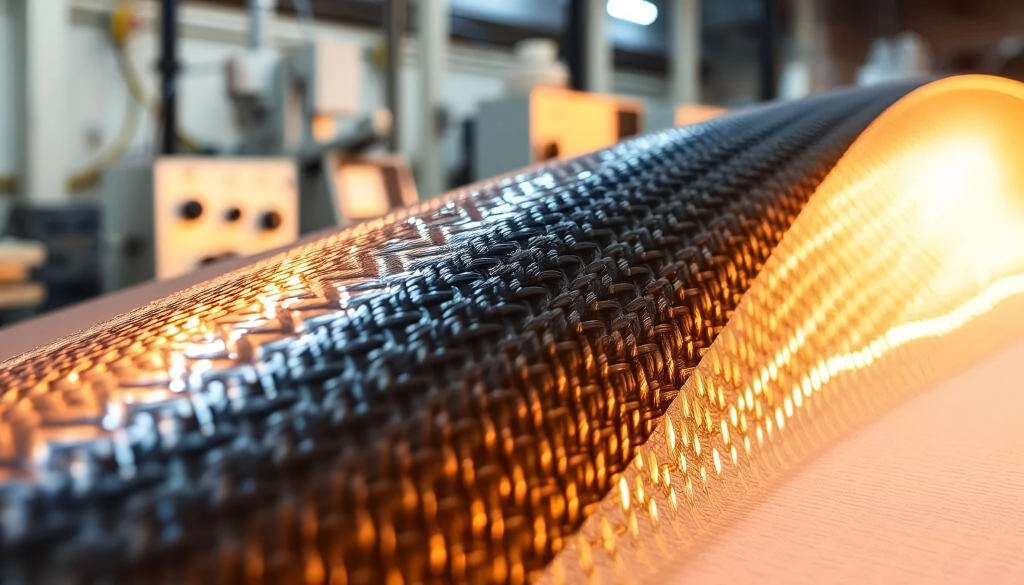

Carbon fiber's strength and lightweight features are unmatched, but they present machining challenges, including wear and delamination due to its anisotropic nature and thermal sensitivity.

