures

- Lightweight components where geometry cannot be machined

- Machined features

- Surfaces requiring high-dimensional accuracy

- Sealing or mating interfaces

- Threaded holes and precise mounting points

Clear separation of printed and machined areas allows the workflow to take advantage of additive freedom without compromising precision.

Machining Allowances, Supports, and Fixturing

Careful planning of machining allowances and fixtures ensures smooth post-processing.

- Machining allowances

Leave adequate stock for finishing without overbuilding, which can increase machining time and cost.

- Access for toolpaths

Ensure all critical surfaces are reachable by milling or turning tools. Consider cutting angles and tool dimensions.

- Early fixture and datum design

Integrate fixturing points during design to secure the part during machining. Use stable reference datums to maintain alignment and tolerance throughout production.

By following these design principles, engineers can create parts that fully benefit from hybrid manufacturing while minimizing errors and maximizing efficiency.

Choosing the Right Materials and Managing Interfaces

Material selection is critical in hybrid manufacturing. The material must support both additive printing and subsequent machining. Each material behaves differently during printing, heat treatment, and machining. Understanding these behaviors ensures part stability, dimensional accuracy, and long-term performance.

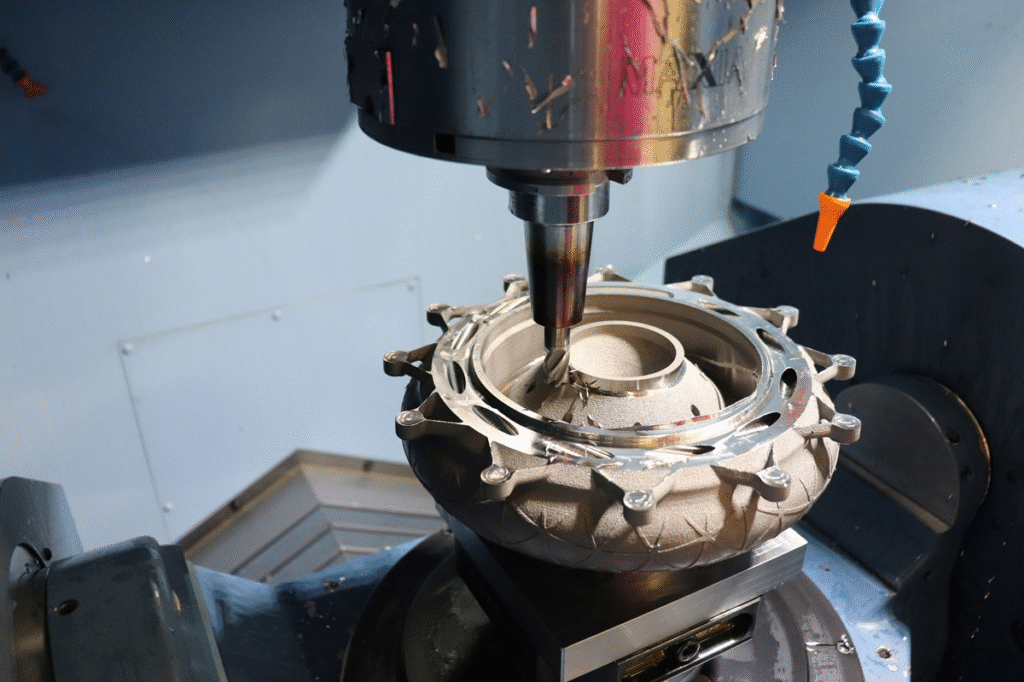

Hybrid Manufacturing Combines 3D Printing

Another important aspect is the interaction between printed and machined surfaces. Improper interface design can lead to stress concentration, poor surface quality, and difficulty in machining. Careful planning helps prevent defects and ensures the final part meets functional requirements.

Materials That Support the Hybrid Process

Some metals and alloys are better suited for hybrid workflows due to their mechanical properties and printability. Selecting the right material depends on strength requirements, thermal behavior, and machining characteristics. Common choices include:

- Titanium (Ti-6Al-4V)

High strength-to-weight ratio, corrosion resistant, suitable for aerospace and medical applications.