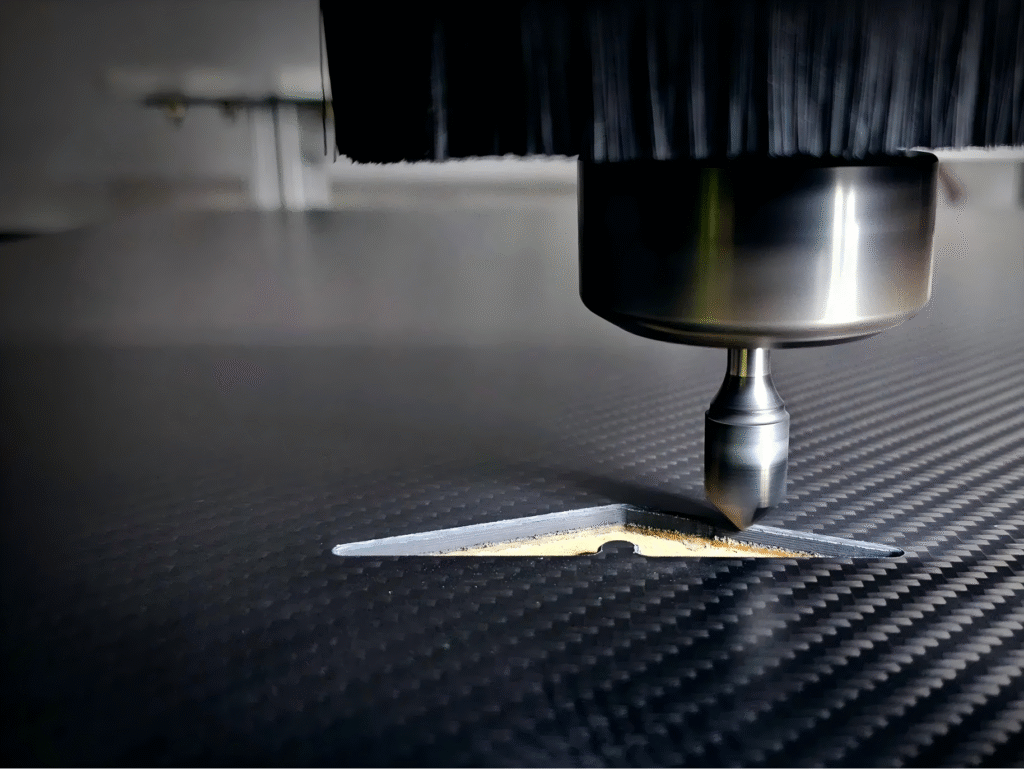

Achieving high precision in carbon fiber machining requires advanced CNC technology and specially coated tools. By carefully managing cutting speeds and feed rates, thermal issues and tool wear can be minimized.

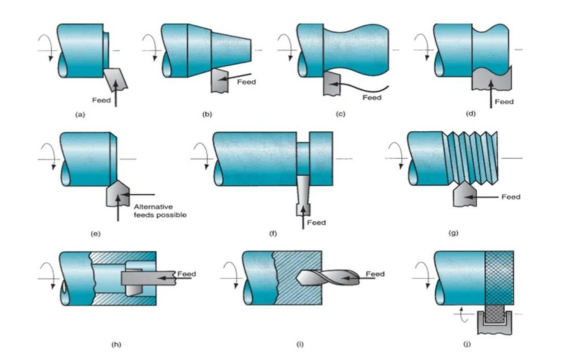

Carbon Fiber Machining Techniques

Carbon fiber machining demands precision to thrive in fields like aerospace and automotive, where it enhances performance and efficiency.

What Techniques Can Enhance the Precision of Carbon Fiber Machining?

Carbon fiber’s unique characteristics make precision challenging. Techniques to enhance its machining precision are crucial for successful outcomes in demanding applications.

Advanced CNC systems combined with laser-guided precision tools can greatly improve the machining accuracy of carbon fiber. Monitoring and adjusting for material-specific temperatures ensures clean cuts and surface integrity.

Enhancing Carbon Fiber Machining

To dive deeper into enhancing precision, let’s break it down into components:

Advanced CNC Systems: Implement CNC machines that offer higher speeds and adjustable feeds, tailored for carbon fiber’s unique properties.

Laser-Guided Tools: Using laser guidance can help with precision. They provide control, reducing human error.

Temperature Monitoring: Carbon fiber behaves differently at various temperatures. Tools like infrared thermometers help ensure optimal cutting conditions.

Each technique improves surface finish and dimensional accuracy, addressing issues like delamination and fiber pull-out.

What Tools Effectively Reduce Wear in Carbon Fiber Machining?

Wear is inevitable in carbon fiber machining. Tools that effectively minimize this prolonged tool life and maintain precision.

Using diamond-coated tools significantly reduces wear during carbon fiber machining due to their superior hardness. High-speed steel (HSS) tools with specialty coatings also enhance longevity.

Effective Tools

Consider the following tools for reducing wear:

| Tool Type | Benefits |

|---|---|

| Diamond-Coated Tools | High hardness; reduces tool wear |

| HSS Tools with Specialty Coatings | Improved resistance to friction and temperature |

| Carbide Tools | Offers durability; maintains edge sharpness |

Selecting the right tool material and coating can drastically improve performance and reduce machinery downtime.

What Are the Best Practices for Carbon Fiber Machining?

Best practices in carbon fiber machining ensure quality, efficiency, and cost-effectiveness. Implementing these practices can prevent common machining issues.

A thorough understanding of carbon fiber’s behavior is crucial. Employ gentle feed rates, cooling systems, and sharp, coated tools. Pre-machining analysis of fiber orientation reduces errors.

Efficient Carbon Fiber Practices

Here are the best practices to follow:

Gentle Feed Rates: Slower rates minimize heat build-up.

Cooling Systems: Use air or mist coolant to control temperature.

Sharp Tools: Regularly replaced or sharpened tools ensure efficient cuts.

Following these practices reduces delamination and enhances surface quality, crucial for high-performance parts.

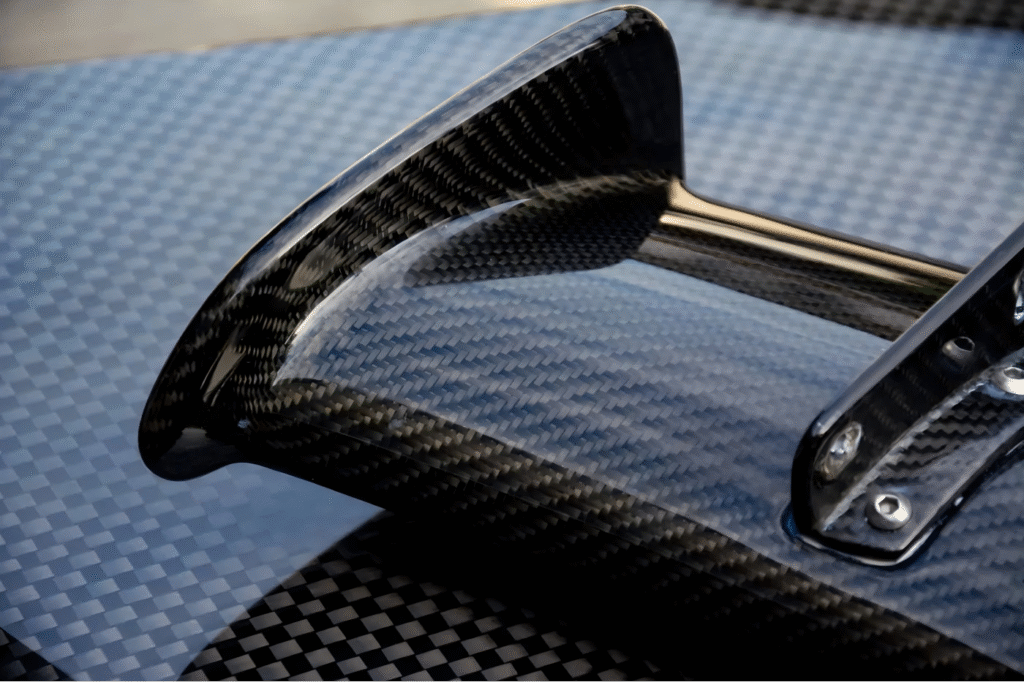

Which Application Areas Require Precision-Machined Carbon Fiber Parts?

Precision-machined carbon fiber parts are vital across multiple industries. Their demand is driven by the need for lightweight and strong materials.

Industries like aerospace, automotive, and medical devices rely heavily on carbon fiber precision for optimum performance. These applications demand fine tolerances and smooth finishes.

Industry Uses

Explore the main areas needing precision:

Aerospace: Light-weighting aircraft while maintaining structural integrity.

Automotive: Enhancing performance with lighter, more durable components.

Medical Devices: Precision ensures functionality in life-saving equipment.

Precise machining meets stringent industry standards, enhancing product efficiency.

What Are the Key Steps in Achieving Precision Machining of Carbon Fiber?

Precision machining of carbon fiber involves specific steps to meet quality standards and client expectations.

Key steps include selecting the right machine tools, optimizing parameters, and ensuring consistent environmental conditions. Real-time adjustments during machining ensure top-tier outcomes.

Here's a breakdown of essential steps:

Tool Selection: Choose diamond-coated or coated HSS tools.

Parameter Optimization: Adjust CNC parameters based on material responsiveness.

Environmental Control: Maintain stable conditions, focusing on temperature and humidity.

Real-Time Monitoring: Harness technology like AI for adjustments.

Each step contributes to achieving precise dimensional and surface quality without compromising efficiency.

Conclusion

Achieving high precision in carbon fiber machining entails using advanced tools, managing techniques, and following best practices across application areas for optimal performance and cost-efficient outcomes.