- Stainless steels

Good mechanical properties, widely used in tooling, mold inserts, and structural components.

- Nickel-based superalloys

Retain strength at high temperatures, ideal for turbine and high-performance components.

- Tool steels

Excellent wear resistance, suitable for molds, dies, and high-stress parts.

- Aluminum alloys

Lightweight, easy to machine, and widely used in automotive and aerospace applications.

Printed-to-Machined Interface Design

The interface between printed and machined areas must be carefully managed to avoid deformation and ensure proper machining.

- Overbuild areas for precision machining

Leave extra material where tolerances are tight or surface quality is critical.

- Avoid sudden thickness changes

Smooth transitions reduce stress concentrations and improve machinability.

- Use fillets or transitions where needed

Rounded edges at junctions prevent cracking and support stable tool engagement.

Heat Treatment and Stress Relief

Post-processing can stabilize the part and improve machinability. Heat treatment is often required to relieve residual stress from printing and optimize mechanical properties.

- Reduce residual stress

Annealing or stress-relief treatments prevent warping during machining.

- Improve surface finish

Certain treatments can enhance surface hardness and reduce roughness before final machining.

- Stabilize geometry before machining

Heat treatment ensures dimensions remain consistent, reducing rework and scrap.

Proper material selection and careful interface planning are essential for hybrid manufacturing. When combined with appropriate heat treatment, these steps improve part performance and manufacturing reliability.

Production Workflow, Tooling, and Quality Checks

Executing a hybrid manufacturing process requires a well-defined production workflow. Understanding the correct sequence of operations, planning toolpaths, and integrating quality checks ensures parts meet design specifications efficiently. Poor workflow planning can lead to excessive machining, material waste, or dimensional inaccuracies.

Hybrid Manufacturing | Hybrid CNC Parts

Hybrid manufacturing workflows vary depending on the equipment and material used, but all rely on careful coordination between additive and subtractive stages. Proper tooling, fixturing, and inspection are crucial for achieving consistent, high-quality results.

Production Sequences

Hybrid manufacturing can follow different sequences depending on part complexity and process type. The sequence impacts material behavior, machining access, and overall efficiency.

- Print first, then the machine

Common for most hybrid setups. The part is printed close to the final geometry and then machined to achieve precise tolerances.

- Machine first, then add material to the substrate

Used when a high-precision base is required. Additive processes are applied selectively to build additional features or repair worn surfaces.

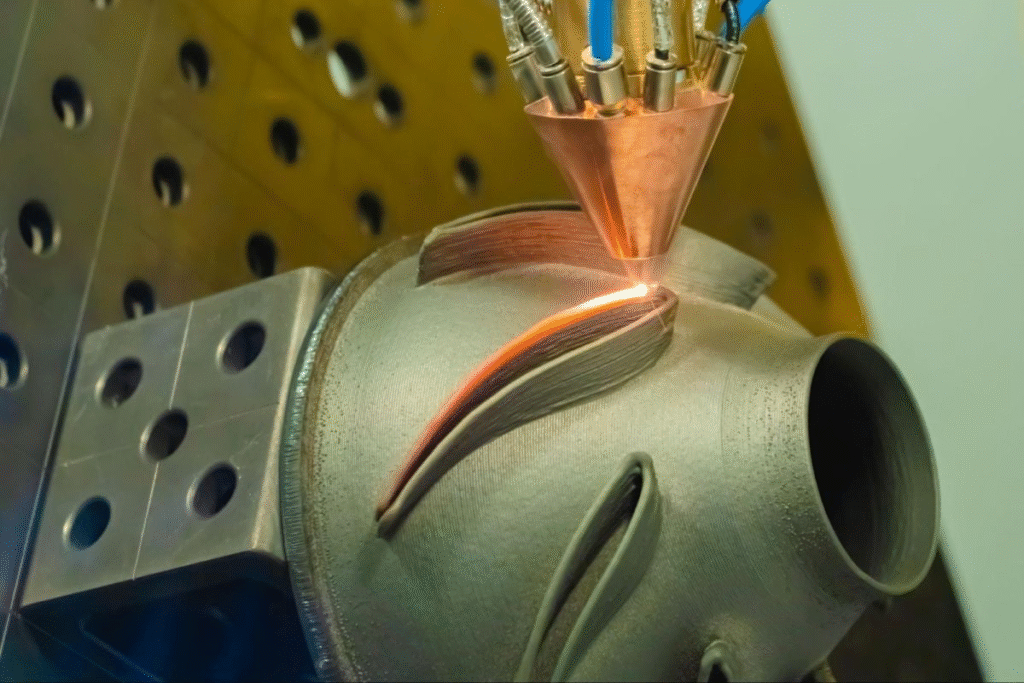

- Direct energy deposition (DED) hybrid machines

Some machines integrate additive deposition and CNC machining in one platform. These systems allow simultaneous build and finish operations, reducing setup time and improving alignment.

Toolpaths and Fixturing

Proper toolpath planning and fixture design are essential when machining printed surfaces. Irregular geometries require adaptive strategies.

- Managing irregular printed surfaces

Scanned or digital models of the printed part guide machining to ensure accurate material removal.

- Datum references and probing

Establish stable datums to maintain alignment during multiple setups. Probing can verify position and adjust toolpaths dynamically.

- Adaptive roughing and high-speed finishing

Roughing removes excess material efficiently while finishing ensures the required surface quality and dimensional accuracy.

Inspection and Quality Control

Quality control is critical to validate both printed and machined features. Hybrid parts often contain complex internal geometries that are difficult to inspect with traditional methods.

- CT or 3D scanning for internal features

Non-destructive scanning reveals hidden channels, lattice structures, and porosity.

- In-process metrology

Monitoring dimensions and surface conditions during machining helps catch deviations early.

- Checking for porosity and surface defects

Surface roughness, micro-cracks, and internal voids can impact performance. Early detection ensures parts meet functional requirements.

By integrating careful workflow planning, precise tooling, and thorough quality checks, hybrid manufacturing delivers parts that meet both design intent and functional requirements efficiently.

Cost, Efficiency, and Practical Limitations

Hybrid manufacturing offers significant advantages in cost and efficiency, but it is not without limitations. Understanding both the benefits and constraints helps companies determine where this approach is most effective. Decisions around equipment, materials, and process planning directly influence production costs, lead times, and part quality.

While hybrid workflows reduce waste and speed up development, high equipment investment and process complexity can be challenging. Careful evaluation ensures that hybrid methods are applied where they provide real value rather than adding unnecessary cost or complexity.

Cost and Lead-Time Advantages

Integrating additive and subtractive processes can provide measurable efficiency gains. These gains are realized through reduced material usage, faster production of complex components, and streamlined operations.

- Reduced material removal

Near-net printing reduces the amount of material that must be machined away, lowering both raw material costs and machining time.

- Faster manufacturing of complex parts

Complex geometries that would require multiple setups in traditional machining can be printed, then finished in a single machining step.

- Lower tooling and setup time

Additive printing can create features that eliminate the need for custom tooling or extensive fixture setups, saving time and cost.

Drawbacks and Constraints

Despite the advantages, hybrid manufacturing has practical limitations that must be considered before adoption.

- High equipment cost

Hybrid machines and integrated systems require significant upfront investment, which may not be justified for low-volume production.

- Process knowledge and setup complexity

Successful hybrid manufacturing requires expertise in both additive and subtractive processes. Improper planning can lead to errors, rework, or damaged parts.

- Not ideal for every part or production volume

Simple components with standard geometries or very high-volume production may be more efficiently produced using traditional methods alone.

Balancing these benefits and constraints ensures that hybrid manufacturing is applied where it provides the greatest return, maximizing both performance and cost efficiency.

Process Optimization and Best Practices for Hybrid Manufacturing

Achieving consistent quality in hybrid manufacturing requires more than simply combining printing and machining. Process optimization ensures that each step is efficient, repeatable, and aligned with the final part requirements. Effective hybrid workflows balance material behavior, tool selection, thermal effects, and scheduling to reduce errors and improve overall productivity.

Optimization starts at the design stage and extends through production and post-processing. Adopting best practices at every stage minimizes rework, reduces material waste, and ensures that parts meet both functional and regulatory requirements.

Scheduling and Workflow Integration

Hybrid manufacturing involves multiple stages that must be carefully sequenced to maintain quality and efficiency.

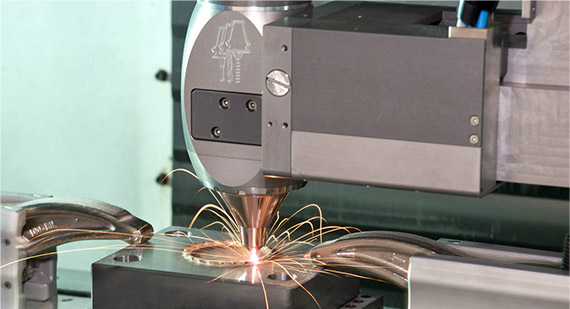

Additive and subtractive manufacturing

- Coordinating additive and subtractive steps

Plan the print-to-machine transition to minimize handling and potential distortion. Use digital models to verify fit before machining begins.

- Batch processing vs single-part production

Consider whether multiple parts can be printed and machined together or if individual part processing is required for accuracy.

- Timing of post-processing

Incorporate heat treatment, stress relief, and surface finishing into the schedule to prevent delays and maintain part stability.

Tool Selection and Machining Strategy

The choice of cutting tools, feeds, and speeds impacts surface finish, tolerance, and tool life.

- Adaptive toolpaths for irregular surfaces

Use scanned models of printed surfaces to generate adaptive roughing and finishing paths. This ensures consistent machining even on complex geometries.

- Tool material and coating selection

Select carbide, coated, or high-speed steel tools based on part material, hardness, and required surface quality.

- Minimizing tool deflection

Plan cutting directions and supports to avoid deflection, especially when machining thin walls or lightweight lattice structures.

Thermal and Stress Management

Thermal effects from both printing and machining can cause distortion or internal stress. Managing these factors improves part stability and precision.

- Heat control during machining

Optimize cutting parameters and cooling strategies to reduce thermal expansion and maintain dimensional accuracy.

- Stress analysis of printed features

Simulate internal stresses in printed regions to identify potential warping or cracking during machining.

- Staged machining for sensitive features

Machine critical surfaces first or in multiple steps to gradually relieve stress without compromising tolerances.

Documentation and Knowledge Management

Maintaining detailed records of process parameters, material batches, and machine settings supports repeatability and continuous improvement.

- Process documentation

Record printing orientation, layer parameters, support structures, and machining allowances.

- Inspection logs and deviation tracking

Capture measurements, defects, and corrective actions to refine future runs.

- Continuous improvement loops

Use lessons learned from completed parts to update design guidelines, toolpaths, and workflows.

Following these optimization practices ensures that hybrid manufacturing delivers predictable, high-quality results. It allows engineers to leverage the full potential of additive and subtractive processes while maintaining control over cost, time, and performance.

Conclusion

Hybrid manufacturing provides a powerful approach to producing complex parts with precision and efficiency. By combining additive manufacturing for geometric freedom with CNC machining for dimensional accuracy, engineers can create components that were previously difficult or impossible to manufacture.

Optimal results depend on careful planning at every stage. Designing parts for near-net printing, selecting suitable materials, managing printed-to-machined interfaces, and integrating proper inspection and quality control are all critical for success.

When implemented thoughtfully, hybrid workflows reduce material waste, shorten lead times, and allow for faster iteration without compromising performance. This approach is particularly valuable in aerospace, medical, and high-performance prototyping, where both complexity and precision are essential. By following best practices and focusing on process optimization, hybrid manufacturing can deliver parts that meet demanding functional and cost requirements efficiently.